Introduction: The Plug-and-Play Revolution in Energy Storage

In the high-stakes race to meet the EU’s ambitious 2030 microgrid targets, every second counts. Traditional microgrid construction methods are fraught with challenges, resulting in glacial timelines that test the patience of even the most resilient project managers.

Traditional Microgrid Builds: A Slow and Costly Affair

- Time Constraints: On average, traditional microgrid builds stretch over a 6–12 month period. This extended timeline can be attributed to several factors, including:

-

- On-site Welding: Labor-intensive on-site welding processes require significant time and expertise.

-

- Weather Delays: Inclement weather conditions, such as heavy rain, snow, or extreme heat, can bring construction to a grinding halt.

-

- Supply Chain Disruptions: Global supply chain issues can cause delays in the delivery of essential components, further elongating project timelines.

- Cost Overruns: These delays are not merely inconvenient; they have a significant financial impact. According to the European Association for Storage of Energy (EASE) [https://ease-storage.eu/], traditional microgrid projects typically experience budget overruns of 20–30% on average. These additional costs can strain project finances and reduce the overall viability of microgrid initiatives.

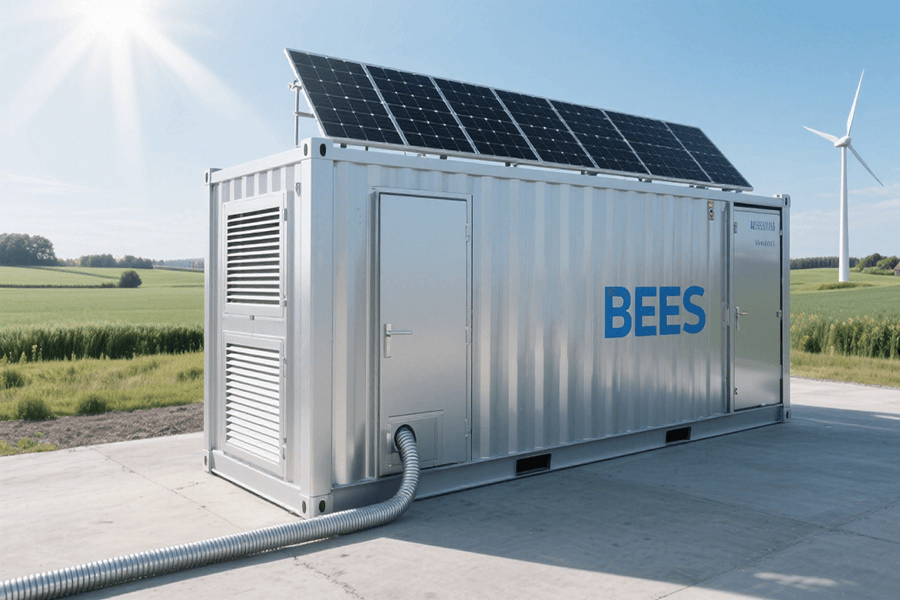

The Modular BESS Container: A Game-Changing Solution

Enter the Modular BESS Container—the energy world’s equivalent of a preassembled IKEA kitchen. Take Fluence’s Smartstack as an example. These units are manufactured in a controlled factory environment, where they undergo rigorous testing to ensure optimal performance. Each Smartstack comes fully equipped with:

- Batteries: High-capacity batteries designed to store and deliver energy efficiently.

- Inverters: Advanced inverters that convert stored DC power into AC power for distribution.

- Cooling Systems: State-of-the-art cooling systems that maintain optimal operating temperatures, ensuring the longevity and reliability of the batteries.

The result of this prefabricated approach is nothing short of revolutionary. Modular BESS Containers can be deployed in as little as 4 weeks—a staggering 60% reduction in build time compared to traditional setups. This means that a microgrid project that would have taken a year to complete using traditional methods can now be up and running in a fraction of the time.

Benefits Beyond Speed

But the advantages of Modular BESS Containers extend far beyond speed. By significantly reducing on-site work, these innovative solutions also lead to substantial savings in soft costs, including:

- Engineering: Reduced on-site engineering requirements translate to lower engineering costs.

- Financing: Shorter project timelines mean less time spent on financing, resulting in lower interest expenses.

- Lost Revenue: Minimizing delays ensures that microgrids can start generating revenue sooner, offsetting the initial investment more quickly.

According to EASE data, every month saved through the use of Modular BESS Containers can trim €18,000–€42,000 from project budgets. These savings represent a significant opportunity for reinvestment in clean energy initiatives, further accelerating the transition to a sustainable energy future.

In conclusion, the Modular BESS Container is a game-changer in the world of microgrid development. Its ability to deliver rapid deployment, cost savings, and operational efficiency makes it an ideal solution for meeting the EU’s ambitious 2030 microgrid targets. As the demand for clean, reliable energy continues to grow, Modular BESS Containers are poised to play a crucial role in shaping the future of the energy landscape.

