Introduction: The “Energy Headache” of Traditional European Port Logistics

European ports—responsible for handling over 75% of the continent’s external trade (Eurostat, 2025)—find themselves grappling with a formidable dual crisis: exorbitant energy consumption and crippling peak power costs. At the heart of this challenge lie RTG (Rubber-Tired Gantry) cranes, the indispensable workhorses of container handling operations. A closer look at their energy consumption patterns reveals inefficiencies that are not only environmentally concerning but also financially burdensome.

Key Pain Points of Traditional RTG Operations:

| Aspect of Operation | Energy Consumption Metrics | Financial Impact |

|---|---|---|

| Insane Energy Guzzling | A single RTG crane tasked with lifting 40-ton containers consumes approximately 150 – 200 kWh/hour (Port Technology Opex Benchmark 2025). To contextualize this staggering figure, it’s sufficient energy to power 15 average suburban homes for an entire day. For ports equipped with 20 or more cranes, the monthly energy expenditure for lift operations alone surpasses €120,000. | High energy costs inflate operational budgets, squeezing profit margins. |

| Wasted Regenerative Energy | When RTG cranes lower containers, they generate 25 – 40% of the lift energy as electricity—a potentially valuable, “free” energy source. However, in traditional setups, this generated power is squandered as heat through brake resistors. According to the Hamburg Port Authority’s 2024 report (p.12), a single crane wastes 350 – 500 kWh/day in this manner. This translates to a daily financial loss equivalent to 55,000 annually per crane. | Missed opportunity for cost savings and revenue generation from recovered energy. |

| Devastating Peak Charges | Ports experience intense operational periods, particularly between 9 am and 5 pm, often referred to as “crane rush hour.” During these times, grid demand surges, prompting utilities to impose peak shaving surcharges. These surcharges can inflate electricity bills by 60 – 300% (Maritime Energy Pricing Index 2025). In 2025, 70% of European ports reported monthly peak charges exceeding $45,000 per terminal. | Additional financial strain on port operations during peak activity periods. |

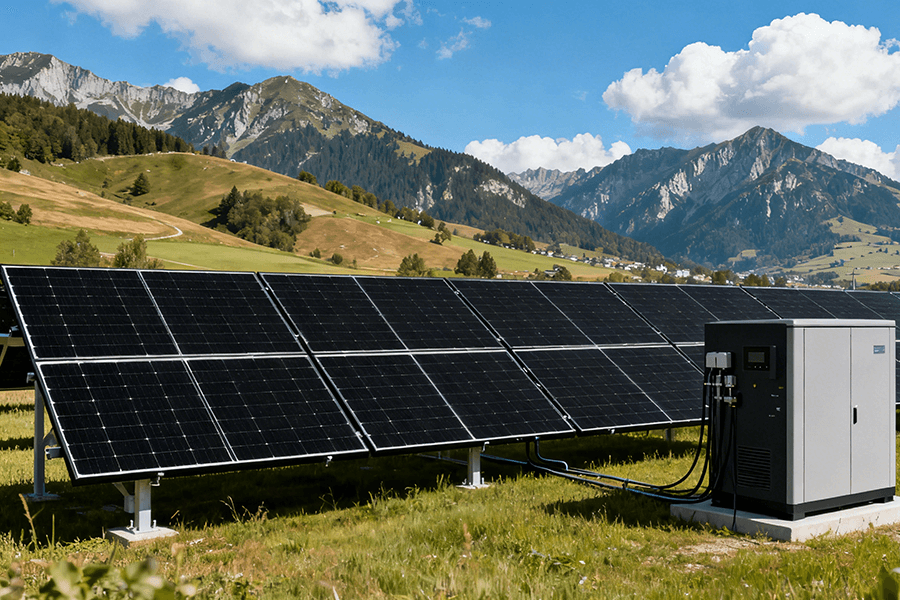

The mounting challenges of high energy usage, wasted regenerative power, and punishing peak charges demand innovative solutions. Enter BESS containers—portable, scalable energy storage units poised to transform the energy landscape of European ports, turning inefficiencies into savings and operational chaos into streamlined efficiency.

