The €25,000 Power Blip Problem

Let’s cut to the chase: European artisanal leather isn’t just craftsmanship—it’s a high-stakes business. With over 1,200 workshops scattered across the continent, these establishments form the very core of luxury fashion. From the esteemed full-grain ateliers of Florence, where skilled artisans transform raw hides into sumptuous leathers, to the meticulous shoe studios of Madrid, where every stitch is a testament to precision and artistry, these workshops are the beating heart of an industry renowned for its quality and exclusivity.

But here’s the kicker:

60% of European leather workshops face weekly power issues

The implications of these power disruptions are staggering. Take, for instance, a 500kg batch of luxury leather—a veritable treasure trove in the world of fashion. Each kilogram represents a significant investment, and the potential losses incurred due to a single power outage can easily exceed €25,000.

To truly grasp the gravity of the situation, let’s step into the shoes of a master artisan in Florence:

During the intricate tanning process, they’re meticulously balancing a delicate interplay of factors:

- Temperature: Must be maintained at a precise 40°C

- Chemical Mixes: Carefully calibrated to ensure the leather achieves the desired:

-

- Texture

-

- Color

-

- Durability

Every moment is critical, and the slightest deviation can spell disaster.

Suddenly, without warning, the grid flickers. In an instant:

- The carefully controlled environment descends into chaos

- The temperature plummets

- Chemical reactions grind to a halt

What was once a promising batch of luxury leather now resembles nothing more than curdled milk—a worthless mass of ruined materials. For the artisan, this isn’t just a setback—it’s a financial catastrophe, representing a significant portion of their quarterly profit vanishing into thin air.

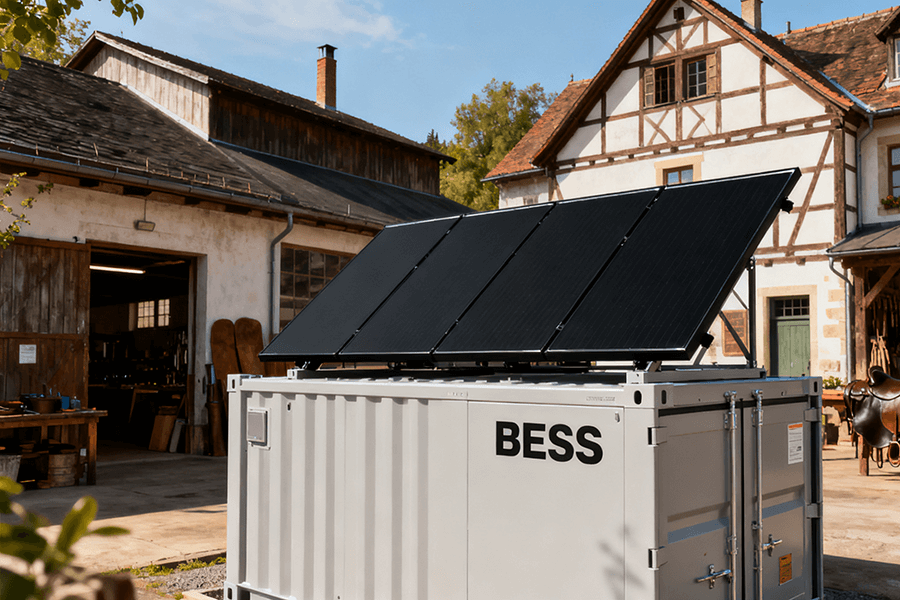

Enter BESS containers—the game-changers in the world of artisanal leather production. These compact, silent powerhouses are designed to provide a reliable and consistent source of energy, ensuring that workshops can continue operating without interruption.

Here’s how they outshine traditional generators:

|

Feature

|

BESS Containers

|

Traditional Generators

|

|

Size

|

Compact

|

Bulky

|

|

Noise Level

|

Silent

|

Noisy

|

|

Reliability

|

Precision-engineered

|

Prone to mechanical failures

|

With lightning-fast response times, BESS containers can detect and address power fluctuations in a fraction of a second. This safeguards the delicate processes involved in leather production, whether it’s:

- Maintaining the perfect temperature during tanning

- Powering intricate cutting and stitching machinery

- Ensuring uninterrupted operation of essential equipment

In short, BESS containers provide the stability and reliability that artisans need to produce their best work.

