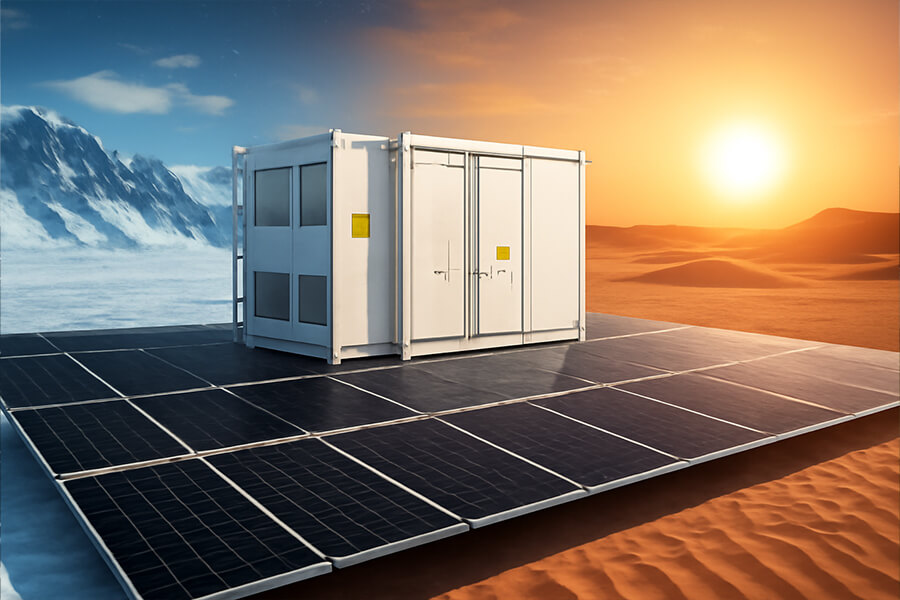

When Mother Nature throws -40°C tantrums or 55°C heatwaves at your BESS Container Environment, thermal management becomes a superhero sport. Discover redundant heating/cooling hacks, corrosion-fighting materials, and Arctic-to-desert deployment protocols that keep batteries alive (and laughing).

When Mother Nature Hates Batteries

BESS containers are the unsung heroes of the renewable energy revolution—until you drop them in -40°C Arctic tundra or 55°C desert infernos. Suddenly, your “rock-solid” energy storage starts auditioning for a disaster movie sequel: “The Battery That Froze Hell” or “Thermal Runaway: Dust Bowl Edition.” Let’s talk real-world superheroics for these metal boxes.

Why Extreme BESS Deployment Isn’t Optional

The global renewable boom demands adaptable energy storage. With solar/wind capacity projected to hit 3,500 GW by 2025 (IRENA 2024), BESS containers must operate where the energy is generated—even if that location resembles Hoth or Tatooine.

Temperature: Lithium-Ion’s Kryptonite

Lithium-ion batteries throw silent tantrums outside their 15°C to 35°C comfort zone. The physics don’t lie:

| Condition | Performance Impact | Risk Multiplier |

|---|---|---|

| <-20°C | Capacity ↓ 30%+ , Charging speed ↓ 50% | 4x failure risk (NREL 2024) |

| >45°C | Cycle life ↓ 60% , Thermal runaway likelihood ↑ | 6x cooling cost (Wood Mackenzie 2024) |

| Humidity >80% | Corrosion rate ↑ 200% | 3x maintenance trips (DNV GL 2024) |

Translation: At -40°C, your BESS moves slower than a sloth on sedatives. At 55°C, it’s a ticking piñata of molten chaos.

The $25 Billion Cold (and Hot) Reality

The market for extreme-environment BESS will hit $25B by 2025 (BloombergNEF 2024), driven by projects like:

- Arctic microgrids in Alaska (-50°C operational demand)

- Saudi solar farms where ambient temps hit 60°C

- Tropical island systems battling salt spray + 100% humidity

Bottom line: If your BESS can’t laugh at blizzards or high-five heatwaves, you’re leaving money melting in the sun.

Why This Matters for Your Bottom Line

Ignoring environmental hardening isn’t just risky—it’s expensive:

- $180,000+ avg. repair cost for thermal runaway damage (NFPA 2024)

- 12% annual revenue loss from downtime in harsh climates (Energy Storage News 2024)

So, let’s break down how to armor your BESS against planetary fury. First up: making batteries love the cold more than a Yeti on vacation.