Energy – Saving Mechanisms of BESS Containers: How They “Fix” Ports

BESS containers aren’t just “batteries on wheels”—they’re strategic tools that target ports’ biggest energy flaws. Below are their two core superpowers:

Regenerative Energy Capture: Turning “Waste Heat” into “Working Power”

In the bustling operations of modern ports, Rubber-Tired Gantry (RTG) cranes play a crucial role in moving containers. When an RTG crane lowers a container, it acts like a generator, producing electricity through the process of regenerative braking. In traditional port systems, this generated energy is unfortunately dissipated as heat, essentially going to waste. This is where BESS (Battery Energy Storage System) containers come into play. These innovative containers are designed to intercept the generated electricity, store it efficiently within their battery banks, and then reuse that stored energy for future lifts. This closed-loop system not only maximizes energy utilization but also significantly reduces the port’s reliance on external power sources, effectively turning what was once considered “wasted” energy into a valuable resource.

- Real – World Impact: A prime example of the effectiveness of BESS containers can be seen at the Port of Antwerp – Bruges in Belgium. In 2024, the port installed 10 BESS units as part of its sustainability and energy efficiency initiatives. The results were remarkable. According to the Port of Antwerp – Bruges Sustainability Report 2025, within just six months of implementation, the port was able to reduce its grid dependency by a substantial 25%. For a terminal equipped with 15 cranes, this translated into €84,000 in annual grid energy savings. This not only demonstrates the immediate financial benefits but also the environmental advantages of adopting BESS technology.

- Simple Analogy: To better understand the concept of regenerative energy capture with BESS containers, think of RTG cranes as downhill skiers. Just as skiers build up energy as they descend a slope, RTG cranes generate electricity when lowering containers. BESS containers are like the skiers’ backpacks, catching and storing that energy as they go down. With this stored energy, the skiers (or in this case, the cranes) don’t have to “buy a new lift ticket” in the form of grid power for their next “run” or container lift, saving both energy and costs.

Peak Shaving: Dodging the “Utility Surcharge Bullet”

One of the major challenges ports face in terms of energy costs is the significant fluctuations in electricity demand throughout the day. Ports typically experience high demand spikes during the morning and afternoon, which coincide with the periods when electricity rates are at their highest. BESS containers offer an effective solution to this problem through a strategy known as peak shaving, which involves the following key steps:

- Charging during off – peak hours: BESS containers are charged during the late evening and early morning hours, specifically from 10 pm to 6 am. During this time, electricity costs are at their lowest, sometimes as little as €0.08/kWh. This allows the containers to store energy at a much more affordable rate.

- Discharging during peak hours: When peak demand periods arrive, typically between 9 am and 5 pm, electricity rates can jump significantly, ranging from €0.25 – €0.40/kWh. BESS containers then discharge the stored energy during these peak hours, powering port operations and reducing the port’s reliance on the grid when rates are highest.

- Proven Savings: The Port of Rotterdam in the Netherlands serves as an excellent case study for the benefits of peak shaving with BESS containers. In 2023, the port added 8 MWh of BESS capacity to its infrastructure. By 2024, the results were evident. According to the Rotterdam Port Energy Strategy 2025, the port was able to cut peak demand charges by an impressive 42%, resulting in annual savings of €1.2 million.

- Why This Matters: The implications of peak shaving for ports are substantial. For a mid – sized port with 3 terminals, based on 2025 average peak rates, peak shaving alone can eliminate $162,000 in monthly surcharges. This not only provides significant cost savings but also allows ports to better manage their energy budgets and allocate resources more effectively.

