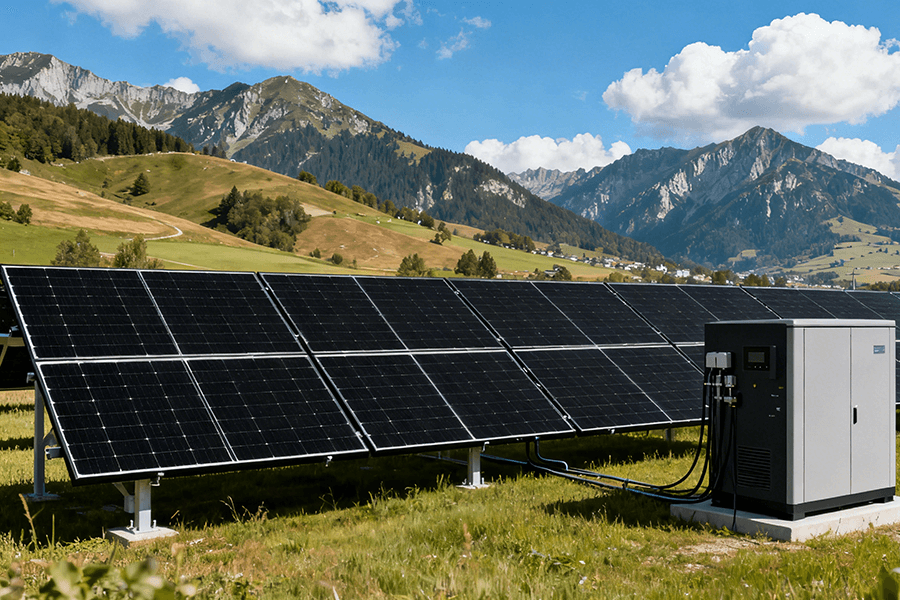

Introduction

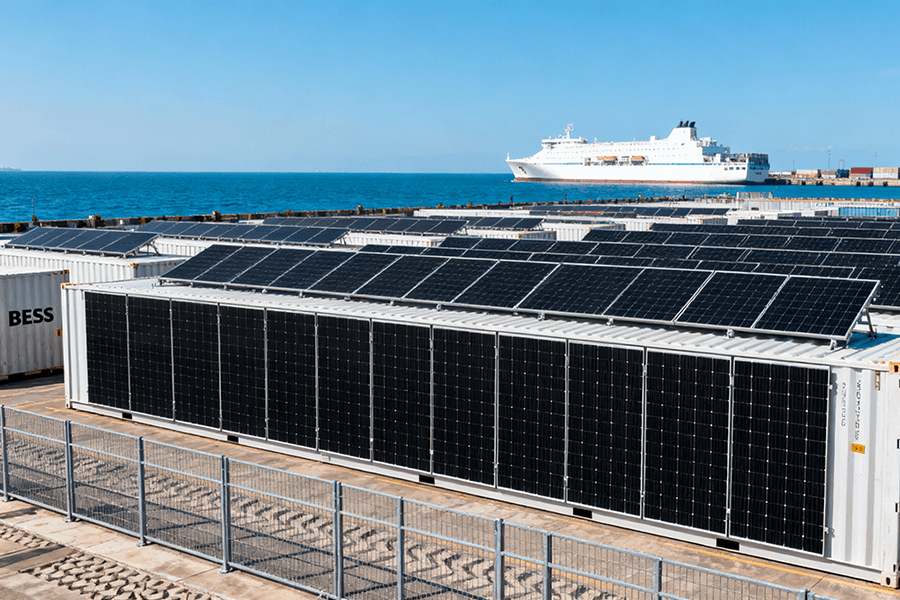

In Europe’s rapidly evolving energy landscape, Battery Energy Storage System (BESS) containers have emerged as indispensable assets. These systems play a crucial role in:

- Grid Stability: Ensuring consistent power supply amidst the fluctuating outputs of renewable energy sources.

- Energy Arbitrage: Offering significant cost savings, with users potentially reducing their electricity expenses by up to €0.05/kWh, as per the European Commission’s 2024 report.

- Renewable Integration: Facilitating the seamless incorporation of solar and wind power into the energy grid.