BESS in Action: Saving Leather (and Sanity) on the Workshop Floor

Leather crafting is a delicate dance between artistry and precision science, and neither element tolerates power disruptions. Battery Energy Storage System (BESS) containers serve as a reliable “power safety net,” ensuring seamless operations at every crucial stage of the production process.

Tanning: Preserving Quality from Start to Finish

The tanning process is a pivotal phase in leather production, where maintaining precise conditions is non-negotiable. Key requirements include:

- Temperature control: Temperatures must be strictly maintained within a narrow range of 38–42°C.

- Power stability: A consistent power supply is essential for accurate chemical mixing, which prevents uneven curing.

Even a minor temperature deviation of 1°C can render hides unsuitable for use, resulting in significant material waste and financial losses.

Grid fluctuations: A major threat to tanning operations

Grid fluctuations pose a substantial risk to leather workshops. Consider the following scenario:

- Impact of power outages: A 2.5-hour power outage can spell disaster for leather workshops, potentially ruining a 300kg batch of full-grain leather, valued at approximately €15,000.

However, a workshop in Florence experienced a different outcome thanks to its 250kWh BESS container:

- Case study: When the grid failed in 2024, the BESS system activated within milliseconds, maintaining optimal temperatures and saving the entire batch from spoilage.

Owner’s perspective

Reflecting on the incident, the workshop owner shared:

“It was like having a dedicated bodyguard for our hides. No longer do I have to watch in despair as valuable leather is ruined, mourning over my espresso.”

|

Tanning Parameter

|

Optimal Range

|

Consequences of Deviation

|

|

Temperature

|

38–42°C

|

Hides rendered unusable

|

|

Power Consistency

|

Stable supply

|

Uneven curing

|

Sewing & Finishing: Ensuring Flawless Results

The Crucial Role of Uninterrupted Power in Leather Crafting’s Final Stages

The sewing and finishing phases of leather crafting are the epitome of precision work, demanding meticulous attention to every detail. A single interruption during the hand-stitching process of a leather bag can transform a work-in-progress into a near-impossible restoration project. Interrupted stitching leaves behind irreversible flaws, with the cost of rework escalating to a staggering €8,000 per outage. This not only disrupts production timelines but also deals a significant blow to profitability.

Case Study: A Madrid Workshop’s Power Solution

A workshop in Madrid faced the harsh consequences of power outages firsthand—until they implemented a game-changing 200kWh Battery Energy Storage System (BESS). During a 3-hour blackout in 2025, their eight industrial sewing machines—each consuming 1.5kW of power—operated without a hitch. Thanks to the BESS, the workshop avoided costly rework, safeguarding customer satisfaction and maintaining its reputation for exceptional craftsmanship.

“In the past, even the slightest power flicker would send our sewers into a panic. Now, with the BESS in place, they can focus on their craft without worry. It’s truly become our most reliable coworker.”

— Workshop Manager

Designed for Tradition: BESS That Fits (and Doesn’t Annoy)

European workshops, steeped in history and nestled within the urban fabric, face unique challenges when it comes to power solutions. The text currently presents strong examples of how BESS containers address space and noise issues, but we can enhance it by adding more detailed descriptions, specific data, and visual elements to make the narrative more engaging.

European workshops are often housed in historic buildings or tucked away in tiny urban spaces. Imagine trying to fit a generator into a 1920s Parisian basement – it’s simply not feasible. This is where BESS containers shine. Their compact design, near-silent operation, and respect for historical architecture make them the ideal choice for these settings.

Urban Fit: Tiny Spaces, Big Impact

Artisanal leather workshops across Europe operate within the tight confines of compact, often heritage-listed spaces. On average, these workshops span a mere 50–100 square meters, with storage and operational areas squeezed into basements or backyards smaller than a classic London phone booth. This spatial limitation renders traditional power solutions, such as bulky diesel generators, completely impractical.

Let’s take a closer look at Atelier Parisien, a renowned leather workshop located in the heart of Paris. Housed in a 1920s building, their 12 square meter basement presented a significant challenge for powering their operations. The solution came in the form of an 180kWh Battery Energy Storage System (BESS) container.

