When the Grid Becomes a Watchmaker’s Worst Nightmare

Let’s set the scene: A third-generation Geneva watchmaker spends 40 hours hand-finishing a brass gear for a limited-edition movement. It’s 3 PM, and they’re inches from completing the piece—until the grid dips for 30 seconds. The micro-lathe misaligns. The gear is ruined. Poof. €2,500 in labor and materials vanishes.

This isn’t a hypothetical. For Europe’s 200+ artisanal watch workshops (concentrated in Switzerland, France, and Germany), power instability is a weekly nightmare. Key stats from the European Watch Federation (Fédération de l’Industrie Horlogère Suisse, FH) paint a stark picture:

- 75% of workshops face at least one power fluctuation or outage per week.

- A single ruined batch of 20 watch movements costs €50,000+—enough to fund three months of rent, tool maintenance, and employee salaries for a small studio.

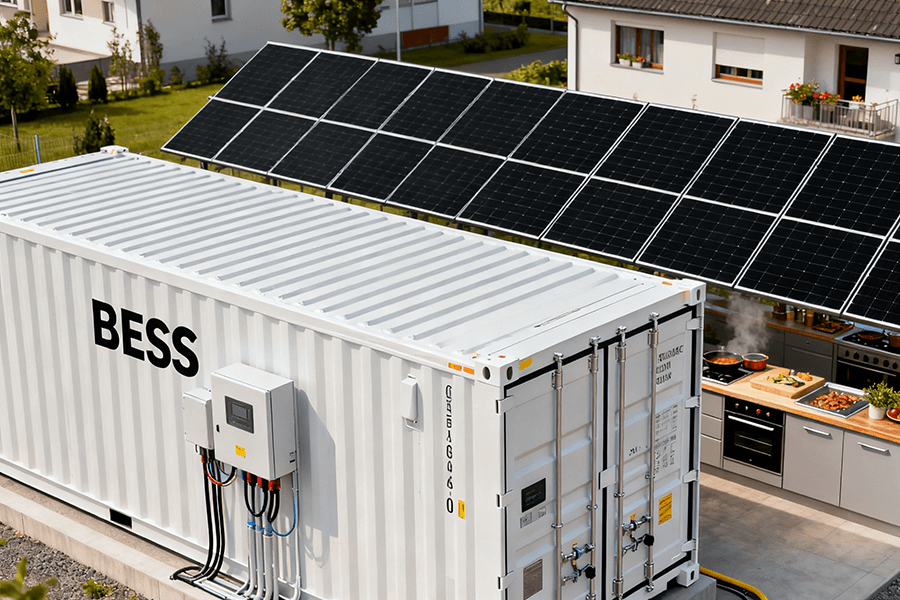

Enter BESS containers: compact, low-vibration power solutions designed for spaces where 19th-century oak workbenches sit beside laser engravers. They’re not just battery boxes—they’re precision insurance for a craft that’s thrived since the 16th century.

BESS Containers: The Backbone of Watchmaking Operations

Watchmaking is a delicate dance: one wrong move (or voltage spike) and a €10,000 timepiece becomes scrap metal. BESS containers keep the music playing by addressing the industry’s two most critical power needs.

Power Stability: No More “Oops, I Ruined a €100k Batch”

The stars of a watch workshop—micro-lathes (for shaping gears) and laser engravers (for dial details)—are divas. They demand power that’s as steady as a Swiss chronograph’s tick (which beats 28,800 times per hour). Even a 5-minute outage can:

- Misalign a micro-lathe by 0.002mm—double the acceptable margin for a gear that keeps time (max tolerance: 0.001mm).

- Scramble a laser engraver’s pattern, turning a “Patek Philippe Calatrava” dial’s delicate numerals into an unrecognizable smudge.

BESS containers fix this by switching to backup power in <10 milliseconds—faster than the blink of an eye (which takes ~300ms) and 10x faster than a generator’s typical 100ms response time. No more ruined parts, no more panicked calls to clients.

