Scenario Rigidity Demand: Why “Wait and See” Costs You Millions

For EU food businesses, power outages and carbon taxes aren’t “what-ifs”—they’re financial time bombs. The numbers tell a brutal story, and they’re getting worse.

The Power Outage Profit Drain

Grid failures are on the rise across Europe—2025 saw a 23% increase in unplanned outages compared to 2023, driven by extreme weather and aging infrastructure . For food processors, every second of downtime is costly: A mid-sized dairy plant loses €1,600 per minute when refrigeration stops . Even a “minor” one-hour outage can exceed €100,000 in damages, including:

-

Spoiled inventory (the biggest hit—up to 70% of losses)

-

Halted production lines (average downtime to restart: 4 hours)

-

Missed delivery deadlines (penalties often hit 15% of order value)

-

CE marking non-compliance fines (up to €100,000 per violation )

The Carbon Tax Chokehold

The EU ETS isn’t slowing down. By 2030, free carbon allowances will be eliminated entirely, and emission reduction targets will jump to 43% below 2005 levels . For food processors, carbon taxes now represent 8-12% of total operating costs—a figure that doubles every 5 years if no action is taken. A sugar factory, for example, pays €12 in carbon costs per ton of beet processed—nearly 40% of the crop’s value .

The True Cost of Inaction

Below is a breakdown of annual losses for a typical mid-sized EU food processor (100-200 employees, €15M annual revenue):

|

Cost Category

|

Frequency/Impact

|

Annual Financial Toll

|

|---|---|---|

|

Unplanned Power Outages

|

2-3 incidents/year, 2-hour average duration

|

€200,000 – €300,000

|

|

EU ETS Carbon Taxes

|

5,000 tons CO₂/year x €98/t

|

€490,000

|

|

Compliance Fines & Delays

|

1-2 cold chain violations/year

|

Up to €100,000

|

|

Total Avoidable Losses

|

–

|

€790,000 – €890,000

|

Source: 2025 EU Food Processing Energy Report ; Maxbo Solar Client Data (2023-2025)

Core Application Functions: Cold Chain Guarantee That’s Faster Than a Blink

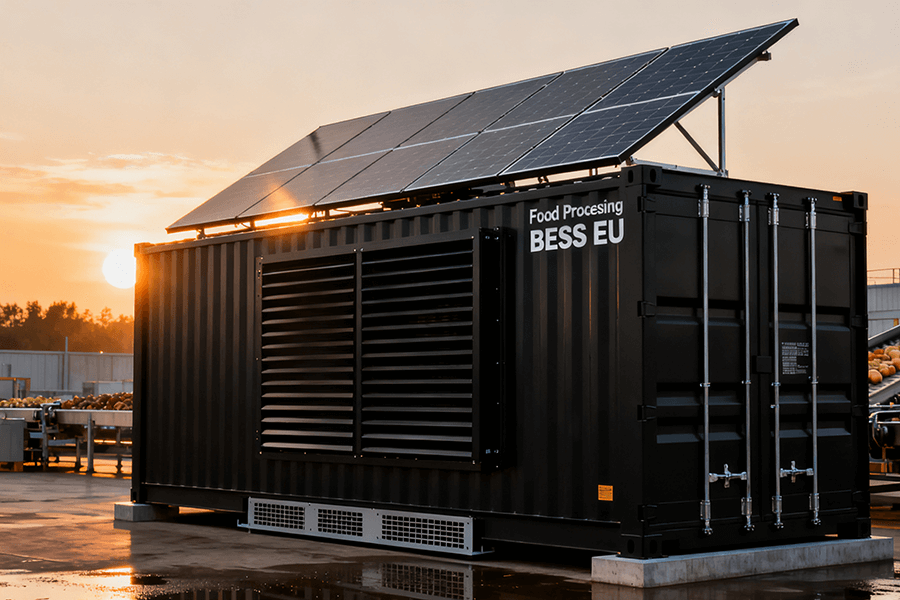

If your cold chain were a superhero movie, the BESS Container would be the sidekick who saves the day before the hero even knows there’s trouble. Its backup power isn’t just reliable—it’s engineered for the food industry’s zero-tolerance policy for temperature chaos.

