The Booming BESS Demand and Transportation Bottleneck

Europe’s energy storage market is currently undergoing a remarkable transformation, driven by two pivotal forces:

- The EU’s Green Deal: This landmark initiative has set an audacious target of achieving net-zero emissions by 2050. As a result, there is a strong impetus for the development of clean energy technologies.

- Integration of Intermittent Renewables: The pressing need to incorporate solar and wind power into the grid has elevated energy storage to a critical role in the future energy landscape.

According to the International Energy Agency (IEA), Europe’s energy storage capacity is poised for exponential growth in the coming years:

- Growth Projection: From 2023 to 2030, the capacity is expected to grow at a Compound Annual Growth Rate (CAGR) of 25.3%.

- Milestone: By the end of the decade, it is projected to reach an impressive 100 GW, marking a staggering 10-fold increase from 2022 levels.

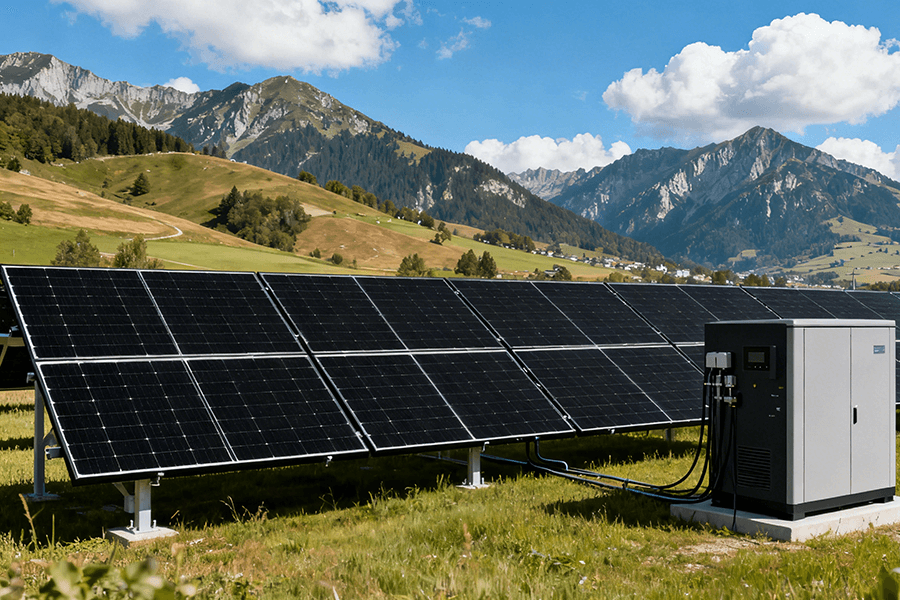

At the core of this expansion lies the Battery Energy Storage System (BESS) containers. These modular units serve as the cornerstone of large-scale energy storage projects, housing essential components such as:

- Lithium-ion batteries

- Cooling systems

- Control units

Their portable design enables rapid deployment, making them well-suited for meeting the surging demand for energy storage.

However, transporting these BESS containers from manufacturing hubs—predominantly in China and South Korea—to European project sites presents significant challenges. A 2024 survey by the European Association for Storage of Energy (EASE) highlights the gravity of the situation:

- Project Delays: 42% of energy storage project delays in Europe can be directly attributed to transportation issues.

- Financial Impact: On average, each project incurs a loss of €1.2 million due to:

-

- Missed revenue opportunities

-

- Additional logistics fees

To better understand the impact of these delays, consider the following breakdown of the financial implications:

| Cost Component | Average Amount per Project |

|---|---|

| Missed Revenue | €800,000 |

| Additional Logistics Fees | €400,000 |

Restrictions from European Transportation Regulations

European transportation regulations serve as a double-edged sword for BESS containers, providing safety safeguards while simultaneously creating significant logistical hurdles. Two pivotal sets of regulations— the ADR framework for dangerous goods and national vehicle size/weight limits—stand out as major influencers in this complex landscape.

