Standard Urgency: Comply or Exit — Europe’s BESS Market Draws a Clear Line

The release of IEC 62933-4-3:2025 is like a “safety rectification order” for the European BESS industry. Different from the previous voluntary compliance standards, the EU explicitly stipulates in the “2025 New Energy Storage Development Plan” that all new BESS projects connected to the grid after January 1, 2026, must obtain IEC 62933-4-3 compliance certification. This regulation has quickly triggered a “shuffle effect” in the market, and the cases of project suspension and penalty due to non – compliance in France and Italy have sounded the alarm for global BESS suppliers.

The Heavy Cost of Non–Compliance: From Project Suspension to Market Ban

In 2025, the European market has witnessed multiple cases of non – compliant BESS projects suffering heavy losses, which fully demonstrates that “cutting corners on compliance” is a high – risk behavior with extremely low cost – effectiveness. The following are two typical cases sorted out based on the public information of the European Energy Regulatory Agency (ACER):

|

Project Information

|

Non – Compliance Issues

|

Consequences

|

Reference Source

|

|---|---|---|---|

|

50MW BESS Project, Catania, Italy (commissioned in March 2025)

|

Adopted containers meeting only IEC 62933-1 standard; key components failed to reach IP67 waterproof level; no seismic reinforcement design

|

1. Project suspended 3 weeks after commissioning due to water seepage and short circuit; 2. €12 million in equipment maintenance costs; 3. Lost €3.8 million annual grid subsidy; 4. 6 – month re – certification cycle

|

Italian Ministry of Economic Development, 2025.04 https://www.mise.gov.it

|

|

80MW BESS Project, Aix – en – Provence, France (final inspection in June 2025)

|

Surge Protection Device (SPD) nominal discharge current = 15kA, lower than the standard requirement of ≥20kA; grounding resistance = 6Ω, exceeding the limit of ≤4Ω

|

1. Project suspended before grid connection; 2. Daily loss of €210,000 due to delay; 3. Fined €500,000 by French Energy Regulatory Commission (CRE); 4. Missed the summer peak energy storage revenue period

|

French Energy Regulatory Commission (CRE), 2025.07 https://www.cre.fr

|

Compliance Investment vs. Non–Compliance Loss: A Clear–Cut Account

For project developers, the core concern is the “cost – effectiveness” of compliance. According to the data of Energy Storage Europe (ESE) 2025, the additional investment in compliance is only 5% – 8% of the total project cost, but it can avoid 90% of the potential risks. The specific comparison is as follows:

|

Indicator

|

50MW Utility – Scale BESS

|

20MW Commercial BESS

|

|---|---|---|

|

Total Project Cost (Non – Compliant)

|

€40 million

|

€16 million

|

|

Additional Investment for Compliance

|

€3.2 million (8%)

|

€0.8 million (5%)

|

|

Average Loss of Non – Compliance

|

€15 – 18 million

|

€4 – 6 million

|

|

Annual Revenue Increase from Compliance (Grid Preference + Subsidy)

|

€2.5 million (12% increase)

|

€0.7 million (9% increase)

|

|

Payback Period of Compliance Investment

|

16 months

|

14 months

|

Key Compliance Requirements: Decoding the “Seven Environmental Barriers” of IEC 62933-4-3