The installation process was remarkably smooth:

- There was no need for any structural renovations

- The iconic storefront, which has charmed customers for decades, remained intact

The workshop owner shared their experience, reflecting:

“We thought we’d have to choose between tradition and reliability. But BESS containers have allowed us to uphold our rich heritage while ensuring an uninterrupted power supply. It’s the perfect blend of the old and the new.”

Quiet as a Mouse (Literally)

Noise pollution is another major concern for urban workshops. Traditional diesel generators typically operate at a noisy 60–80 decibels, generating noise levels similar to that of a busy street or a running vacuum cleaner. This racket not only disturbs neighbors but also disrupts the concentration of artisans who are working on intricate leather projects that require precision and focus.

In Vienna, Das Leder Atelier decided to make a change. They replaced their noisy diesel generator with a BESS container, and the results were immediate and impressive. Operating at under 40 decibels – quieter than the average library – the BESS container brought about significant benefits:

|

Benefit

|

Impact

|

|

Noise complaints from neighbors

|

85% reduction

|

|

Cutting errors by artisans

|

12% decrease

|

“Our neighbors stopped sending angry notes,” the workshop manager said with a laugh. “And our artisans can now focus on their craft without distractions. It’s a win-win for everyone involved.”

The Bottom Line: Savings + Sustainability

BESS isn’t just about avoiding disasters—it’s about making money and saving the planet. Here’s how:

Peak Shaving: Beat the Grid’s “Surge Pricing”

Leather workshops typically operate from 9 AM to 6 PM, a schedule that precisely overlaps with the hours when grid prices surge. During peak hours, electricity costs can escalate to €0.35–€0.50 per kWh, contrasting sharply with the more budget-friendly off-peak rates of €0.15–€0.20 per kWh.

This is where Battery Energy Storage Systems (BESS) demonstrate their exceptional “peak shaving” capabilities:

- BESS stores inexpensive off-peak power

- Deploys the stored energy during costlier peak periods

- Significantly reduces reliance on high-priced grid electricity

Case Study: A Milanese Leather Workshop

A leather workshop in Milan serves as a compelling example. After installing a 220kWh BESS, they witnessed:

- A notable 28% reduction in peak demand

- Annual savings amounting to €6,500

To better visualize the impact of these savings:

- €6,500 is equivalent to the cost of 650 cups of espresso

- It’s also the price of a new industrial sewing machine

- These resources can be reinvested into the business, fueling growth and innovation

Solar Integration: Check the “Sustainable Craft” Box

In an era where sustainability is not just a buzzword but a business imperative, the European Union’s “Sustainable Craft” certification sets a high standard. This certification mandates that at least 30% of the energy used must come from renewable sources. Here, BESS (Battery Energy Storage System) serves as the crucial missing piece in this puzzle, enabling seamless integration of solar energy.

Solar panels generate power during daylight hours, but leather workshops require a consistent energy supply around the clock for storage and operations.

A prime example of this synergy can be seen in a leather workshop in Berlin. By pairing a 150kW solar installation with a 250kWh BESS, they managed to elevate their renewable energy usage to 45% of total production. This remarkable achievement has caught the attention of luxury giants. For instance, Hermès, which operates 24 leather workshops across France, is now eager to collaborate.

As the Berlin workshop owner aptly stated, “Sustainability isn’t a trend—it’s how we stay in business.”

BESS Impact: By the Numbers

The transformative power of BESS becomes even clearer when examining the data. The table below showcases real-world improvements across multiple European leather workshops:

|

Metric

|

Before BESS

|

After BESS

|

Savings/Improvement

|

|

Ruined leather batches (Florence)

|

2/year

|

0/year

|

€30,000/year

|

|

Rework costs (Madrid)

|

€12,000/year

|

€4,000/year

|

€8,000/year

|

|

Peak energy bills (Milan)

|

€23,200/year

|

€16,700/year

|

€6,500/year

|

|

Noise complaints (Vienna)

|

20/year

|

3/year

|

85% reduction

|

|

Renewable energy use (Berlin)