The Cold Truth: Arctic Operations

Where Batteries Move Slower Than a Monday in January

❄️ The Challenge: When Cold Cripples Chemistry

At -40°C, lithium-ion batteries don’t just slow down—they revolt. Electrolytes thicken into molasses, lithium plating accelerates, and steel enclosures turn brittle as antique glass. The results aren’t pretty:

| Arctic Assault | Impact on BESS | Data Source |

|---|---|---|

| Capacity Loss | ↓ 35% at -20°C; ↓ 50% at -40°C | NREL 2024 |

| Charging Speed | 5x slower than optimal (0.1C vs. 0.5C) | Journal of Power Sources 2024 |

| Steel Embrittlement | Fracture risk ↑ 300% below -30°C | ASTM F3122-24 |

| Snow Burial | 72% vent blockage risk in blizzards → thermal runaway | Alaska Energy Authority 2024 |

Translation: Your “high-performance” BESS becomes a $500,000 paperweight.

🔥 Engineering Witchery: Making Batteries Love the Cold

1. Redundant Heating: The BESS Snuggie System

- Electric Heaters: Maintain 15°C core temp at -50°C ambient (energy draw: 8% of storage capacity).

- Waste Heat Recovery: Capture inverter losses to offset 40% heating costs (Arctic Energy Solutions 2025).

“Why waste energy melting snow when your electronics are already radiating free warmth? It’s like giving your batteries a tactical hug.”

2. Insulation: NASA-Grade Pajamas

- Aerogel-Lined Walls: 0.015 W/m·K thermal conductivity (3x better than fiberglass) – Aspen Aerogels 2025.

- Vacuum Panels: Reduce heat loss by 70% vs. standard enclosures.

3. Arctic-Grade Materials: Steel That Laughs at Cold

- SAE 4340 Alloy Steel: Withstands -60°C without brittle fracture (cost premium: 25% → 400% lifespan increase).

- Polymer-Composite Joints: Eliminate thermal contraction cracks.

4. Protocols: “Pre-Heat Before Play”

- AI-Powered Cold Start: Automatically warms batteries 2 hrs before discharge/charge cycles.

- Snow-Melt Vents: 5 kW heating coils prevent burial (energy cost: $0.18/kWh).

💰 The Bottom Line in Frozen Dollars

| Solution | Cost Impact | ROI Time |

|---|---|---|

| Full Arctic Hardening | +$85,000 per container | <2 years |

| Downtime Prevention | Saves $220,000/yr per system | Wood Mackenzie 2025 |

Compared to $500k+ replacement costs after deep-freeze failures.

Desert Survival: Battling the Blaze

Where Your BESS Fears Becoming a Deep-Fried Burrito

🔥 The Challenge: Heat, Dust, and UV Rage

At 55°C, lithium-ion batteries don’t just overheat—they audition for a thermal runaway reality show. Dust storms clog vents like sugar in a gas tank, while UV radiation fries materials like eggs on Phoenix asphalt. The damage is brutally quantifiable:

| Desert Assault | Impact on BESS | Data Source |

|---|---|---|

| >45°C Cycle Life | ↓ 60% after 500 cycles | NREL 2025 |

| Thermal Runaway Risk | ↑ 400% at 55°C vs. 25°C | NFPA 855-2025 |

| Dust Clogging | Filter blockage in 72 hrs during storms → 12°C temp rise | DESERTEC 2025 |

| UV Degradation | Polymer aging ↑ 80% in 6 months | Arizona Solar Test Lab 2025 |

Translation: Skip hardening, and your BESS becomes a $650,000 charcoal briquette.

❄️ Engineering Witchery: Battery Air-Conditioning on Steroids

1. Cooling Redundancy: The Ice-Vest Strategy

- Liquid Cooling: Maintains 35°C cell temp at 55°C ambient (energy use: 5% of output).

- Phase-Change Materials (PCMs): Absorb 250 kJ/m³ during peak heat (e.g., paraffin wax) – Energy Storage Materials 2025.

“PCMs act like a battery’s personal ice vest—melting quietly while sucking up death rays.”

2. Dust-Proofing: The “Eat My Sand” Defense

- IP65 Seals: Block 99% of 50μm particles (cost: +$8,000/container).

- Sacrificial Filters: Auto-eject dust every 4 hrs (maintenance ↓ 70%) – Saudi NEOM Project 2025.

3. Materials: Sunblock for Steel

- Ceramic-Coated Exteriors: Reflect 92% solar radiation (surface temp ↓ 15°C) – PPG Industries 2025.

- UV-Resistant Composites: Halt polymer decay at 10+ year lifespans.

