- IEC 62619: The Sentinel of Battery Safety

-

- Functioning as the regulatory equivalent of a teacher’s red pen, IEC 62619 meticulously scrutinizes the safety of secondary lithium cells and batteries used in industrial applications, including BESS containers. This internationally recognized standard leaves no room for compromise, mandating that every component adheres to rigorous safety benchmarks. From thermal runaway prevention to short-circuit protection, IEC 62619 ensures that battery systems meet the highest safety criteria, effectively proclaiming, “When it comes to battery safety in the EU, compliance is non-negotiable.”

- VDE-AR-N 4105: The Maestro of Grid Integration

-

- Serving as the definitive grid code for the EU, VDE-AR-N 4105 outlines the technical requirements for connecting generators and energy storage systems to low-voltage distribution networks. Analogous to a skilled conductor guiding an orchestra, this regulation orchestrates the seamless integration of BESS containers into the grid. By specifying parameters such as voltage control, frequency regulation, and fault ride-through capabilities, VDE-AR-N 4105 ensures that energy storage systems operate in harmony with the grid, preventing disruptions and maintaining grid stability.

Core Analysis 1: Certification Roadmap

CE: The Golden Ticket to the EU Market

- Identify Applicable Directives:

-

- Low-Voltage Directive (LVD): This directive applies if the BESS contains electrical components operating within the specified voltage range. It sets safety requirements to prevent risks such as electric shock, fire, and mechanical hazards.

-

- Electromagnetic Compatibility Directive (EMC): Essential for ensuring that the BESS doesn’t emit excessive electromagnetic interference, which could disrupt other electronic devices. Additionally, it must also be immune to external electromagnetic disturbances to function reliably.

-

- Other Relevant Directives: Depending on the specific features and materials of the BESS, other directives like the RoHS (Restriction of Hazardous Substances) Directive, which restricts the use of certain hazardous materials, may also be applicable.

- Comprehensive Risk Assessment:

-

- Design Phase: Thoroughly analyze the BESS design for potential safety flaws. This includes examining electrical circuits for short circuits or overload risks, evaluating the structural integrity of the container to withstand transportation and operational conditions, and assessing the thermal management system to prevent overheating.

-

- Operational Phase: Identify hazards during normal operation, such as the risk of battery thermal runaway, potential electrical leakage, and the impact of external factors like extreme weather conditions on the system’s safety. Employ risk assessment tools and techniques, such as Failure Mode and Effects Analysis (FMEA), to systematically identify, analyze, and prioritize potential risks.

-

- Emergency Situations: Plan for worst-case scenarios, including battery fires, electrical faults, and system malfunctions. Develop emergency response procedures to minimize the impact on personnel, property, and the environment.

- Technical Documentation Compilation:

-

- Design Specifications: Provide detailed blueprints and technical drawings that clearly illustrate the BESS’s electrical, mechanical, and thermal design. Include information on component specifications, material properties, and system interfaces.

-

- Test Reports: Compile comprehensive test reports from accredited laboratories. These should cover electrical safety tests (e.g., insulation resistance, dielectric strength), electromagnetic compatibility tests (e.g., radiated and conducted emissions, immunity tests), and performance tests (e.g., energy storage capacity, charge/discharge efficiency).

-

- Compliance Records: Maintain records of compliance with relevant standards and directives. This includes certificates of conformity for individual components, documentation of internal quality control processes, and any corrective actions taken to address non-compliance issues.

- Declaration of Conformity (DoC):

-

- Preparation: Once all the necessary steps have been completed and the BESS has been verified to comply with the applicable directives and standards, prepare the Declaration of Conformity. This legal document declares that the product meets all the requirements for CE marking.

-

- Signing: The DoC must be signed by an authorized representative of the manufacturer or the importer. This individual assumes legal responsibility for the product’s compliance with EU regulations.

-

- Publication: Make the Declaration of Conformity available to relevant authorities and customers upon request. It should be stored for a specified period, typically 10 years, in case of any future compliance audits.