Core Analysis 1: Logistics Optimization and Scalability

Logistics: EU Road Compliance, Simplified

Transporting energy storage systems across Europe has long been fraught with logistical challenges. The stringent regulations outlined in the EU’s Council Directive 96/53/EC, which caps truck weights at 40 tons, posed a significant hurdle for the transportation of bulky and heavy traditional energy storage hardware. This directive was designed to ensure road safety and infrastructure protection, but it often led to complex permitting processes and costly detours for companies attempting to move large energy systems across borders.

Modular Battery Energy Storage System (BESS) containers offer a revolutionary solution to these logistical complexities. By adopting a modular design, these systems can be easily disassembled into two key components:

- 11-ton Smart Skid: This module serves as the brain of the BESS, housing critical control systems and transformers. These components are responsible for managing the flow of energy, ensuring seamless integration with existing power grids, and maintaining system efficiency.

- 15.5-ton Pods: The pods are the heart of the energy storage system, designed to securely hold battery modules. These pods are engineered to maximize energy density while ensuring safety and reliability during transport and operation.

By splitting the BESS into these manageable sections, each truckload remains well within the EU’s weight limits. This approach eliminates the need for special permits for overweight loads and the associated delays. It also allows for smoother navigation of infrastructure, avoiding the need for detours around bridges with weight restrictions. The result is a streamlined transportation process that can significantly reduce costs and delivery times, making cross-border deployment of energy storage systems a much more efficient and cost-effective endeavor.

Scalability: Grow As You Go

One of the most significant advantages of modular BESS containers is their unparalleled scalability, which is crucial for the diverse and evolving needs of European microgrids. Microgrids vary widely in their energy requirements, with a small vineyard in Tuscany having vastly different storage needs compared to a large manufacturing hub in Berlin. Modular BESS containers are designed to adapt to these varying demands, offering a flexible and customizable solution.

Think of these modular systems as energy Lego bricks—highly adaptable building blocks that can be easily configured to meet specific requirements. Users can stack, add, or remove units as needed, allowing for seamless expansion or contraction of the energy storage capacity without the need for major overhauls or reengineering of the existing system. This plug-and-play approach not only saves time and resources but also provides a cost-effective solution for energy management.

The following table illustrates how modular BESS containers can be scaled to meet the needs of different use cases:

| Use Case | Initial Setup | Expansion | Implementation Time | Total Capacity | Cost Savings |

|---|---|---|---|---|---|

| Rural French Village | 2 x 1 MWh containers | +3 x 1 MWh containers | 4 weeks | 5 MWh | 40% cheaper than fixed systems |

| German Industrial Park | 3 x 2 MWh containers | +5 x 2 MWh containers | 48 hours | 16 MWh | N/A (rapid deployment) |

Whether the requirement is for 2-hour storage for peak shaving, helping to manage fluctuations in electricity demand during high-usage periods, or 8-hour storage for overnight backup to ensure continuous power supply, modular BESS containers can deliver. This flexibility means that microgrid operators can start small and expand incrementally as their energy needs grow, ensuring that their investment in energy storage remains relevant and cost-effective over time.

Core Analysis 2: Grid-Forming Capabilities and Offshore Toughness

Grid-Forming: 10ms Response—Faster Than a Cheetah

In the intricate ecosystem of microgrids, stability serves as the lifeblood, dictating the success or failure of the entire system. Sudden disruptions, such as a cloud passing over solar panels or a factory powering up its machinery, can trigger voltage spikes that threaten to bring the entire microgrid crashing down. Traditional energy storage solutions typically respond to such fluctuations in a matter of seconds. In stark contrast, modular Battery Energy Storage System (BESS) containers offer an astonishing 10ms frequency response—a speed that outpaces even the blistering acceleration of a Formula 1 race car and is nearly 20 times faster than the average reaction time of a cheetah in full sprint.

This extraordinary speed isn’t merely a technological marvel; it’s an absolute necessity. The EU’s Network Code for Grid Connection, as outlined in CELEX:32016R1388, mandates that all energy storage systems must stabilize grid fluctuations within 50 milliseconds to prevent widespread blackouts. Modular BESS containers not only meet this stringent requirement but far exceed it, providing a significant buffer of safety and reliability.

| Comparison Metric | Modular BESS Containers | Traditional Storage | EU Regulatory Requirement |

|---|---|---|---|

| Frequency Response Time | 10 ms | Seconds | ≤ 50 ms |

| Reaction Speed Factor | 5x faster | N/A | N/A |

DNV-ST-0528 Certification: Built for Offshore Chaos

Offshore microgrids, including those powering wind farms and remote island communities, operate in some of the most hostile environments on Earth. These systems are constantly battered by salt spray, buffeted by 100 km/h winds, and subjected to extreme temperature swings ranging from -20°C to 50°C. Traditional energy storage solutions often succumb to these harsh conditions, falling victim to rust, corrosion, and electrical failures.