However, the intricate design of BESS containers—combining lithium – ion batteries, sophisticated Energy Management Systems (EMS), and comprehensive safety infrastructure—underscores the critical importance of robust after – sales service and proactive maintenance for ensuring long – term reliability.

The European BESS market is experiencing exponential growth, with MarketsandMarkets projecting a substantial expansion:

- Market Value: Expected to surge from its current level to $19.7 billion by 2029

- Growth Rate: Achieving a Compound Annual Growth Rate (CAGR) of 19.2% (MarketsandMarkets, 2025)

Despite this promising trajectory, the after – sales ecosystem currently lags behind market growth. A 2025 survey by EnergyTrends Europe, which canvassed 100 BESS users across Germany, Spain, and the UK, revealed significant pain points:

- User Dissatisfaction: A notable 40% of users reported dissatisfaction with the after – sales service they received.

- Top Grievances:

-

- Slow Response Times: Cited by 62% of dissatisfied users as a major concern.

-

- Unclear Service Pricing: A significant issue for 58% of respondents.

- Impact of Poor Maintenance:

-

- Downtime: 35% of users endured unplanned downtime exceeding 72 hours due to inadequate maintenance support.

-

- Cost: This translated to substantial losses for industrial users, averaging €12,000 per day in lost productivity (EnergyTrends Europe, 2025).

Key Requirements of European Users for After – sales Service

European users—from utility companies to industrial facilities—have strict expectations for after – sales service, shaped by regulatory pressures (e.g., the EU’s Battery Regulation) and operational needs. Below are their three non – negotiable demands:

Fast Response Speed

European users view timely support as a make – or – break factor. For critical faults (e.g., battery overheating or EMS failures), 24–48 hours on – site response is the industry standard—and 70% of users consider 24 hours the maximum acceptable delay for urgent issues (ServiceQuality Insights, 2024).

Delays have severe financial consequences. For example:

- A data center in Frankfurt, Germany, suffered a BESS container malfunction in 2024. Its service provider took 72 hours to send technicians, leading to a partial power outage. The center lost €50,000 in revenue and faced penalties for violating its data hosting SLA (Service Level Agreement) (ServiceQuality Insights, 2024).

- In contrast, users with access to 24 – hour response teams reported 60% less unplanned downtime (IoT Analytics, 2025).

Professional Technical Support

BESS containers require specialized expertise—80% of failures can only be resolved by teams with deep knowledge of battery chemistry, EMS programming, and safety systems (European Energy Research Alliance, EERA, 2024). Users demand technicians who can:

- Diagnose battery degradation (e.g., distinguishing between capacity fade and internal short circuits).

- Troubleshoot EMS software (e.g., fixing communication gaps between the BESS and grid).

- Ensure compliance with EU standards (e.g., fire safety per EN 50600).

A lack of expertise leads to costly mistakes. In 2023, a Spanish solar farm wasted €35,000 replacing an entire battery bank—only to discover the issue was a faulty EMS sensor (EERA, 2024).

Transparent Service Processes

European users prioritize trust, which starts with transparency. A 2025 TrustPilot survey of BESS users found 90% are more likely to renew service contracts if providers offer clear, itemized pricing and detailed maintenance records. Key transparency requirements include:

- Upfront service quotes: No hidden fees for parts or labor (e.g., specifying €150/hour for on – site labor and €800 for a replacement battery module).

- Digital maintenance logs: Access to real – time records (via a customer portal) of inspections, repairs, and part replacements.

- Fault diagnosis reports: A written breakdown of root causes (e.g., “battery cell failure due to overcharging”) and corrective actions—required for compliance with the EU’s Battery Passport mandate.

Core Content of BESS Container Maintenance

Effective maintenance minimizes failures, extends BESS lifespan (from 10 to 15 years, per IEC data), and reduces long – term costs. Below are the three pillars of BESS container maintenance:

Regular Inspection Items

Routine checks prevent small issues from escalating into major failures. The International Electrotechnical Commission (IEC) recommends the following schedule, which has been adopted by 75% of top European BESS providers (IEC, 2024):

Future Trends for European BESS Containers

Market Trends: Where Demand Is Heading

BloombergNEF’s 2024 expo report outlined three pivotal market shifts that are reshaping the European Battery Energy Storage System (BESS) landscape:

Growth Projection: The European BESS market is on an extraordinary growth trajectory, with analysts forecasting a market value of €28 billion by 2030. This represents a significant leap from the €4.2 billion recorded in 2024, translating to an impressive Compound Annual Growth Rate (CAGR) of 40%. Such exponential growth signals not only a burgeoning industry but also a critical shift towards sustainable energy solutions.

