The Clock is Ticking: Why Europe’s Ports Can’t Afford Diesel Anymore

Picture a European port just a decade ago: diesel generators hummed like irritable bees around the clock, belching black fumes while powering everything from massive ship-to-shore cranes to temperature-controlled refrigerated containers. Fast forward to 2025, and the EU is holding up a very loud stopwatch.

The “Fit for 55” package isn’t a gentle nudge toward sustainability—it’s a legally binding mandate that delivers a clear beatdown for high-emission maritime operations. Key requirements include a 2% cut in shipping fuel greenhouse gas intensity by 2025 and a staggering 80% reduction by 2050 Link. For port operators, the old “diesel-first” mindset is no longer just environmentally reckless—it’s a direct threat to business viability.

The numbers paint a grim (and expensive) picture of pre-BESS port operations. Below is a breakdown of the core pain points that had port managers reaching for the antacids—and why BESS emerged as the perfect antidote:

|

Pain Point

|

Scale of the Problem

|

Direct Business Impact

|

|---|---|---|

|

Greenhouse Gas Emissions

|

EU ports account for ~3% of the entire maritime sector’s emissions Link

|

Risk of non-compliance fines (up to €10,000/day for major ports) and reputational damage

|

|

Diesel Cost Volatility

|

Eurostat data shows 2024 Q4 diesel prices up 12% year-over-year Link

|

Unpredictable operational expenses (OPEX); frequent budget overruns; reduced profit margins

|

|

Grid Instability

|

Refrigerated containers (reefers) can spike power demand to 25MW—equivalent to 20,000 households Link

|

Steep grid surcharges; risk of power outages that disrupt cargo handling and trigger penalties

|

|

Maintenance Headaches

|

Diesel gensets require servicing every 500-800 operating hours

|

Costly downtime; rising labor expenses; unplanned repair bills

|

In short, diesel was the port equivalent of a gas-guzzling 1970s sedan—reliable enough to get the job done in a pinch, but costing a fortune in repairs, fuel, and parking tickets. BESS containers, by contrast, are the sleek electric hybrid: quiet, cheap to run, and fully compliant with the EU’s strict emissions rules.

BESS Containers at Work: The Two Superpowers Transforming Ports

Let’s dispel a common myth: BESS containers aren’t just “big batteries.” They’re sophisticated energy management systems—think of them as the port’s “energy bartender.” They stock up on cheap drinks (electricity) during quiet hours, serve them up quickly when the crowd (peak demand) arrives, and even recycle leftover ice (waste energy) to make more drinks. Their value stems from two core superpowers, both tailored to solve port-specific challenges.

Shore Power Integration: Beat the Grid Peak, Keep the Reefers Cold

Refrigerated containers—affectionately called “reefers”—are the port’s biggest energy hogs. A single 40-foot reefer uses roughly 4kW of power, and a busy terminal with 5,000 reefers can hit a jaw-dropping 25MW peak demand. Before BESS, ports had two bad options: fire up expensive diesel generators or pay exorbitant peak-time grid charges.

BESS changes the game by playing the “buy low, sell high” game with electricity—a strategy called peak shaving that directly targets the reefer problem. Here’s how it works in practice, using Rotterdam’s 20MWh BESS project as a model:

The BESS Peak-Shaving Playbook (Proven at Rotterdam Port):

-

Off-Peak (2 AM – 6 AM): Charge the BESS using cheap, renewable grid power (often 30-40% less expensive than peak rates—€0.12/kWh vs. €0.20/kWh).

-

Peak (10 AM – 3 PM): Discharge stored energy to power reefers and cranes, avoiding grid surcharges that can add €0.15/kWh to electricity costs.

-

Result: Rotterdam’s 20MWh BESS cuts peak grid draw by 60%, eliminating 11,000 diesel generator operating hours yearly Link.

Energy Recycling: Turn Crane Brakes into Cold Hard Cash

Ever watched a massive port crane lower a 20-ton shipping container? That’s not just brute force—it’s wasted energy. Port cranes, straddle carriers, and forklifts generate regenerative energy whenever they brake or lower heavy loads. Before BESS, this energy was simply lost as heat (literally just warming up the tarmac on hot days).

Now, BESS containers act like high-tech energy catchers. They capture this regenerative power, store it efficiently, and feed it back into the port’s electrical system for immediate use. It’s like finding a way to reuse the heat from your oven to cook a second meal—brilliant, and totally free.

The math here is too good to ignore. Let’s break down the tangible gains from energy recycling, using Antwerp’s 15MWh BESS project as a case study:

-

A single rubber-tired gantry crane (RTG) generates ~150kWh of regenerative energy per 8-hour shift.