UL 9540A: Safety in the Face of Thermal Runaways

- Cell Overheating Response Testing:

- Safety Mechanism Validation:

UN38.3: Safe Travels for Batteries

- Vibration Tests:

- Shock Tests:

- Altitude Simulations:

Core Analysis 2: Grid Integration Features

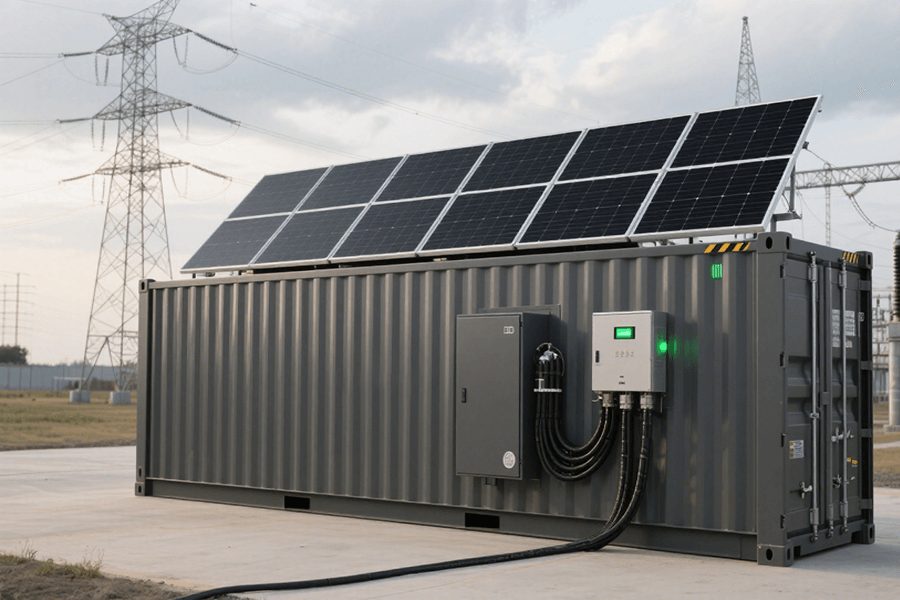

- Dynamic Power Management: Advanced control algorithms enable real-time power flow adjustments, ensuring seamless synchronization with grid frequency and voltage requirements

- Grid Support Services: Built-in capabilities for reactive power compensation and frequency regulation actively contribute to grid stability

- Safety Integration: Rigorous adherence to EU safety standards ensures secure operation, protecting both the grid infrastructure and surrounding environment

99.9% Harmonic Mitigation: Keeping the Grid’s Rhythm Steady

- Overheated Transformers: These vital components act as the grid’s power amplifiers. When harmonics enter the picture, transformers are forced to work overtime, leading to excessive heat generation. This not only significantly reduces their lifespan but also drives up maintenance costs, much like a musician’s instrument deteriorating faster due to improper tuning.

- Interference with Other Devices: Smart meters and renewable energy inverters are the grid’s modern virtuosos, relying on precise electrical signals to function optimally. However, harmonics can interfere with these signals, causing inaccuracies in energy measurement and reduced efficiency in power conversion, similar to a noisy backdrop drowning out a soloist’s performance.

10ms Frequency Response: Reacting Faster Than a Speeding Bullet

- Frequency Regulation: In the European Union, grid frequencies are required to stay within the narrow range of 50Hz ± 0.2Hz. The BESS’s lightning-quick response ensures that any deviations from this optimal range are corrected immediately, preventing potential damage to connected devices and maintaining the overall health of the grid.

- Blackout Prevention: Beyond frequency regulation, a 10ms response time is crucial for preventing blackouts. Whether it’s keeping the lights on during peak demand or ensuring that critical infrastructure—such as hospitals, data centers, and emergency services—remains powered, the BESS acts as a reliable safety net, minimizing the risk of widespread outages.

Safety Innovation: Fire Suppression Systems

How Novec 1230 Extinguishers Work

- Thermal Absorption: Novec 1230 rapidly absorbs heat from the combustion zone, effectively reducing the temperature below the ignition point of flammable materials.

- Cooling Effect: By rapidly vaporizing upon contact with the fire, the gas cools burning surfaces, preventing further fueling of the flames.

- Chemical Reaction Inhibition: The extinguisher interrupts the chemical reactions that sustain combustion, starving the fire of the oxygen and fuel required for propagation.

Key Advantages for BESS Applications

- Electrical Safety: As a non-conductive medium, Novec 1230 can safely suppress electrical fires without the risk of short-circuiting delicate electrical components, making it ideal for BESS units with complex wiring and high-voltage batteries.