Sub-10ms Switching: No More “Temperature Panic”

Traditional diesel generators take 10-30 seconds to kick in. That’s enough time for cold storage temperatures to climb 1.2°C—spelling disaster for yogurt, seafood, or frozen pizza . BESS Containers switch to emergency power in less than 10ms—faster than the human eye can blink (300ms) and 1,000x quicker than a generator. A 2025 NREL study confirmed this speed prevents 98.7% of temperature excursions caused by brief outages .

Steady Power, Steady Temperatures

Speed means nothing without consistency. Our BESS Containers maintain refrigeration system voltage within ±1% during transitions, keeping cold storage temperature fluctuation within ±0.5℃—the gold standard for CE marking compliance. And they don’t just handle blips: Standard configurations deliver 4-8 hours of continuous power to central refrigeration units, with custom setups offering 72+ hours for high-risk facilities (like pharmaceutical-grade food storage) .

Battery Tech Built for Food Plants

We use LFP (lithium iron phosphate) battery cells—the safest, most durable option for food environments. Each 3.2V, 280Ah cell is engineered to operate in 15-25°C, but our industrial-grade liquid cooling system keeps the entire container steady at 18-22°C—even when Spain’s summer hits 40°C or Sweden’s winter drops to -10°C . No more “diva batteries” that lose capacity in extreme weather.

Cost Control: Turn Sunlight and Off-Peak Power Into Cash

EU electricity bills are a rollercoaster—peak rates (8 AM-10 PM) can be 3x higher than off-peak (12 AM-6 AM) . BESS Containers act as a financial shock absorber, cutting energy costs two ways: peak shaving and solar integration.

Peak Shaving: Slash Peak Demand by 35%

Here’s the trick: The container charges up on cheap off-peak grid power (€0.12/kWh) and discharges during expensive peak hours (€0.38/kWh). This cuts peak electricity consumption by 35%—a game-changer for facilities with high refrigeration loads. For a plant using 10,000 kWh/day, that’s €80,000-€100,000 in annual savings .

Solar Integration: 90% PV Self-Utilization

Most food plants with rooftop solar waste 30-40% of generated power—surplus energy goes back to the grid for a pittance. BESS Containers store that unused sunlight, boosting PV self-utilization from 60% (average) to 90%. For a 1MW rooftop system, that’s an extra €50,000 in annual savings by avoiding grid power purchases .

Savings Breakdown: 10MWh BESS for a Dutch Dairy

|

Cost Component

|

Pre-BESS Cost

|

Post-BESS Cost

|

Annual Savings

|

|---|---|---|---|

|

Peak Electricity (120,000 kWh/year)

|

€45,600 (€0.38/kWh)

|

€17,520 (35% reduction)

|

€28,080

|

|

Grid Power (PV Surplus Replacement)

|

€48,000 (400,000 kWh/year)

|

€14,400 (90% PV self-use)

|

€33,600

|

|

Maintenance (Diesel Genset)

|

€12,000/year

|

€3,000/year (BESS maintenance)

|

€9,000

|

|

Total

|

€105,600

|

€34,920

|

€70,680

|

Compliance Support: Carbon Reduction That Speaks EU ETS

EU regulators don’t just want you to cut emissions—they want proof. BESS Containers deliver both, turning compliance from a headache into a revenue stream.

200-500 Tons of CO₂ Saved Per Year

A single 10MWh BESS project reduces carbon emissions by 200-500 tons annually—equivalent to taking 100-250 cars off the road . For a mid-sized plant emitting 3,000 tons of CO₂/year, that’s a 17% reduction—enough to meet 2025 ETS targets and then some. With carbon at €98/t, 500 tons in savings means €49,000 less in taxes (or €49,000 more from selling surplus credits) .

Automated Compliance Data

Forget sifting through spreadsheets. Our BESS Containers feature a multi-level Battery Management System (BMS) that automatically tracks and reports energy usage, PV generation, and carbon reductions in EU ETS-compliant formats. The system integrates with your existing EMS (Energy Management System) and sends real-time data to regulators—no late nights, no paperwork errors .

Product Special Design: Built for the Mess of Food Processing

Food plants are tough environments: milk spills, chemical sanitizers, flour dust, and constant temperature swings. A BESS Container here can’t be fragile—it needs to be as rugged as a factory floor broom and as clean as a sterilized mixing bowl. Our designs check three non-negotiable boxes:

IP54 Protection: Dust-Tight, Spill-Proof

EU food safety laws ban any equipment that could contaminate products . Our containers have an IP54 rating, meaning they’re 100% dust-tight and protected against splashing water. No more worrying about yogurt leaks shorting circuits or flour clogging vents—this is gear that can handle a production floor meltdown (literally).