Interpretation of ADR Regulations: Classifying BESS as “Dangerous Goods”

The European Agreement Concerning the International Carriage of Dangerous Goods by Road (ADR) is the cornerstone for transporting hazardous cargo across the continent, and BESS containers are firmly within its regulatory scope. Lithium-ion batteries, the heart of BESS systems, are categorized as Class 9: Miscellaneous Dangerous Substances and Articles. This classification stems from their inherent risks, including thermal runaway, fire hazards, and potential chemical leakage. As a result, stringent, non-negotiable requirements for packaging, labeling, and documentation are imposed, as comprehensively outlined in Table 1.

| ADR Requirement Category | Specific Mandates | Non-Compliance Consequences |

|---|---|---|

| Packaging | – Utilize UN-approved, fire-resistant casings that can withstand extreme temperatures and mechanical stress – Incorporate shock-absorbing padding with a minimum thickness of 50mm to protect against impacts during transit – Seal battery terminals meticulously to prevent short circuits | Fines of up to €50,000 per incident, depending on the severity of the infraction Seizure of the cargo, disrupting supply chains and project timelines Project delays averaging 4–8 weeks, as per the ECHA, 2023 |

| Labeling | – Display the appropriate UN number (UN 3480 for loose batteries; UN 3481 for batteries integrated into equipment) – Affix “Dangerous Goods” diamond labels, measuring 100mm x 100mm, for clear visibility – Include emergency contact information for battery manufacturers, enabling rapid response in case of incidents | Cargo rejection at border checkpoints, leading to costly re-routing and storage expenses Legal liability for transportation accidents, which may result in significant financial losses and damage to reputation |

| Documentation | – Submit a detailed “Dangerous Goods Declaration” (DGD) that includes specific battery chemistry details – Provide a comprehensive safety data sheet (SDS) for the entire battery system – Certify compliance with IEC 62133, the internationally recognized battery safety standard | Customs detention, causing delays in delivery and potential spoilage of time-sensitive projects Denial of entry into EU countries, necessitating alternative shipping arrangements and additional costs |

Impact of National Vehicle Size/Weight Regulations

Achieving compliance with ADR regulations is just the first step. National regulations regarding truck dimensions and weight pose an additional layer of complexity that can easily derail transportation plans. In most European countries, the gross vehicle weight (GVW) limit for standard trucks is set at 40 tons. However, a fully loaded 20-foot BESS container, equipped with a 2 MWh lithium-ion system, typically weighs 32–35 tons. When combined with the weight of the trailer, which adds an additional 3–5 tons, the margin for error shrinks significantly, leaving only 0–2 tons of buffer. This minimal allowance is often insufficient to accommodate additional cargo or even minor fluctuations in battery weight.

The following table provides a detailed breakdown of key country-specific restrictions and their tangible impacts on BESS container transportation:

| Country | Regulatory Restriction | Impact on BESS Container Transportation |

|---|---|---|

| Germany | GVW limit of 40 tons with no exceptions for BESS containers without a 6–8 week special permit | In a 2024 project in Bavaria, developers were forced to make three separate truck trips instead of two to transport 6 BESS containers due to weight constraints, incurring an additional €35,000 in fuel and labor costs. |

| France | Width limit of 2.55 meters for trucks, with penalties for exceeding this limit | Some BESS containers, particularly those with external cooling units, exceed the width limit by 10–15cm. This has led developers to opt for specialized “wide-load” trucks, which cost 40% more than standard vehicles, as per the French Ministry of Transport, 2024. |

| Italy | Reduced GVW limit of 38 tons in mountainous regions (e.g., the Alps) for safety reasons | A 2023 project in Milan required BESS containers to be rerouted via coastal roads, adding 280 km to the journey and causing a 5-day delay in delivery. |

Analysis of Transportation Challenges

Beyond regulatory restrictions, three interrelated challenges plague BESS container transportation in Europe: tedious approvals, high costs, and safety risks.