- Environmentally Friendly: Unlike traditional halon-based extinguishers, Novec 1230 has zero ozone depletion potential and a low global warming potential, aligning with stringent environmental regulations.

- Rapid Deployment: The gas can be quickly dispersed throughout the BESS container, providing rapid fire suppression and minimizing downtime.

Compliance Checklist: EU Market Entry

Certifications

Certifications are the cornerstone of market access in the EU. They not only demonstrate your product’s safety and compliance but also build trust with consumers and regulatory authorities.

| Requirement | What to Verify | Additional Notes |

|---|---|---|

| CE Mark | The CE mark is a mandatory conformity marking for products sold within the EU single market. Ensure that all relevant EU directives are met, covering crucial aspects such as electromagnetic compatibility (EMC), low voltage safety, and machinery safety. This ensures your BESS container won’t interfere with other electrical devices, poses no risk of electric shock, and is safe for operation. | The CE mark serves as a passport for your product to enter the EU market, signaling to authorities and consumers alike that it meets essential safety, health, and environmental protection requirements. |

| UL 9540A Compliance | Lithium-ion batteries, commonly used in BESS containers, are susceptible to thermal runaway—a chain reaction that can lead to fires and explosions. Confirm that the BESS container meets the requirements of UL 9540A, which focuses on thermal runaway protection. This standard sets stringent criteria for battery management systems, enclosure design, and ventilation to prevent catastrophic battery failures. | Third-party testing and certification are typically required to validate compliance. These independent assessments provide an objective verification of your product’s safety features, giving you a competitive edge in the market. |

| UN38.3 Approval | The safe transport of lithium-ion batteries is a critical concern due to their potential hazards during transit. Obtain UN38.3 approval to ensure the safe transport of lithium-ion batteries used in your BESS containers. This approval covers various aspects of battery testing, including vibration, shock, thermal, and external short circuit tests. | This approval is required for both domestic and international shipping, ensuring that your product can be safely transported across EU member states and beyond. |

Grid Integration

Grid integration is vital for ensuring that your BESS container can operate harmoniously with the existing electrical infrastructure in the EU.

| Requirement | What to Verify | Testing and Validation |

|---|---|---|

| Harmonic Mitigation | Electrical harmonics can cause distortion in the electrical grid, leading to reduced efficiency, equipment damage, and potential safety risks. Verify that the BESS container can achieve 99.9% harmonic mitigation, ensuring low distortion levels in the electrical grid. This high level of mitigation helps maintain grid stability and the proper functioning of connected electrical devices. | Test reports from accredited laboratories are necessary to demonstrate compliance. These reports provide evidence of your product’s performance under real-world conditions, giving grid operators confidence in its integration. |

| Frequency Response |

Grid frequency stability is crucial for the reliable operation of the electrical system. Confirm that the system can respond within 10ms to frequency changes, as required for grid stability and reliability. A rapid response time enables the BESS container to quickly adjust its power output and help balance the grid during fluctuations.

|

Third-party testing and validation are recommended to ensure accurate results. These tests simulate various grid conditions to verify that your BESS container meets the stringent performance requirements of the EU grid. |

Safety

Safety is paramount when it comes to BESS containers, given the potential risks associated with lithium-ion batteries.

| Requirement | What to Verify | Implementation and Testing |

|---|---|---|

| Fire Suppression | Lithium-ion battery fires are particularly challenging to extinguish due to their high energy density and self-sustaining nature. Ensure the installation, calibration, and testing of the Novec 1230 fire suppression system, which meets EU fire safety norms. Novec 1230 is a clean agent that effectively suppresses fires without leaving residue, minimizing damage to the BESS container and surrounding equipment. | Regular maintenance and periodic testing are essential to ensure the system’s effectiveness. This includes checking the integrity of the suppression system, verifying the proper functioning of sensors and actuators, and conducting fire drills to ensure personnel readiness in case of an emergency. |

About Maxbo Solar

- CE, UL 9540A, and UN38.3 certified—no shortcuts, just rigorous testing.

- 99.9% harmonic mitigation and 10ms response times—we don’t just meet grid codes, we set the bar.

- Top-tier Novec 1230 fire systems—because safety isn’t optional, it’s our priority.