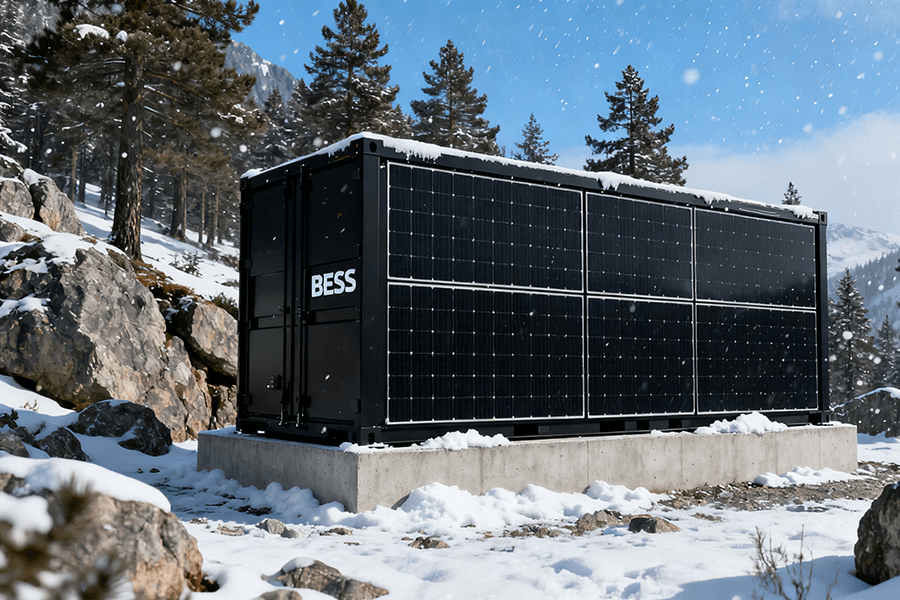

IEC 62933-4-3:2025 focuses on seven major environmental threat factors for BESS operations, including water intrusion, atmospheric corrosion, lightning strike, extreme temperature, humidity condensation, sand and dust erosion, and seismic vibration. Each requirement has clear quantitative indicators, which is equivalent to formulating a “survival manual” for BESS in harsh environments. Among them, the three high – risk scenarios below are the core of compliance, and also the pain points that many suppliers easily fail to pass.

Core Compliance Indicators and Technical Solutions

The standard abandons the vague description of “strengthening protection” and puts forward measurable technical indicators. The following table sorts out the key requirements and corresponding solutions, taking our compliant BESS containers as an example:

|

Compliance Dimension

|

Specific Standard Requirements

|

Our Technical Solutions

|

Europe – Oriented Value

|

|---|---|---|---|

|

Water Environment Protection

|

1. Key components (battery modules, converters) reach IP67; 2. Container installation height ≥0.5m above the historical flood level

|

1. One – piece sealed battery cabin with double – layer silicone gasket; 2. Galvanized steel support frame with height adjustable up to 1.2m; 3. Water immersion test for 30 minutes at 1m depth

|

Adapt to flood – prone areas such as the Netherlands (1 in 5 BESS sites face flood risk) and the British Thames Estuary

|

|

Atmospheric Corrosion Resistance

|

1. Pass 5000 – hour neutral salt spray test without rust; 2. Service life of external materials ≥15 years

|

1. 316L stainless steel for external panels (corrosion resistance 3 times that of 304 steel); 2. Fluorocarbon coating with 7 – layer spraying process; 3. Internal wiring with anti – oxidation tin plating

|

Solve the salt spray corrosion problem in Mediterranean coastal areas (regular steel rusts in 18 months)

|

|

Lightning Protection and Grounding

|

1. Grounding resistance ≤4Ω; 2. SPD nominal discharge current ≥20kA; 3. Lightning electromagnetic pulse (LEMP) shielding efficiency ≥80dB

|

1. Copper – clad steel grounding rod buried 2.5m deep (copper thickness 0.5mm); 2. Dual SPD protection (AC + DC circuit); 3. Galvanized steel mesh shielding layer for container body

|

Respond to frequent thunderstorms in Northern Europe (20 – 30 thunderstorm days per year) and Alpine areas

|

Other Key Environmental Protection Requirements

In addition to the three core dimensions above, the standard also has clear regulations on the other four environmental factors. These are like the “details that determine success or failure” in compliance, and cannot be ignored:

-

Extreme Temperature Adaptation: The operating temperature range is – 40°C to 65°C. Our solution adopts a “heat pump + phase change material” composite temperature control system, which can maintain the internal temperature of the container at 25 ± 5°C even in the minus 40°C polar vortex in Northern Europe.