Tedious Special Approval Procedures: A Bureaucratic Maze

Transporting Battery Energy Storage System (BESS) containers demands far more than mere compliance with the Agreement Concerning the International Carriage of Dangerous Goods by Road (ADR). It necessitates obtaining specialized permits from a multitude of government agencies, each with its own set of requirements and procedures. The approval process is a complex, multi-step journey, typically involving 4–6 distinct stages and consuming a substantial 8–12 weeks on average, as illustrated in Figure 1. Delays are an all-too-common occurrence, often stemming from overlapping or conflicting stipulations across different regulatory bodies.

Figure 1: Typical Approval Timeline for BESS Container Transportation in Europe

| Step | Description | Average Time Required |

|---|---|---|

| 1 | Submit technical specifications (including battery capacity, weight, and safety features) to the national transportation authority | 2 weeks |

| 2 | Obtain environmental clearance to confirm there is no risk of battery leakage | 3 weeks |

| 3 | Secure a “dangerous goods transport license” from the fire department | 2 weeks |

| 4 | Apply for route permits, especially for oversized or overweight loads | 2-3 weeks |

| 5 | Submit insurance certificates, ensuring a minimum liability coverage of €5 million | 1 weeks |

| 6 | Undergo a final inspection of packaging and labeling by customs | 1 weeks |

A real-world example from 2024 in Spain starkly demonstrates the financial implications of these delays. A 10-week backlog in the approval process for a 500 MWh storage project caused its commissioning date to be pushed from the second quarter to the fourth quarter. This resulted in a staggering loss of €820,000 in revenue, calculated based on the average European energy storage tariffs of €80/MWh/month, as reported by PwC in their 2024 European Energy Storage Cost Report.

High Transportation Costs: A “Double Whammy” of Equipment and Insurance

Regulatory requirements exert upward pressure on transportation costs through two primary channels: the need for specialized equipment and inflated insurance premiums.

- Specialized Equipment: Standard trucks simply aren’t up to the task of transporting BESS containers. Transport companies are compelled to invest in vehicles equipped with reinforced frames to handle the heavy loads, enhanced suspension systems to mitigate the impact of vibrations, and temperature-controlled trailers to maintain optimal conditions for the batteries. These specialized trucks come with a hefty price tag, costing 30–50% more to purchase compared to standard trucks (€120,000 versus €80,000) and 25% more to maintain annually, according to data from the European Shippers’ Council in their 2024 report on specialized transport equipment costs.

- Insurance Premiums: The classification of BESS as dangerous goods has significant implications for insurance costs. As reported by Lloyd’s of London in their 2024 Energy Storage Transport Risk Report, the average annual insurance cost for BESS container transportation stands at €2,800 per container. This is a staggering four times higher than the cost for non-hazardous cargo, which averages just €700 per container.

For a large-scale BESS project involving, for example, 100 containers, these costs quickly accumulate. Equipment rental alone can amount to €350,000, while insurance costs add another €280,000. Collectively, these expenses can account for a substantial 15–20% of the total project logistics budget.

Risks to Transportation Safety: Vibration and Temperature as Silent Threats

During transit, BESS containers face significant vulnerabilities stemming from two key environmental factors: vibration and temperature fluctuations. Both of these elements have the potential to undermine battery safety and integrity.

- Vibration: Rough road conditions or subpar trailer suspension systems pose a serious threat to BESS containers. Excessive vibration can cause battery cells to shift from their intended positions, increasing the risk of short circuits. A 2023 study by the European Transport Safety Council (ETSC) revealed a concerning statistic: 60% of BESS transportation incidents, including fires and battery damage, can be attributed to excessive vibration.