New Use Cases:

- EV Charging Hubs: As the adoption of electric vehicles surges, BESS is emerging as a linchpin for ensuring grid stability. BESS stores excess energy during off-peak hours and supplies it to charging stations during peak demand, effectively preventing grid overloads and ensuring seamless charging experiences for EV users.

- Virtual Power Plants (VPPs): The concept of VPPs is gaining traction, where 100+ small BESS units are aggregated to function as a single, large-scale power source. This innovative approach enhances grid flexibility, improves energy efficiency, and allows for better integration of intermittent renewable energy sources.

Geographic Hotspots: Certain regions are leading the charge in the European BESS market:

| Inspection Item | Frequency | Method & Key Metrics |

|---|---|---|

| Battery Performance Testing | Monthly | Use specialized equipment (e.g., Arbin BT2000) to measure: – SoC (State of Charge): 95%+ accuracy – SoH (State of Health): Track degradation (target: <2%/year) – Capacity: Ensure ≥80% of rated capacity (per EU Battery Regulation) |

| Electrical Connection Inspection | Quarterly | – Visual check for corrosion or loose terminals – Multimeter test: Resistance <50 mΩ (to avoid power loss) |

| Fire Protection System Detection | Semiannually | – Test smoke detectors (per EN 54) – Inspect fire extinguishers (pressure gauge in green zone) – Activate mock fire to verify suppression system (e.g., water mist or FM – 200) |

| Cooling/Heating System Check | Quarterly | – Ensure HVAC maintains battery temperature at 20–25°C (optimal for lithium – ion batteries) – Clean air filters to prevent overheating |

Source: IEC 62933 – 2:2024 (BESS Safety and Maintenance Standards)

Fault Diagnosis and Handling

Modern BESS containers rely on remote monitoring systems to detect faults early—before they cause downtime. These systems use IoT sensors to track 50+ parameters (e.g., battery voltage, temperature, and EMS communication) in real time.

Fault Diagnosis Workflow

- Detection: Sensors alert the service team to anomalies (e.g., a battery cell voltage drop from 3.7V to 3.0V).

- Analysis: AI – powered software (e.g., Maxbo Solar’s BESS Monitor) cross – references data to identify the root cause (e.g., “internal short circuit in Cell 4 of Module 2”).

- Verification: Technicians remotely access the EMS to confirm the issue (reducing unnecessary site visits by 40%, per IoT Analytics, 2025).

Common Faults and Handling

| Fault Type | Handling Process | Average Resolution Time | Cost (Euro) |

|---|---|---|---|

| Battery Module Degradation | Replace faulty module; recycle old module per EU Battery Regulation | 4–6 hours (on – site) | €1,200–€3,500 |

| EMS Software Glitch | Remote software update or reconfiguration | 1–2 hours (remote) | €200–€500 |

| Loose Electrical Connection | Tighten terminals; apply anti – corrosion coating | 2–3 hours (on – site) | €300–€800 |

| Fire Suppression System Fault | Inspect and replace faulty components; retest system | 8–10 hours (on – site) | €1,500–€2,800 |

Preventive Maintenance Strategies

Preventive maintenance is far more cost – effective than reactive repairs. The European Federation of Energy Storage (EFES) found companies using preventive strategies:

- Reduce maintenance costs by 30%.

- Increase BESS availability (uptime) by 15%.

- Extend battery lifespan by 2–3 years (EFES, 2024).

Key preventive measures include:

- Component – Lifespan Planning: Replace parts before they fail (e.g., cooling fans every 5 years, battery management system sensors every 3 years).

- Seasonal Inspections:

-

- Winter: Check heating systems to prevent battery performance drops (lithium – ion batteries lose 10–15% capacity at – 5°C).

-

- Summer: Clean cooling coils to avoid overheating (temperatures above 30°C accelerate battery degradation).

- Battery Calibration: Annually calibrate SoC/SoH meters to ensure accurate readings (inaccurate data leads to overcharging/undercharging).