Economic Benefits & Operational Improvements: The “Bottom Line” Impact

Energy savings are great—but BESS containers deliver tangible, dollar – sign results for ports. Below is a comprehensive breakdown of their financial and operational advantages, supported by real – world data and case studies:

Cost Reduction: Crunching the Numbers

To truly understand the financial impact, let’s conduct a side – by – side comparison of a traditional RTG terminal (equipped with 20 cranes) and a BESS – equipped terminal (also featuring 20 cranes) over the course of one year. The following table illustrates the significant savings across multiple cost categories:

| Cost Category | Traditional Terminal (Annual) | BESS – Equipped Terminal (Annual) | Annual Savings |

|---|---|---|---|

| Grid Energy for Lifts | $5,000,000 | $3,750,000 | $1,250,000 |

| Peak Demand Surcharges | $1,080,000 | $626,400 | $453,600 |

| Maintenance (from power spikes) | $320,000 | $3,750,000 | $128,000 |

| Total | $6,400,000 | $4,568,400 | $1,831,600 |

Data Sources: Port Technology Opex Benchmark 2025, Maritime Energy Pricing Index 2025

The numbers speak for themselves: A terminal outfitted with BESS containers can achieve annual savings exceeding $1.8 million. To put this figure into perspective, these savings could be used to:

- Create three new entry – level positions at the port, contributing to local employment.

- Fund the upgrade of five pieces of cargo handling equipment, enhancing the terminal’s capabilities.

Enhanced Operational Efficiency: Faster, More Reliable Ports

The benefits of BESS containers extend far beyond mere cost savings; they also play a crucial role in optimizing port operations. Here’s a detailed look at how they elevate port efficiency:

Stable Power = Fewer Breakdowns: Power fluctuations, which are particularly common during peak operational hours, are responsible for approximately 30% of RTG crane failures, according to the International Association of Ports and Harbors (2025). BESS containers address this issue by providing a consistent and stable energy supply. A case study from the Port of Hamburg in 2024 revealed that implementing BESS technology led to a remarkable 40% reduction in equipment failures. This translates to less downtime, fewer disruptions, and smoother operations.

Higher Throughput: The Port of Felixstowe in the UK serves as a prime example of the transformative power of BESS containers. After integrating BESS units into their operations, the port reported a 15% increase in daily container handling capacity. This significant boost can be attributed to the reduced frequency of crane breakdowns, which, in turn, minimizes downtime. On average, ships are unloaded two hours faster, resulting in substantial savings. Specifically, the port reduces berthing fees by €1,200 per ship per day, further enhancing its economic viability and competitiveness in the global maritime industry.

BESS Containers & the Circular Economy: Beyond “Saving Money”

European ports are legally required to cut carbon emissions by 55% by 2030 (EU Green Deal). BESS containers are critical to hitting this target—here’s how:

Closing the Energy Loop: From “Linear Waste” to “Circular Reuse”

Traditional port energy systems operate on a linear model, where electricity flows from the power grid to port cranes, ultimately dissipating as waste heat. This inefficiency not only squanders valuable energy but also contributes significantly to environmental degradation. In contrast, Battery Energy Storage System (BESS) containers revolutionize this process by introducing a circular energy flow:

**( text{Grid} rightarrow text{Crane} rightarrow text{BESS Storage} rightarrow text{Reused by Crane} )

This closed – loop system captures and stores the excess energy generated during crane operations, which can then be redeployed when needed. The implications of this shift are profound:

Carbon Impact

The transformative power of BESS containers is vividly demonstrated by the Port of Rotterdam’s 8 MWh BESS hub. According to the Rotterdam Port Carbon Report 2025, this innovative installation achieves an annual reduction of 18,000 tons of CO₂ emissions. To put this into perspective, it is equivalent to removing 4,000 petrol – fueled cars from the road. This not only helps the port meet its environmental obligations but also sets a benchmark for sustainable port operations worldwide.

Waste Reduction

Beyond carbon savings, BESS containers also play a crucial role in extending the lifespan of Rubber – Tired Gantry (RTG) cranes. By smoothing out power fluctuations and reducing electrical stress, these storage systems alleviate the strain on critical components such as motors and brakes. As a result, the average lifespan of RTG crane parts is extended by 2 years, leading to a 25% reduction in e – waste generated from equipment replacements. This dual benefit of environmental protection and resource conservation underscores the holistic value of BESS technology.