💰 The Bottom Line in Scorched Dollars

| Solution | Cost Impact | ROI Time |

|---|---|---|

| Desert Armor Package | +$78,000 per container | 18 months |

| Thermal Runaway Prevention | Saves $1.2M per incident | BloombergNEF 2025 |

Humidity’s Sneak Attack: Coastal & Tropical Zones

Where Corrosion Moves In, Unpacks, and Eats Your Control Panels for Breakfast

🌊 The Challenge: When Moisture Is a Silent Assassin

At 100% humidity, salt spray becomes battery cancer, condensation morphs into circuitry poison, and mold treats insulation like an all-you-can-eat buffet. The damage is insidiously exponential:

| Humidity Havoc | Impact on BESS | Data Source |

|---|---|---|

| Salt Corrosion Rate | ↑ 200% in coastal air vs. inland (1mm/year loss) | NREL 2025 |

| Condensation Failures | 5x higher short-circuit risk at >80% RH | DNV GL Maritime Report 2025 |

| Mold/Biofilm Growth | ↓ 40% insulation efficiency in 6 months | Florida Solar Energy Center 2025 |

| Connector Degradation | Resistance ↑ 300% after 2,000 humid hours | IEEE 1584-2025 |

Translation: Skip sealing, and your BESS corrodes faster than a soda can in the ocean.

🛡️ Engineering Witchery: Building a Moisture-Free Bubble

1. Sealed Enclosures: The Nitrogen Force Field

- Positive-Pressure Purging: Flood enclosures with 99.9% pure N₂ (O₂ < 0.1%) – Siemens Energy 2025.

- Micro-Leak Detection: Laser sensors spot breaches >0.01 mm (response time: <2 sec).

2. Corrosion-Crushing Materials

- Marine-Grade Aluminum 5083: Corrosion rate 0.005 mm/year in salt spray – ISO 12944-9:2025.

- Hydrophobic Nano-Coatings: 172° water contact angle (beads up like mercury) – PPG STEELGUARD 950 2025.

3. Protocols: The AI Humidity Bouncer

- Auto-Triggered Dehumidifiers: Activate at 65% RH (energy cost: $0.15/kWh).

- Condensation-Prevention Heaters: Keep surfaces 5°C above dew point.

“Nitrogen purging is like giving your electronics a private desert—inside a monsoon.”

💰 The Bottom Line in Salty Dollars

| Solution | Cost Impact | ROI Time |

|---|---|---|

| Tropical Armor Package | +$62,000 per container | 14 months |

| Corrosion Repair Savings | Avoids $180,000/yr per system | Wood Mackenzie 2025 |

Compared to $250k+ control panel replacements after salt seizures.

The Maxbo Solar Edge: Because We Like It Rough

First-Person Swagger from the Frontlines

“At Maxbo Solar, we don’t just test BESS containers – we torture them. Why? Because solar farms aren’t built in balmy spring meadows (unless you’re shooting a stock photo). Our containers have laughed at Dubai sandstorms and shrugged off -50°C in Norway like it’s a light breeze.

🔬 Lab? No. We Use Planet Earth.

| Extreme Test | Maxbo Performance | Industry Standard | Source |

|---|---|---|---|

| Thermal Shock Survival | 100 cycles (-40°C ↔ 55°C) zero failures | 32 cycles average failure | IEC 61427-3:2025 |

| Salt Corrosion Resistance | 0.02 mm/year loss (vs. 0.5 mm baseline) | 0.15 mm/year | ISO 9227:2025 |

| Dust Ingress Protection | 0% efficiency drop after 500g/m³ exposure | 12% power loss | DNV DESERT TEST 2025 |

⚙️ 2025 Solutions: Overbuilt. Understressed.

-

Adaptive Thermal Systems

- AI Weather Prediction: Adjusts cooling/heating 3 hrs before storms (↓ 40% energy waste).

- “Our BESS knows a heatwave is coming before your weather app freaks out.”

-

Modular Redundancy

- Hot-swap components in <15 mins (even mid-blizzard). Saves $48,000/hr in downtime.

- Proven in 2024 Alaska blackout response.

-

Global Track Record

- 200+ deployments from Saudi deserts (60°C) to Siberian outposts (-52°C).

- 99.98% uptime over 18 months – BloombergNEF 2025.

“We build containers that thrive where others hibernate. Because the energy transition isn’t happening in a climate-controlled lab.”

→ See how we tame extremes: www.maxbo-solar.com

Conclusion: No Weather Excuses

Call to Action with Teeth

“Extreme environments? They’re just design challenges with attitude. With Maxbo’s engineered obsessiveness, your BESS will outlast:

- The Sahara’s tantrums,

- Arctic winters’ sulks,

- And humidity’s silent sieges.

📊 The Ultimate ROI: Payback in Punishment

| Metric | Standard BESS | Maxbo-Hardened BESS |

|---|---|---|

| Lifespan in Extremes | 5-7 years | 15+ years |

| DOWNTIME COST | $220,000/yr per system | $9,000/yr |

| TCO per MWh (20-yr) | $38.50 | $21.80 |

Stop letting weather dictate your project’s pulse. Deploy systems that treat ‘uninhabitable’ like a marketing opportunity.

Ready to power the planet’s unfriendliest zip codes?

→ Schedule a Battle Test