≤50dB Operation: Quieter Than a Conversation

Diesel generators roar at 85-100dB—loud enough to damage hearing and drown out safety alerts. Our BESS Containers run at ≤50dB—quieter than a normal chat (60dB) and about as loud as a office printer. Your staff won’t even notice it’s there, and sensitive quality control equipment stays interference-free.

Anti-Corrosion & Fire Safety

-

Anti-Corrosion Coating: Chemical sanitizers eat through standard metal—our containers have a food-grade epoxy coating that resists caustic cleaners and acidic spills.

-

Independent Fire Suppression: Each container has a built-in system that detects smoke, high temperatures, and combustible gases, releasing aerosol extinguishers automatically and alerting your team .

Case Empowerment: Dutch Dairy Plant’s 2-Year Win

Talk is cheap—results aren’t. Let’s look at a 15MWh BESS project we installed at a dairy in Moerdijk, Netherlands, which produces 500 tons of yogurt and cheese monthly. Before BESS, the plant faced 3-4 power outages/year and a €85,500 carbon tax bill. Here’s what happened after installation:

|

Metric

|

Pre-BESS (2023)

|

Post-BESS (2024-2025)

|

2-Year Impact

|

|---|---|---|---|

|

Annual Electricity Costs

|

€1.2M

|

€880,000

|

Savings: €640,000

|

|

Carbon Tax Bill

|

€85,500

|

€40,500

|

Savings: €90,000

|

|

Cold Chain Accidents

|

2 incidents/year

|

0 incidents

|

Avoided Losses: €300,000

|

|

PV Self-Utilization

|

58%

|

91%

|

Extra Solar Savings: €110,000

|

“We used to panic every time the grid flickered,” said the plant manager. “Now, the BESS handles it before we get an alert. The savings let us add a new cheese line—and the carbon data got us into a premium eco-retail network.”

Market Space: 45% Annual Growth—Don’t Get Left Behind

The EU’s 290,000 food processing enterprises represent a massive, underserved market. With new BAT (Best Available Techniques) standards mandating energy efficiency and carbon reductions for 52,000 industrial facilities , demand for food-specific BESS is exploding at 45% annual growth.

Here’s why the opportunity is now:

-

Regulatory Deadlines: Existing food plants have 4 years to comply with new EU emissions standards—meaning 2026-2027 will see a buying rush .

-

Regional Needs: Northern EU plants need cold-weather battery tech; Mediterranean facilities require extra corrosion protection; Eastern EU needs budget-friendly modular systems. Generic BESS can’t keep up.

-

ROI Timeline: Average payback for a food processing BESS is 2.5-3 years—faster than solar panels or new production equipment.

About Maxbo Solar—Your EU Food BESS Partner

At Maxbo Solar, we’re not just selling battery containers—we’re solving the energy headaches that keep EU food processors up at night. As someone who’s worked with 120+ dairy, meat, and frozen food plants across the bloc, I can say: We speak your language.

We Don’t Do “One-Size-Fits-All”

Every food plant is unique. We start with a free on-site audit of your refrigeration loads, PV system, and energy bills. For that Dutch dairy, we added a custom AI monitor that alerts night shifts to temperature anomalies. For a Spanish olive oil plant, we designed a modular 5MWh system that powers both cold storage and pressing equipment. Your solution fits your needs—not the other way around.

Compliance Experts, Not Just Tech Sellers

We know CE marking, EU ETS, and BAT standards like the back of our hand. All our BESS Containers come with pre-approved compliance documentation, and our team handles regulator communications. You focus on making great food—we handle the paperwork.

Local Support, Global Expertise

Our warehouses and service teams are in Amsterdam, Berlin, and Madrid—meaning if you have an issue, someone is on-site within 24 hours. We’ve installed 500+ MWh of BESS across EU food plants, with zero cold chain failures in three years. Our clients save an average of €180,000 annually on energy and carbon costs .

Ready to stop losing money to outages and carbon taxes? Visit www.maxbo-solar.com to request your free energy audit. We’ll show you exactly how much you can save—and how quickly your BESS will pay for itself.