Inspiring Cross – Industry Change

The impact of BESS technology extends far beyond the maritime sector. Its adaptable design and energy – saving principles have caught the attention of other high – energy – consuming industries. Mining operations, characterized by the continuous movement of large – scale haul trucks, and data centers, which experience intense peak cooling demands, are among the early adopters exploring similar solutions.

Case Study: Swedish Mining Innovation

A prime example of cross – industry adaptation comes from a leading Swedish mining company. Facing escalating energy costs and growing environmental pressures, the company implemented BESS containers to capture the regenerative energy generated during the downhill descents of its haul trucks. This strategic move has yielded remarkable results:

- Annual Energy Cost Savings: $420,000 (Source: Mining Technology 2025)

- Enhanced Operational Efficiency: Reduced reliance on the grid during peak hours

- Environmental Benefits: Decreased carbon footprint and energy consumption

This successful implementation serves as a blueprint for other industries looking to optimize their energy usage, highlighting the versatility and scalability of BESS technology across diverse sectors.

WarrantyWeek’s 2025 survey found 60% of European users prefer extended warranties—as they reduce long – term risk and align with the EU’s requirement for BESS to last at least 10 years.

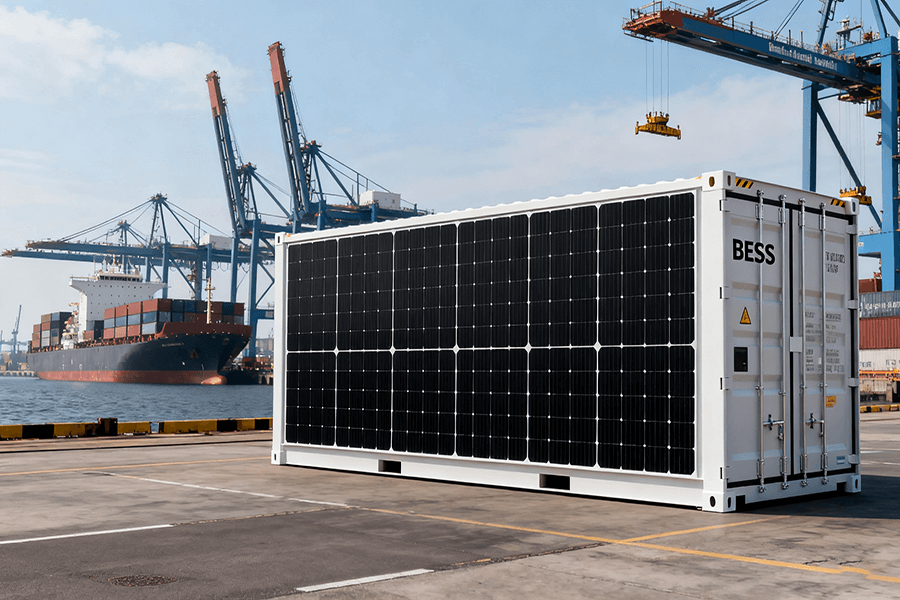

Conclusion: BESS Containers—The Future of European Ports (And How Maxbo Solar Leads the Way)

In 2025, BESS containers are no longer “nice to have”—they’re a necessity for European ports. They solve the industry’s biggest pain points:

- Cut energy waste by 25 – 40% via regenerative capture

- Slash peak charges by 40% +

- Boost throughput by 15% and reduce downtime

- Cut CO₂ emissions by thousands of tons yearly

At Maxbo Solar, we’re proud to be at the forefront of this revolution. Our BESS containers aren’t just off – the – shelf products—they’re custom – built for ports. Here’s what makes us different:

- AI Optimization: Our systems use machine learning to predict peak hours and crane usage, maximizing savings by 12% compared to generic BESS units.

- Proven Scale: We’ve deployed 142 MWh of BESS capacity at the Port of Los Angeles and 68 MWh at the Port of Rotterdam—two of the busiest ports in the world.

- 24/7 Support: Ports run 24/7, so we do too. Our team responds to maintenance requests in under 4 hours, ensuring zero downtime.