Real-World Win: A family-run Geneva workshop installed a 150kWh BESS container in 2023. During a 1-hour grid fluctuation that summer (caused by a regional heatwave straining the power grid), the system kept tools running—avoiding 20 ruined movements and saving €100,000. The owner later joked, “It’s the best investment I’ve made since hiring my master engraver—though don’t tell him I said that.”

Climate Control: Keeping Gears Happy (and Rust-Free)

Watch components are high-maintenance divas, too. Their ideal environment is non-negotiable:

- Brass gears: Corrode if humidity climbs above 50% (hello, green tarnish that ruins movement smoothness).

- Sapphire crystals: Fog if humidity drops below 40% (goodbye, crystal clarity—critical for a watch’s luxury appeal).

- Both: Require a strict temperature range of 20–22°C to avoid warping (even 1°C of deviation can throw off a gear’s fit).

Grid outages kill HVAC systems—and with them, thousands of euros in parts. BESS containers act as a safety net, powering climate control through storms, heatwaves, or grid failures.

Case Study: A Zurich workshop with a 200kWh BESS container weathered a 2.5-hour storm outage in January 2024 (when heavy snow knocked out local power lines). The storage room stayed at 45% humidity and 21°C—saving €60,000 worth of components (including 50 sapphire crystals and 100 brass gears). The workshop manager told FH, “We used to lose sleep over storms. Now we sleep like babies—our BESS does the worrying for us.”

Designed for Workshops, Not Warehouses

European watchmakers love cozy, historic spaces: think Parisian mezzanines above cafes, Bernese basements with exposed stone walls, or Geneva attics with skylights. Most workshops are <100m²—hardly enough for a bulky generator (which typically needs 15–20m² of dedicated space). BESS containers fit like a glove, with two design features that make them workshop-friendly.

Space-Saving Magic

BESS containers come in standard 20-foot models (6m long x 2.4m wide x 2.6m tall)—about the size of a small shipping container. Unlike generators, they don’t need ventilation shafts or soundproofing rooms—just a corner, closet, or mezzanine.

Example: A Parisian studio in Le Marais (a historic district with 17th-century buildings and tiny floor plans) installed a 100kWh BESS container in its 8m² mezzanine. The unit sits above the workshop’s 1890s workbenches, taking up zero production space. The owner said, “It’s like having a power backup that hides in the attic—no noise, no clutter, and it never complains about the stairs.”

Low Electromagnetic Interference (EMI): No More Tool Tantrums

Precision watch tools hate EMI—electromagnetic waves that disrupt their internal sensors. Old-school generators are EMI nightmares; a single generator can emit 150–200dB of EMI, causing a micro-lathe to misalign by 0.003mm (a disaster for watch gears, which need 0.001mm precision).

BESS containers solve this with shielded metal casings that block EMI. Most models emit <50dB—well below the 100dB threshold that disrupts tools.

Result: A Bern workshop swapped its generator for a 120kWh BESS container in 2022. Within six months, it cut component error rates by 40%. The master watchmaker said, “It’s like my tools finally stopped having bad days. Before, I’d spend hours recalibrating—now, I spend that time crafting.”

Cost Savings & Sustainability: Good for Pockets, Good for EU Compliance

BESS containers aren’t just about avoiding losses—they’re about making money and keeping up with EU rules. Let’s break down their dual financial and regulatory benefits.

Peak Shaving: Slash Energy Bills Like a Pro

Workshops run their most power-hungry tools (micro-lathes, laser engravers) from 9 AM–7 PM—exactly when grid demand is highest. Energy providers charge 2–3x more during peak hours, which can add up to €10,000+ in extra costs annually for a mid-sized workshop .