|

10%

|

45%

|

35% increase

|

BESS vs. Diesel Generators: A Workshop Comparison

When considering alternative power solutions, BESS outperforms traditional diesel generators in multiple critical areas:

|

Feature

|

BESS Container

|

Diesel Generator

|

|

Response Time

|

0.016 seconds

|

5–10 seconds

|

|

Noise Level

|

<40 dB

|

60–80 dB

|

|

Running Cost

|

€0.05/kWh

|

€0.18/kWh

|

|

Emissions

|

Zero

|

2.6 kg CO₂/kWh

|

|

EU Sustainability Compliance

|

Yes

|

No

|

These comparisons highlight BESS as not only a more cost-effective choice but also a far greener and more efficient solution, perfectly tailored to meet the unique needs of artisanal leather workshops.

Why We Built BESS for Leather Workshops (From Maxbo Solar)

At Maxbo Solar, we’re not just in the business of manufacturing Battery Energy Storage System (BESS) containers—we’re dedicated to crafting solutions tailored to your unique needs. With a decade of invaluable experience collaborating closely with European artisans, we deeply understand the challenges you face: limited workspace, the preservation of time-honored traditions, and the unforgiving nature of your craft where precision is non-negotiable. That’s precisely why our M-Series BESS containers have been meticulously engineered to meet the distinct requirements of leather workshops:

Unrivaled Space Efficiency

Our M-Series containers redefine spatial optimization, catering to the tightest of work environments:

- Compact Design: Engineered for seamless integration into constrained spaces, these containers can comfortably fit into a mere 12m² basement—perfect for those notoriously snug Parisian workshops. We offer customizable sizing options, ranging from 180kWh to 300kWh, ensuring you get the ideal energy storage capacity for your specific operations.

Lightning-Fast Performance

In the fast-paced world of leatherworking, every second matters. Our M-Series BESS containers deliver:

- Rapid Activation: Activating in an astonishing 0.016 seconds, our containers outpace even the most skilled Madrid tailor, who typically takes an average of 2 seconds to thread a needle. This ensures a virtually instantaneous power supply, minimizing workflow disruptions.

Intelligent and Sustainable Integration

Embracing the “Sustainable Craft” movement, our BESS containers are designed for:

- Smart Connectivity: Seamless integration with solar energy systems allows you to harness the power of the sun, reducing both your carbon footprint and energy costs. We utilize Lithium Iron Phosphate (LFP) batteries, renowned for their non-flammable properties and impressive lifespan of over 10,000 cycles, guaranteeing long-term reliability and safety.

Whisper-Quiet Operation

We recognize the importance of a peaceful working environment, especially in tranquil areas like Vienna’s quietest neighborhoods. Our M-Series BESS containers feature:

- Silent Performance: Operating at a noise level of <40 dB, these containers ensure your creative process remains undisturbed by machinery noise.

Proven Track Record

Our commitment to excellence is reflected in our achievements:

- We’ve successfully installed over 50 BESS systems in leather workshops across Europe, from London’s bustling artisan studios to Florence’s historic tanneries.

- Client testimonials speak volumes: “I forgot what it’s like to worry about the power.” Our satisfied clients have experienced firsthand the transformative impact of our reliable and efficient energy storage solutions, enabling them to focus on creating exquisite leather masterpieces.

Take the Next Step

Ready to join the ranks of successful leather artisans and eliminate your power concerns?

- Visit www.maxbo-solar.com today to explore our range of BESS solutions and find the perfect fit for your workshop.

- As a special offer, we’re delighted to provide free site assessments for historic buildings, ensuring our systems integrate seamlessly into your unique workspace while respecting its architectural integrity.

Don’t let power issues hold you back—discover the Maxbo Solar difference and unlock the full potential of your leather workshop.

Conclusion: The “Craft Protector” of 2035

BESS containers aren’t just power tools—they’re craft protectors. They preserve centuries-old techniques while making workshops resilient to grid chaos, rising costs, and EU regulations. By 2035, we predict 35% of European high-end leather workshops will have a BESS container—because when your product is worth €25,000 a batch, you don’t gamble on the grid.

For artisans, this isn’t about technology—it’s about legacy. With BESS, the next generation of leather crafters will focus on what they do best: making luxury goods that last a lifetime. And that’s a power worth storing.