-

Humidity and Condensation Control: The internal relative humidity must be ≤60%, and no condensation is allowed. We have installed a dehumidifier with automatic humidity control and a condensation water collection and discharge device to avoid circuit short circuits caused by condensation.

-

Sand and Dust Resistance: The external vents reach IP65 level. For areas with serious sand and dust such as the Spanish Meseta Plateau, we have added a three – layer filter screen (primary effect + medium effect + HEPA) to prevent sand and dust from entering the equipment.

-

Seismic Performance: It can withstand a seismic intensity of 7 degrees (0.3g acceleration). For seismic zones in southern Italy and Greece, we have adopted “seismic isolation brackets + flexible connecting wires” to ensure that the battery rack does not collapse during an earthquake.

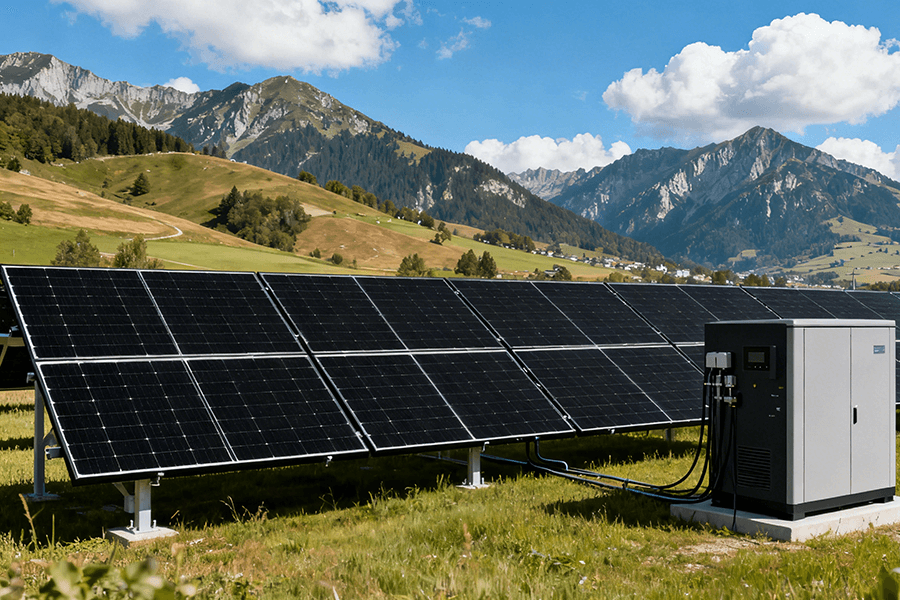

Regional Adaptation Solutions: Customized “Armor” for Europe’s Diverse Climates

Europe’s geography and climate are extremely diverse. A BESS container that works well in Norway may fail completely in Greece. Therefore, on the basis of meeting the unified IEC 62933-4-3 standard, we have launched regional customized solutions targeting the typical environmental characteristics of three key regions, achieving “standard compliance + regional adaptation”.

Three Major Regional Solutions and Performance Data

|

Target Region

|

Typical Environmental Challenges

|

Customized Upgrade Measures (Based on IEC 62933-4-3)

|

Verified Performance Results

|

|---|---|---|---|

|

Nordic Region (Norway, Sweden, Finland)

|

1. Winter temperature as low as – 40°C; 2. High humidity (annual average humidity 75%); 3. Short daylight hours (6 hours/day in winter)

|

1. Polyurethane foam insulation layer (thickness 150mm, R – value = 40); 2. Battery cabin pre – heater (automatically starts at – 10°C); 3. Solar – powered auxiliary heating system

|

In the 2025 Nordic polar vortex, the system operation efficiency remained at 98.7%, while non – customized containers only had 63% efficiency; no condensation phenomenon was found after 6 months of operation