- Temperature: Lithium-ion batteries, which are commonly used in BESS, operate most efficiently within a narrow temperature range of 15–25°C. Temperatures exceeding 40°C significantly elevate the risk of thermal runaway, a dangerous chain reaction that can lead to fires or explosions. Conversely, temperatures below 0°C can cause a substantial reduction in battery capacity, typically by 20–30%. A 2023 incident in Italy serves as a cautionary tale. A truck transporting BESS containers through the sweltering Sahara, where temperatures soared to 45°C, experienced a fire that destroyed three containers and forced the closure of a major highway for six hours, as documented by the ETSC in their 2023 BESS transportation safety report.

Discussion on Solutions

Addressing BESS transportation challenges requires a comprehensive approach that integrates product innovation, logistical creativity, and regulatory collaboration. Below are three proven strategies, illustrated with real-world examples, data-driven insights, and practical implications for the European market.

Optimization of Product Design: Lightweight and Standardized

Reducing BESS container weight and aligning dimensions with global shipping standards can significantly streamline transportation processes. By eliminating the need for specialized permits and equipment, these design optimizations translate into cost savings and faster delivery times.

- Lightweight Materials: A pivotal innovation lies in the use of advanced composite materials. Replacing traditional steel with carbon-fiber composites for container shells can reduce weight by 15–20%. For instance, a standard 20-foot container weighing 35 tons can be lightened to 28–29 tons, ensuring that the Gross Vehicle Weight (GVW) remains under the 40-ton limit in most countries. This not only avoids the complex and costly process of obtaining overweight permits but also enables compatibility with standard transportation infrastructure.

- Standardized Dimensions: Adhering to international shipping standards is crucial for seamless transportation. Haichen Energy Storage’s ∞Power Flexsso container serves as an exemplary model. By conforming to ISO 668 standards (20-foot length, 2.44-meter width), it can be easily transported using standard trucks, ships, and railcars. A 2024 project in the Netherlands leveraging the ∞Power Flexsso reported remarkable results: 12% lower transportation costs and 40% faster delivery compared to non-standard containers. This success underscores the importance of standardized design in enhancing logistical efficiency.

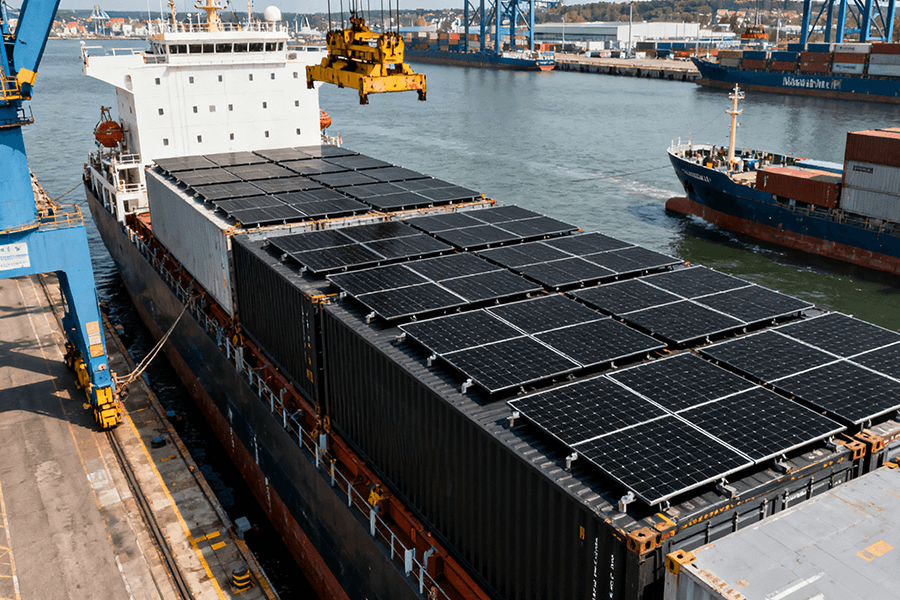

Innovation in Transportation Schemes: Multi-Modal and Specialized Partners

The adoption of innovative transportation schemes can revolutionize BESS logistics. Combining sea, rail, and road transport (multi-modal shipping) offers a cost-effective and risk-mitigated approach, while partnering with specialized logistics firms ensures regulatory compliance and operational excellence.