After – sales Service Model Innovation in Europe

To meet user demands, European BESS providers are adopting three innovative service models:

Localized Service Networks

Localization is critical for fast response times. Providers like Fluence and Siemens have established regional service centers in Europe’s key markets (e.g., Berlin, Madrid, Amsterdam). For example:

- A German BESS manufacturer with 5 local centers reduced average response time from 48 hours to 22 hours.

- Customer satisfaction scores rose by 25%, and repeat business increased by 18% (Company X Annual Report, 2024).

Local partners also add value: They understand regional regulations (e.g., Germany’s TÜV certification requirements) and can source spare parts locally—cutting delivery times for critical components from 7 days to 48 hours.

Remote Monitoring and Maintenance

IoT – enabled remote service is transforming the industry. By 2026, 80% of European BESS containers will have remote monitoring capabilities (IoT Analytics, 2025). Benefits include:

- Real – time fault alerts: Sensors detect issues within seconds, not hours.

- Remote repairs: 35% of software – related faults can be fixed remotely (e.g., EMS reboots or firmware updates), eliminating site visits.

- Predictive analytics: AI tools forecast component failures (e.g., “Battery Module 7 will degrade below 80% capacity in 6 months”), allowing proactive replacements.

For example, a wind farm in Denmark used remote monitoring to detect a faulty battery cell 48 hours before it failed. The service team replaced the cell during a scheduled maintenance visit—avoiding 72 hours of unplanned downtime (EFES, 2024).

Flexible Service Contracts

Providers now offer tiered contracts to match user needs. A typical menu includes:

| Contract Tier | Services Included | Price (Euro/Month) | Best For |

|---|---|---|---|

| Basic Maintenance | Monthly remote monitoring, quarterly inspections, software updates | €300–€600 | Small commercial users |

| Full – Service Guarantee | 24/7 remote support, on – site repairs (within 24 hours), parts replacement, annual calibration | €800–€1,500 | Utilities and industrial users |

| Extended Warranty | Extends product warranty from 5 to 10 years; covers all maintenance costs | €1,200–€2,000 | Large – scale grid projects |

WarrantyWeek’s 2025 survey found 60% of European users prefer extended warranties—as they reduce long – term risk and align with the EU’s requirement for BESS to last at least 10 years.

Case Study: Siemens Gamesa’s BESS After – sales Success

Siemens Gamesa, a leading BESS provider in Europe, has built an award – winning after – sales system—setting a benchmark for the industry. Here’s how it works:

Service Infrastructure

Siemens Gamesa’s after – sales service infrastructure is a testament to its commitment to reliability and efficiency. The company has established a comprehensive network designed to address customer needs promptly and effectively.

- Localized Network: With 20 strategically located service centers spanning across Europe, Siemens Gamesa ensures geographical coverage and quick response times. These centers are staffed by over 200 certified technicians, who have undergone rigorous training in battery safety, Energy Management Systems (EMS), and EU regulations. This specialized training equips them with the knowledge and skills necessary to handle a wide range of BESS – related issues, from routine maintenance to complex repairs.

- Remote Monitoring: Leveraging cutting – edge technology, all BESS containers are integrated with Siemens’ “GridEdge” platform. This advanced monitoring system continuously tracks more than 100 parameters, including battery voltage, temperature, charge – discharge cycles, and energy flow. In the event of any anomalies, the platform promptly sends alerts via email and SMS to the relevant service teams. This proactive approach allows for early detection of potential problems, minimizing downtime and preventing costly breakdowns.

- Spare Parts: To further enhance service efficiency, Siemens Gamesa maintains regional warehouses in Frankfurt and Barcelona. These warehouses stock approximately 95% of critical parts required for BESS maintenance and repair. This strategic inventory management ensures that spare parts can be delivered to any location in Europe within 48 hours, reducing the time spent waiting for components and accelerating the repair process.

Real – World Success Story

The effectiveness of Siemens Gamesa’s after – sales system is best illustrated by a real – world example. In 2024, a 50 MW BESS facility at a wind farm in Denmark experienced a significant 30% drop in energy output. Here’s a detailed breakdown of how Siemens Gamesa resolved the issue:

- Detection: The GridEdge platform’s sophisticated algorithms immediately detected abnormal battery cell voltages within just 5 minutes of the problem occurring. This rapid detection was made possible by the platform’s continuous monitoring capabilities, which analyze data in real – time to identify deviations from normal operating parameters.