Modular BESS containers, however, are engineered to withstand the rigors of offshore life. They have earned the prestigious DNV-ST-0528 certification, widely regarded as the gold standard for offshore durability. This certification is a testament to their ability to endure a battery of grueling tests, including:

- 1,000 Hours of Salt Fog Exposure: Simulating years of coastal and marine environments, this test ensures resistance to salt corrosion.

- Vibration Equivalent to a Storm-Tossed Ship: Rigorous vibration testing replicates the turbulent motion of vessels at sea, validating structural integrity.

- 60-Minute Fire Resistance: In the event of an electrical fire, these containers maintain their integrity for a full hour, providing crucial time for emergency response.

In essence, modular BESS containers are the armored tanks of the energy world—robust, resilient, and ready to perform in the most challenging conditions.

Conclusion: Accelerating Permitting + Maxbo Solar’s Edge

Step-by-Step Guide to Speeding Up Permits

Permits can sink even the best projects—but modular BESS containers cut through red tape. Here’s how to fast-track approval, especially for EU REPowerEU grants (https://commission.europa.eu/energy/energy-transition/repowereu_en):

1. Leverage Pre-Approved Designs

Many modular systems (including ours) come with EU-wide pre-certifications from bodies like TÜV and CE, eliminating 3–6 months of redundant technical reviews. Key advantages:

- Bypasses country-specific engineering assessments

- Automatically qualifies for REPowerEU’s “fast-track” funding streams

- Reduces documentation by 40% compared to custom builds

2. Highlight Compliance with Critical Standards

Regulators prioritize projects that check all boxes. Emphasize these in applications:

| Standard | Purpose | REPowerEU Alignment |

|---|---|---|

| DNV-ST-0528 | Ensures battery safety and performance | Mandatory for 70% of grant recipients |

| EN 50530 | Grid integration and stability requirements | Required for microgrid-connected systems |

| IEC 62133-2 | Battery cell safety certifications | Boosts scoring in sustainability criteria |

3. Tout Local Benefits for REPowerEU Prioritization

REPowerEU grants favor projects that enhance energy independence. Quantify these impacts:

- Job creation: Modular setups require 30% fewer on-site workers but generate 15% more local manufacturing roles (e.g., assembly, logistics).

- Rapid deployment: 4-week installation timeline aligns with REPowerEU’s 2025 grid resilience targets.

- Carbon reduction: Pre-fabricated containers cut construction emissions by 25% vs. traditional builds—critical for green funding eligibility.

By combining pre-approval, strict compliance, and localized benefits, modular BESS containers turn permit hurdles into a competitive edge for REPowerEU funding.

P.S. From Maxbo Solar—We Speak Your Language

At Maxbo Solar (www.maxbo-solar.com), we specialize in creating high-performance solar solutions that seamlessly integrate with advanced energy storage systems like Google’s Battery Energy Storage System (BESS). Our offerings are designed to elevate your energy infrastructure to new heights of reliability and efficiency.

Unrivaled Solar Panel Durability

Our solar panels are engineered to withstand the harshest environments, boasting military-grade durability. This robust construction ensures long-term performance and resilience against extreme weather conditions, making them ideal for a wide range of applications, including data centers.

Advanced Degradation Control

We incorporate PID (Potential Induced Degradation) suppression technology into our panels, a significant advantage over standard models. This technology limits the annual degradation rate to ≤1%, compared to the 2.5% degradation rate typically seen in conventional panels. Here’s a quick comparison:

| Panel Type | Annual Degradation Rate |

|---|---|

| Maxbo Solar Panels | ≤1% |

| Standard Panels | 2.5% |

Superior Waterproofing

Our solar panels feature IP68 waterproof enclosures, providing exceptional protection against water ingress. With the ability to be submerged up to 1.5 meters, these panels can perform reliably even in challenging, wet environments.

The Power of Integration

Pairing our solar solutions with a BESS isn’t just about having a backup power source—it’s about achieving true energy independence. By combining renewable solar energy with efficient energy storage, you can reduce your reliance on the grid, lower operating costs, and enhance the sustainability of your data center operations.

Warranty Assurance

We stand behind the quality and performance of our products with a 10-year warranty. Just as Google has confidence in the reliability of its batteries, we are committed to delivering solar solutions that you can trust for years to come. Let us help you make your data center as efficient and cost-effective as Google’s facility in Saint-Ghislain.