Policy Push: The EU’s “No More Diesel” Deadline Lights a Fire

Let’s cut to the chase: the EU’s Green Deal isn’t just environmental rhetoric—it’s a legally binding roadmap. By 2050, rail transport must slash greenhouse gas emissions by 90% compared to 1990 levels, and 75% of domestic freight needs to shift from roads to rails by 2030 .

That’s not a gentle nudge; it’s a mandate that’s turning railway electrification from a “someday” project into a “yesterday’s priority.” Operators don’t just want to go electric—they have to.

But here’s the punchline: only 57% of EU railway lines are electrified today . For the lines that are electrified, trains act like energy drama queens—guzzling power one minute and generating massive amounts the next.

When a train slams on the brakes (think of a TGV slowing for a station), it recovers 30-40% of the energy it used for acceleration. Without storage, though, most of that precious energy just burns off as heat—like leaving your phone charger plugged in while you’re on a two-week vacation .

The grid, meanwhile, panics at these sudden power surges and drops. It’s like a barista facing a rush of 100 latte orders at 8 AM, followed by 20 minutes of silence—no way to keep the system smooth.

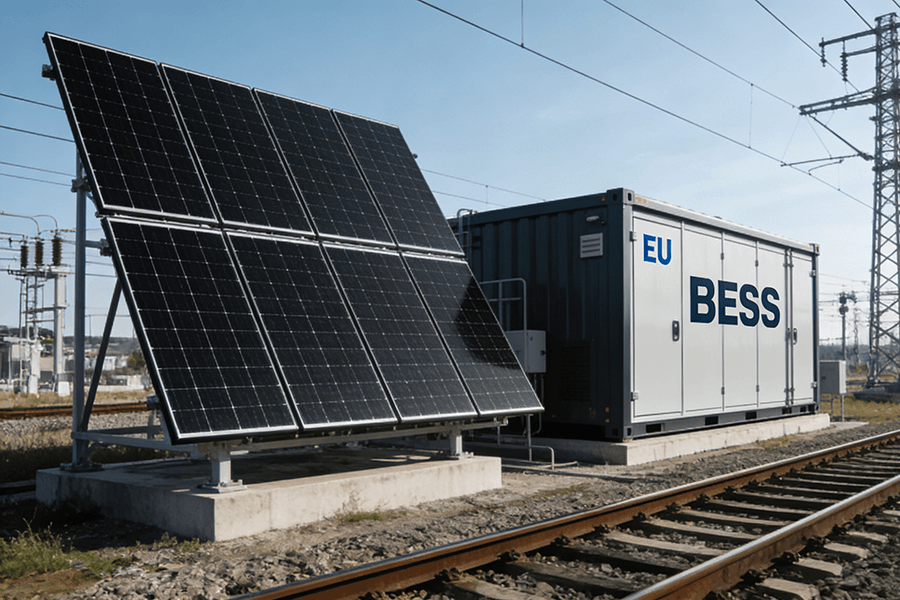

This chaos is why BESS containers are having a moment. The EU railway energy storage market is growing at a jaw-dropping 45% annually —and for good reason. Operators finally have a tool to stop wasting energy and keep the grid calm.

Key Takeaway: To hit those 2050 decarbonization goals, electrification alone isn’t enough. You need smart storage to make that electrification work efficiently.

Core Superpowers: What BESS Containers Actually Do (Spoiler: A Lot)

BESS containers aren’t just “batteries on steroids”—they’re multitasking wizards tailored for rail’s unique needs. Let’s break down their three biggest wins, with real-world numbers to back the hype:

Catch Regenerative Braking Energy (No More Wasted Heat!)

Trains generate massive energy when braking—enough to power a small town for several minutes. But without storage, it’s like pouring a full soda down the drain: frustrating and wasteful.

BESS containers step in as the “energy catcher.” They absorb that regenerative energy and feed it back to the grid or the next train that needs acceleration. The impact is tangible:

-

A Spanish suburban rail project cut energy use by 15% just by capturing braking energy .

-

Barcelona Metro goes even further: its BESS systems recover 41% of traction energy, saving 15 GWh annually—that’s the equivalent of 3,885 fewer tonnes of CO₂ floating around the city .

That’s not just efficiency—it’s turning waste into wealth.