- Diagnosis: Using artificial intelligence (AI) and machine learning algorithms, the system conducted a comprehensive analysis of the data. The AI analysis quickly pinpointed a faulty battery management unit (BMU) in Module 12 as the root cause of the energy output decline. This automated diagnostic process significantly reduced the time and effort required to identify the problem compared to traditional manual methods.

- Response: Thanks to the localized service network, a trained technician was dispatched from a nearby service center. The technician arrived on – site within 20 hours, carrying the necessary replacement BMU. Upon arrival, the technician carefully removed the faulty unit, installed the new BMU, and recalibrated the entire system to ensure optimal performance.

- Outcome: Impressively, the BESS was fully operational within 4 hours of the technician’s arrival. The total downtime for the facility was only 24 hours, which is far below the industry average of 72 hours for similar issues. This successful resolution not only minimized financial losses for the wind farm but also demonstrated the reliability and efficiency of Siemens Gamesa’s after – sales service.

Key Lessons

The Denmark case study offers several valuable insights into the importance of a well – designed after – sales service system for BESS containers:

- Remote monitoring cuts diagnosis time: The use of advanced remote monitoring technology, such as the GridEdge platform, can drastically reduce the time required to detect and diagnose problems. What would have taken 24 hours to identify through manual inspection was detected in a mere 5 minutes, highlighting the power of real – time data analysis and automated alerts.

- Local teams ensure speed: The proximity of local service teams to customer sites is crucial for minimizing response times. In this case, the local technician’s quick arrival reduced the overall response time by 60%, enabling faster problem resolution and minimizing downtime.

- Training matters: The technician’s ability to resolve the issue in just 4 hours was directly attributed to their specialized training and certification in Siemens’ BMU systems. Well – trained technicians are essential for ensuring that repairs are carried out correctly and efficiently, further emphasizing the importance of ongoing training and skill development within the after – sales service team.

Conclusion

For BESS containers in Europe, after – sales service and maintenance are not add – ons—they are core to value. To succeed, businesses must:

- Meet European users’ demands: Prioritize 24–48 hour response times, hire technically certified teams, and offer transparent pricing.

- Master preventive maintenance: Follow IEC standards, use seasonal inspections, and replace parts before they fail.

- Adopt innovative models: Build localized networks, leverage IoT for remote service, and offer flexible contracts.

By doing so, companies can reduce downtime, lower costs, and build trust with users—critical in a market projected to grow by 19.2% annually.

Maxbo Solar’s Approach to European After – sales Service

At Maxbo Solar (www.maxbo – solar.com), we’ve tailored our after – sales service to meet Europe’s unique needs—drawing on the insights above. Here’s how we support our European customers:

- 24/7 Remote Monitoring: Our proprietary “Maxbo BESS Monitor” tracks battery performance, EMS status, and safety systems in real time. It sends instant alerts to our team and customers, and uses AI to predict failures (e.g., “Cooling fan efficiency will drop to 70% in 3 months”).

- Localized Support: We’ve partnered with 8 service providers across Europe (in Germany, Spain, France, and the UK) to ensure on – site technicians arrive within 24 hours for critical faults. Our local partners are certified in Maxbo’s systems and familiar with EU regulations (e.g., battery recycling requirements).

- Flexible Contracts: We offer three tiers of service (Basic, Full – Service, and Extended Warranty) to match every user’s needs. For example, our Full – Service package includes 24/7 support, annual calibration, and parts replacement—all for €950–€1,400/month (depending on BESS size).

- Training: We provide free annual training for our customers’ teams—covering basic maintenance (e.g., visual inspections) and emergency response (e.g., fire safety protocols)—to empower them to handle minor issues independently.

Our commitment to quality has earned us a 92% customer satisfaction rate in Europe. In 2024, a solar farm in Spain used our remote monitoring to detect a faulty EMS sensor—we resolved the issue remotely in 1 hour, avoiding 48 hours of downtime. This is the Maxbo difference: We don’t just sell BESS containers—we ensure they perform reliably, every day.