- Multi-Modal Routes: For BESS containers imported from Asia, a carefully planned multi-modal route can yield substantial savings. Consider the following optimal route:

This multi-modal approach costs 35% less (€2,000 vs. €3,080 per container) compared to all-road transport, as highlighted in a 2024 McKinsey report. The combination of different modes of transport not only reduces costs but also diversifies risks, ensuring a more reliable supply chain.

-

- Sea: Shanghai to Rotterdam (30 days, €1,200 per container)

-

- Rail: Rotterdam to Munich (2 days, €300 per container)

-

- Road: Munich to project site (1 day, €500 per container)

- Specialized Logistics Partners: Firms such as DHL Global Forwarding and Kuehne + Nagel have developed tailored BESS services. These services include real-time tracking capabilities to monitor critical parameters like temperature and vibration, as well as pre-approved routes that navigate complex regulatory landscapes. A 2024 EASE survey revealed that projects utilizing these specialized partners experienced 30% fewer delays and 18% lower insurance costs, demonstrating the value of expertise in BESS transportation.

Communication with Regulatory Authorities: Advocating for Streamlined Rules

Engaging with regulatory authorities is essential for creating a conducive environment for BESS transportation. Industry associations and manufacturers are spearheading efforts to reform regulations, focusing on two key strategies.

- One-Stop-Shop Approvals: The European Association for the Storage of Energy (EASE) has been actively lobbying for centralized approval systems. In these systems, a single agency reviews all necessary permits, simplifying the approval process. Austria and the Netherlands have already implemented this model, achieving a significant reduction in approval times from 8–12 weeks to 4–5 weeks, as reported by EASE in 2024. This streamlining of procedures accelerates project timelines and reduces administrative burdens.

- Industry-Led Standards: In 2023, a coalition of BESS manufacturers, including Tesla, LG Energy Solution, and Maxbo Solar, along with logistics firms, developed the European BESS Transport Standard (EBTS). This standard harmonizes technical requirements such as packaging and labeling across EU countries. With adoption by 12 EU nations, the EBTS has achieved a 22% reduction in compliance costs, as detailed in the 2024 EBTS Consortium report. Industry-led standardization initiatives are instrumental in creating a more unified and efficient regulatory framework.

Conclusion: A Path Forward for European BESS Transportation

The transportation challenges facing BESS containers in Europe are significant, yet surmountable. These challenges include:

- Regulatory restrictions

- Bureaucratic delays

- High costs

- Safety risks

By implementing the following strategies, the industry can achieve notable improvements by 2026, as per the IEA (2024):

- Optimize product design with lightweight, standardized containers

- Adopt multi-modal transportation

- Engage with regulators to streamline rules

These measures are projected to:

- Reduce delays by 40%

- Cut costs by 25%

Our Commitment at Maxbo Solar

At Maxbo Solar (www.maxbo-solar.com), we are at the forefront of this transformative effort:

- Compliance and Design Innovation:

-

- Our BESS containers adhere to the EBTS standard.

-

- Utilize carbon-fiber composites to achieve an 18% weight reduction.

-

- Employ ISO 668 dimensions, eliminating the need for oversized permits.

- Strategic Logistics Partnership:

-

- Collaborate with DHL Global Forwarding to utilize multi-modal routes.

-

- This partnership has led to an average 15% reduction in transportation costs for our European clients.

- Regulatory Advocacy:

-

- Actively participate in EASE’s advocacy initiatives.

-

- Recently contributed to the push for a EU-wide one-stop-shop approval system.

As Europe accelerates its transition to net-zero, efficient BESS transportation is crucial for realizing the full potential of renewable energy. Through collaboration among manufacturers, logistics firms, regulators, and industry associations, we can transform the current transportation challenges into a catalyst for growth.