|

|

Mediterranean Coastal Area (Spain, Greece, Cyprus)

|

1. High salt spray concentration (3 times that of inland); 2. Summer high temperature up to 45°C; 3. Strong UV radiation (annual UV index ≥8 for 8 months)

|

1. Double – layer 316L stainless steel outer panel; 2. UV – resistant PVDF coating (light retention rate ≥90% after 10 years); 3. Heat pipe – type natural cooling system (reducing energy consumption by 30%)

|

After 12 months of testing in Crete, Greece, the surface corrosion rate was 0; the container surface did not fade, and the internal temperature was 8°C lower than the external temperature

|

|

Southern Seismic Zone (Italy, Greece, Portugal)

|

1. Frequent earthquakes (magnitude 4 – 7); 2. Loose soil foundation; 3. Aftershock impact

|

1. Seismic isolation rubber pad at the bottom of the container; 2. Battery rack with triangular reinforcement structure; 3. Flexible cable connector (allowing 15° displacement)

|

In the 4.8 – magnitude earthquake in Naples, Italy in 2025, the system maintained normal operation; the battery rack displacement was ≤5mm, which was far lower than the standard limit of 20mm

|

Compliance Verification Path: How to Obtain the “EU Market Pass” Smoothly

Obtaining IEC 62933-4-3 certification is not a “one – time test” but a “full – process verification” recognized by EU authorities. The core is to pass the third – party certification of institutions such as TÜV Rheinland, SGS, and DNV. Among them, TÜV Rheinland, with 153 years of testing experience, is the most recognized certification body in the European market. Below, we take its certification process as an example to sort out the key steps.

Three–Stage Certification Process of TÜV Rheinland

-

Stage 1: Component and System Pre – Testing (4 – 6 Weeks)Test content: Conduct environmental stress tests on key components (batteries, converters, SPDs) and the entire system, including 100 – hour low – temperature operation (- 40°C), 5000 – hour salt spray test, and 20 times of simulated earthquake vibration.

-

Key deliverables: Component test report, system integration test report, and preliminary compliance evaluation opinion.

-

Stage 2: On – Site Risk Assessment (2 – 3 Weeks)Assessment content: Investigate the project site’s flood risk, soil conductivity, lightning frequency, and other environmental factors; review the project’s construction plan and maintenance system.

-

Key deliverables: On – site risk assessment report, with targeted improvement suggestions for non – compliant links.

-

Stage 3: Lifecycle Compliance Review (1 – 2 Weeks)Review content: Verify whether the enterprise has established a full – lifecycle compliance management system, including regular inspection plans (e.g., SPD replacement every 5 years), corrosion detection records, and emergency response plans.

-

Key deliverables: Formal IEC 62933-4-3 compliance certificate, valid for 3 years (annual re – inspection is required).

Red Flags in Certification: Be Alert to These Pitfalls

Some enterprises try to shorten the certification cycle by “falsifying test data” or “skipping on – site assessment”, but the consequences are extremely serious. In 2025, a German BESS startup was found to have forged salt spray test reports during the certification process. It was not only fined €5 million (4% of its annual revenue) by the EU but also banned from participating in EU public procurement projects for 3 years https://www.tuv.com. Therefore, “honest compliance” is the only correct path.

Case Studies & Outlook: Compliant Products Dominate the Market, and Maxbo Solar Leads the Charge

The market has proven that compliant BESS containers are not “expensive decorations” but “profit guarantee tools”. Two 200MW projects we participated in in the Netherlands and Norway have achieved remarkable results. As a core member of the IEC 62933-4-3 standard drafting working group, Maxbo Solar is not only a standard follower but also a market leader.