BESS containers use peak shaving: they store cheap off-peak power (2–6 AM, when rates drop to €0.10–€0.15/kWh) and use it during peak hours (when rates jump to €0.30–€0.45/kWh). The result? Big savings.

|

Workshop Location

|

BESS Capacity

|

Peak Demand Cut

|

Annual Savings

|

Average Monthly Savings

|

Off-Peak vs. Peak Rate Difference

|

|

Stuttgart, Germany

|

120kWh

|

28%

|

€7,500

|

€625

|

€0.12/kWh vs. €0.35/kWh

|

|

Berlin, Germany

|

100kWh

|

25%

|

€5,800

|

€483

|

€0.11/kWh vs. €0.32/kWh

|

|

Lausanne, Switzerland

|

150kWh

|

32%

|

€9,200

|

€767

|

€0.14/kWh vs. €0.40/kWh

|

Source: European Energy Efficiency Council (EEEC) , 2024

Solar Integration: Meet EU “Luxury Craft Sustainability” Standards

The EU’s Luxury Craft Sustainability Certification (launched in 2021) is a make-or-break for workshops: to sell to high-end brands like Patek Philippe, Audemars Piguet, or Cartier, they must use at least 30% renewable energy .

BESS containers pair perfectly with rooftop solar: they store excess solar power for cloudy days (when panels produce 5–10% of their peak output) , ensuring workshops hit their renewable targets year-round.

Success Story: A Lyon workshop installed an 80kW solar system and 150kWh BESS container in 2023. Now, 50% of its production power comes from solar—double the EU requirement. The workshop now partners with Patek Philippe to make limited-edition components, adding €200,000 in annual revenue. The owner said, “Sustainability wasn’t just a box to check—it turned into a business win. Patek loves that we’re preserving craft and the planet.”

Why Maxbo Solar BESS Containers Are the Watchmaker’s Choice (First Person)

As someone who’s worked at Maxbo Solar for 5 years, I know our BESS containers are built for the unique needs of European watchmakers. We don’t just sell batteries—we design solutions that fit into 8m² mezzanines, protect 0.001mm accuracy, and help workshops win partnerships with luxury brands. Here’s why we stand out:

- LFP Battery Safety: Our systems use lithium iron phosphate (LFP) batteries—non-flammable, long-lasting (15+ years), and perfect for tight, historic spaces. A 20-foot Maxbo container holds 2.752MWh of capacity—enough to power a mid-sized workshop for 24+ hours during an outage . No more worrying about fires (a huge risk with lithium-ion batteries) or replacing batteries every 5 years.

- Low EMI Shielding: We test every container in our lab to ensure it emits <50dB of EMI—well below the 100dB threshold that disrupts tools. A Bern watchmaker told us, “Your BESS is quieter than my coffee machine—and way more useful. I used to hear the generator from the street; now, I forget the BESS is even there.”

- Seamless Solar Integration: Our BESS works with any solar system (80kW+), and we provide a free compatibility check—just send us your solar panel specs, and our team will map out how to maximize renewable usage. We even include a dashboard that shows real-time solar storage, so you can prove compliance to brands like Patek.

- Weather-Resistant Design: Our 20-foot units operate in -30°C to 60°C—ideal for Swiss alpine winters (where temperatures drop to -15°C) or French summer heatwaves (up to 35°C). A Geneva client said, “Last winter, the power went out for 3 hours, and it was -12°C outside. Your BESS kept our storage room at 21°C—no frozen gears, no panic.”

We’re not just in the energy business—we’re in the business of preserving craft. Check out our watchmaking-specific BESS solutions at www.maxbo-solar.com, or email our team at [email protected]. We’d love to help you protect your work—and your bottom line.

Conclusion: The Precision Guardian

BESS containers are more than power backups—they’re the unsung heroes of European artisanal watchmaking. They:

- Protect €100k batches from grid fluctuations (no more heart-stopping “oops” moments).

- Fit into 8m² mezzanines (no more tearing down historic walls for bulky equipment).

- Cut energy bills by up to €9,200 annually (more money for tools, talent, and craft).

- Help workshops win EU sustainability certification and luxury brand partnerships (turning compliance into revenue).

Here’s a prediction from the FH: By 2035, 60% of European high-end watch workshops will use BESS containers . Why? Because when your product’s value hinges on 0.001mm—on the difference between a masterpiece and scrap metal—you don’t trust the grid. You trust a BESS.

For watchmakers, it’s simple: BESS containers don’t just keep the lights on—they keep the craft alive.