Smooth Grid Spikes (Like a Barista with a Queue System)

When a high-speed train accelerates, it sucks power from the grid like a industrial vacuum cleaner. When it brakes, it dumps energy back like a bucket of water emptied in two seconds. This yo-yo effect is a nightmare for grid operators—it causes voltage fluctuations, increases maintenance costs, and even risks blackouts.

BESS containers act as the ultimate “grid buffer.” They absorb excess energy when trains brake and release it steadily when trains accelerate. The result? A 20% reduction in grid losses . For a large rail network, that translates to millions in annual savings—money that stays in operators’ pockets instead of being wasted on inefficiencies.

Emergency Backup (No More “Sorry, Train’s Stuck” Announcements)

Nothing kills passenger satisfaction faster than a sudden power outage. A single hour of train disruption costs operators up to €50,000 in delays, passenger refunds, and reputational damage . In busy urban areas like London or Berlin, that number can double.

BESS containers step in as emergency power banks. They automatically kick in during grid failures, keeping trains moving (or at least powering lights and air conditioning) until the main grid comes back. It’s like having a spare phone charger in your bag—you never think about it until you need it, and then you wonder how you lived without it.

|

BESS Superpower

|

Real-World Impact

|

Source

|

|---|---|---|

|

Regenerative Energy Capture

|

15% energy savings (Spanish suburban rail); 41% traction energy recovery (Barcelona Metro)

|

Ajuntament de Barcelona

|

|

Grid Stabilization

|

20% reduction in grid losses

|

CORDIS (E-Lobster Project)

|

|

Emergency Power

|

Avoids up to €50,000/hour in outage costs

|

Maxbo Solar Industry Analysis

|

Tech Talk: Why Not All BESS Containers Are Created Equal

You wouldn’t use a flip phone to run a startup—so why use a generic battery container for railways? Railway-grade BESS systems face unique challenges: extreme weather (from Scandinavian snow to Mediterranean heat), tight space constraints, and split-second energy demands. That’s why they need three non-negotiable features—these aren’t “nice specs”; they’re make-or-break for rail operators:

-

High Power Density: Trains need a burst of energy to accelerate—like a sprinter chugging a energy gel before a race. Generic batteries can’t deliver that instant oomph. Railway BESS containers have power-to-energy ratios (think 1 MW/0.5 MWh) that match those sudden demands . No more “lag” when the train hits the acceleration button.

-

Sub-Second Response Time: The grid doesn’t wait around—and neither do trains. Top-tier BESS containers adjust their output in under 100ms . That’s faster than the blink of an eye (which takes about 300ms) and fast enough to stabilize the grid even when 10 trains brake simultaneously at a busy station.

-

REM-S Compatibility: Railway Energy Management Systems (REM-S) are the “brain” of rail energy operations. If a BESS container can’t communicate with it, it’s just a fancy metal box. The best systems integrate seamlessly, sharing real-time data to optimize energy use—like a new employee who already knows how to use the office’s CRM and Slack on day one .

Case Studies: BESS Containers in Action (Spoiler: They Deliver)

Numbers on a page are great, but real-world projects? Even better. Let’s dive into two EU success stories that prove BESS containers aren’t just industry hype—they’re revenue boosters, efficiency heroes, and decarbonization tools.

Paris-Lyon High-Speed Rail: 12% More Capacity, Zero Extra Grid Stress

The Paris-Lyon TGV line is Europe’s busiest high-speed route—think of it as the “Times Square” of trains. Every day, 230 TGVs zip between the two cities, carrying 100,000 passengers . SNCF Réseau (France’s rail infrastructure manager) had a problem: it wanted to add more trains to meet demand, but the existing grid couldn’t handle the extra power load. It was a classic “have your cake and eat it too” dilemma.

Enter BESS containers. SNCF installed 10 containerized storage systems along the 425 km line, strategically placed near stations where trains brake and accelerate most frequently.

The system worked like a charm: BESS containers captured braking energy from incoming trains and stored it, then released it to power outgoing trains. No extra power needed from the grid—just recycled energy.

The result? A 12% increase in line capacity—that’s 28 more TGVs per day—without upgrading the grid. For SNCF, that means more tickets sold, more revenue, and happier passengers. It’s like adding a new lane to a highway without paving a single extra inch .