Two Typical 200MW Compliant Project Cases

|

Project Name

|

Location & Environmental Characteristics

|

Core Compliance Measures

|

Operation Performance (First 6 Months)

|

|---|---|---|---|

|

Zeeland BESS Project, Netherlands

|

Zeeland Province, located in the Rhine Estuary; annual flood risk; 120 rainy days per year

|

IP67 sealed battery cabin; 0.8m elevated installation; 316L stainless steel outer panel

|

1. Zero downtime during the July 2025 flood (water level reached 0.4m); 2. Energy conversion efficiency maintained at 92.3%; 3. Recognized as “Model Compliance Project” by the Dutch Ministry of Climate

|

|

Tromsø BESS Project, Norway

|

Tromsø, Northern Norway; winter temperature as low as – 35°C; 8 months of frost period

|

Composite insulation system; battery pre – heater; solar auxiliary heating

|

1. Average operation efficiency in winter is 98.1%; 2. Successfully supplied power to 12,000 households during the 2025 polar vortex; 3. Reduced heating energy consumption by 40% compared with local traditional projects

|

Maxbo Solar: From Standard Co–Drafting to Market Leading (First–Person Narrative)

As the Chief Technology Officer of Maxbo Solar, I have participated in the entire process of IEC 62933-4-3 standard discussion and drafting since 2023. This experience has made us deeply aware that “compliance” is not about passively meeting requirements, but about taking the initiative to define the safety baseline of the industry. For Maxbo Solar, our advantages in the European market are reflected in three aspects:

Technical Pre-emption: Taking the Lead in Realizing Mass Production of Compliant Products

As early as the draft of IEC 62933-4-3 was released in 2024, we invested €12 million in upgrading our R&D center in Shanghai, focusing on solving technical bottlenecks such as low – temperature battery activity and high – efficiency corrosion resistance. When the standard was officially released in May 2025, we had already completed the test verification of 5 container models and achieved mass production, which was 3 – 6 months ahead of our competitors.

Regional Layout: Building a Local Service Network in Europe

We have invested €20 million to build a production and after – sales base in Rotterdam, the Netherlands, which is expected to start production in early 2026 with an annual output of 1,000 compliant BESS containers. At the same time, we have established service centers in Oslo, Athens, and Milan, ensuring that after – sales response can be achieved within 24 hours. For European customers, this means “localized production + localized service”, which greatly reduces delivery cycles and maintenance costs.

Value–Added Services: Beyond Compliance to Create More Benefits

We do not stop at “meeting the standard”. For example, for Nordic customers, we have developed an AI – based predictive maintenance system that can automatically monitor battery performance and predict potential failures 30 days in advance; for Mediterranean customers, we have integrated a small – scale solar panel on the top of the container to provide power for the cooling system, reducing operating costs by 22% annually.

At present, our IEC 62933-4-3 compliant BESS containers have obtained certification from TÜV Rheinland, SGS, and DNV at the same time, and have signed supply contracts with European energy giants such as Statkraft and EDF with a total amount of €800 million. You can browse our full range of product specifications, certification reports, and project cases on our official website www.maxbo-solar.com, and our European team is always ready to provide you with customized solutions.

Market Outlook: 80% Market Share Will Be Captured by Compliant Products in 2027

According to the latest forecast report of LCP Delta, a well – known energy consulting firm, the European BESS market will enter a “compliance – driven” growth stage from 2026 to 2027. The specific trends are as follows:

-

By 2027, the market share of IEC 62933-4-3 compliant products will exceed 80%, and non – compliant products will only exist in small – scale off – grid projects.

-

The premium of compliant products will narrow from the current 12% to 5% – 8% in 2027, and the cost advantage of non – compliant products will completely disappear.

-

The European BESS market scale will grow from €12 billion in 2025 to €38 billion in 2027, with a compound annual growth rate of 55% https://www.lcpdelta.com.

For BESS suppliers, 2026 is a “critical window period” for entering the European market. Those who can quickly achieve compliance and realize localized services will seize the opportunity of market growth; while those who hesitate will inevitably be eliminated by the EU’s strict regulatory system and market competition.