Madrid Metro: €800,000 in Annual Savings (Thanks to E-Lobster)

Madrid Metro’s E-Lobster project isn’t just a catchy name—it’s a game-changer for urban rail. The EU-funded initiative (part of the Horizon 2020 program) paired BESS containers with smart grid technology to connect the metro’s energy system directly to Madrid’s municipal power grid .

The goal? Turn the metro from an energy “consumer” into an energy “partner.” And it worked—beyond expectations.

-

€800,000 in annual electricity savings: By storing energy during off-peak hours (when prices are low) and using it during peak hours (when prices spike), Madrid Metro avoided overpaying for expensive grid power .

-

30% reduction in grid-related delays: The BESS system stabilized voltage fluctuations, which are a major cause of unexpected train stops .

-

15,000 fewer tonnes of CO₂ per year: By using more recycled braking energy and less fossil-fuel-generated grid power, the metro cut its carbon footprint significantly .

As Giannicola Loriga, E-Lobster coordinator, put it: “This isn’t just about storage—it’s about making rail and grid work together like a well-oiled machine” . We couldn’t agree more.

To summarize these wins, here’s a snapshot of the two projects’ key outcomes:

|

Project

|

Key Outcome 1

|

Key Outcome 2

|

Key Outcome 3

|

|---|---|---|---|

|

Paris-Lyon TGV

|

12% capacity increase

|

No grid upgrades needed

|

Higher passenger revenue

|

|

Madrid Metro E-Lobster

|

€800k/year savings

|

30% fewer delays

|

15k tonnes less CO₂/year

|

The Future: BESS + Rail + EV Charging = A Decarbonization Dream Team

Railway BESS containers aren’t stopping at powering trains—they’re about to become the backbone of multi-modal sustainable transport. The next big trend? Turning train stations into “energy hubs” that power not just trains, but electric vehicles (EVs) too.

Here’s how the vision works:

-

A train pulls into a station, brakes, and generates regenerative energy.

-

BESS containers capture and store that energy.

-

EV drivers at the station’s parking lot plug in their cars—powered by the train’s recycled energy.

It’s a closed-loop system: transport energy powers more transport. No waste, no extra grid strain, and a huge boost for EV adoption (a key part of the EU’s 2035 ban on new gasoline cars) .

This isn’t science fiction. In Germany, Deutsche Bahn is already testing this model at Berlin Hauptbahnhof, where BESS-stored rail energy powers 20 EV charging points . Early data shows the system cuts EV charging costs by 35% compared to grid-only power—proof that the dream team works.

Why Maxbo Solar Is Your Partner in This Journey

As someone who’s spent a decade in the renewable energy and storage space, I’ve seen firsthand how generic solutions fail in specialized industries like rail. That’s why at Maxbo Solar, we don’t just build BESS containers—we build BESS containers for railways.

Our systems are engineered to meet the EU’s strict rail standards (EN 50155, anyone?) and the unique demands of rail operations:

-

Custom Power Density: We tailor each system to match your trains’ acceleration and braking needs—no one-size-fits-all here.

-

Extreme Durability: Our containers handle -40°C to 60°C temperatures, heavy vibrations, and even the occasional graffiti tag (okay, maybe not the graffiti—but they’re tough).

-

Seamless REM-S Integration: We work with your existing energy management system, so you don’t have to overhaul your operations.

-

Proven EU Track Record: We’ve supplied systems for regional rail projects in Poland and Italy, delivering the same 15-20% efficiency gains you read about earlier.

But don’t just take my word for it. Head to www.maxbo-solar.com to see our case studies, technical specs, and even a virtual tour of our BESS production facility in Hungary. We’re not just selling equipment—we’re partnering with EU rail operators to hit those 2050 decarbonization goals, one container at a time.

Final Thought: The Future of Rail Is Stored

The EU’s rail revolution isn’t just about electrifying lines—it’s about making that electrification smart, efficient, and sustainable. BESS containers are the missing piece of the puzzle, turning wasted energy into savings, grid chaos into stability, and single-purpose rail into multi-modal energy hubs.

At Maxbo Solar, we’re ready to help you write your rail efficiency story. Let’s make 2050 not just a deadline, but a milestone.