-

A terminal with 20 RTGs produces 3,000kWh of free energy daily—enough to power 750 reefers for 4 hours.

-

Antwerp’s BESS system recycles 12% of the port’s total energy use this way, cutting fuel needs by 9% and avoiding 5,200 tons of CO₂ annually Link.

The Double Win: Green Cred + a Fat Wallet

The best part about BESS containers? They don’t force ports to choose between environmental responsibility and profitability. It’s a genuine “have your cake and eat it too” scenario—minus the sugar crash. To prove this, we’ve compiled hard data from two of Europe’s most successful BESS port projects:

|

Port Project

|

BESS Capacity

|

Environmental Impact

|

Economic Impact

|

Source

|

|---|---|---|---|---|

|

Rotterdam Port (Container Terminal 4)

|

20MWh (10MW power output)

|

8,400 tons CO₂ saved/year (equivalent to removing 1,800 passenger cars) Link

|

€2.3M in annual diesel cost savings; €500k in grid surcharge reductions

|

Port of Rotterdam Sustainability Dashboard 2025 Link

|

|

Antwerp Bruges Terminal (E12)

|

15MWh (7.5MW power output)

|

5,200 tons CO₂ saved/year (equivalent to 1,130 passenger cars)

|

€2.3M in annual fuel cost savings; €400k in grid surcharge savings

|

Antwerp Port Authority 2025 Report Link

|

To put these numbers in perspective: 8,400 tons of CO₂ is the same as burning 920,000 liters of diesel—or if 42,000 people each drove 1,000 km in a standard gasoline car. And €2.3M in annual savings? That’s enough to hire 30 additional dock workers, upgrade cargo tracking technology, or invest in further sustainability projects.

BESS isn’t just a “green investment”—it’s a smart business investment that delivers returns from day one. Port operators no longer have to choose between doing good and doing well; BESS makes both possible.

2025 Breakthrough: Greece’s 10MW BESS Powers Ferries with 100% Renewables

If Rotterdam and Antwerp are BESS “early adopters,” Greece’s 2025 port project is the clear “game-changer.” Located in the bustling port of Thessaloniki—Greece’s second-largest city and a key Mediterranean hub—this 10MW BESS system isn’t just powering cranes or reefers. It’s fueling passenger ferries with 100% renewable energy.

That’s right: no diesel, no fumes, just clean solar and wind power stored in a handful of standard shipping containers. This isn’t just ahead of the curve—it’s rewriting the rulebook for maritime electrification.

Here’s why this matters: Ferries are the maritime industry’s “dirty secret.” A single large passenger ferry emits as much CO₂ per year as 10,000 passenger cars Link. The EU’s FuelEU Maritime regulation will require ferries to use shore power when berthed by 2030 Link, but Greece is beating that deadline by a full 5 years.

The Thessaloniki project’s specs read like a BESS resume—impressive, practical, and results-driven:

-

Capacity: 10MW power output, 20MWh storage (enough to charge 2 medium-sized ferries simultaneously)

-

Energy Source: Directly tied to a 50MW solar farm and 30MW wind park nearby—guaranteeing 100% renewable input

-

Charging Speed: 30-minute fast charge for ferries (perfectly matches standard passenger boarding time, no operational delays)

-

Cost Savings: €1.8M/year in diesel costs for ferry operators; €300k/year in port energy expenses

-

Emissions Cut: 6,700 tons CO₂ saved annually (equivalent to 1,450 passenger cars taken off the road)

The project’s success stems from its seamless integration with Greece’s rapidly growing renewable energy network. In 2025 alone, Greece’s renewable energy “curtailment” (energy that’s generated but can’t be used by the grid) hit 601 GWh in summer—enough to power 170,000 households for a year Link.

The Thessaloniki BESS soaks up this excess green power and turns it into usable ferry fuel, solving two critical problems at once: reducing renewable energy waste and slashing maritime emissions. It’s like turning leftover lemonade into a five-star cocktail—resourceful, profitable, and infinitely better for the taste buds (or in this case, the planet).

The Future: Every European Port Will Have a BESS—Here’s Why We’re Leading the Charge

By 2030, BESS containers won’t be a “nice-to-have” for European ports—they’ll be as essential as cranes and dock workers. The EU’s “Fit for 55” targets, rising diesel prices (projected to increase 15% by 2027 Link), and the growing demand for electric ferries and shore power all point to one inevitable conclusion: BESS is the future of port energy.

Industry forecasts back this up. The European port BESS market is expected to grow at a compound annual rate (CAGR) of 28% through 2030, hitting a total value of €2.1B Link. But here’s the critical caveat: not all BESS containers are built to survive the harsh realities of port life.

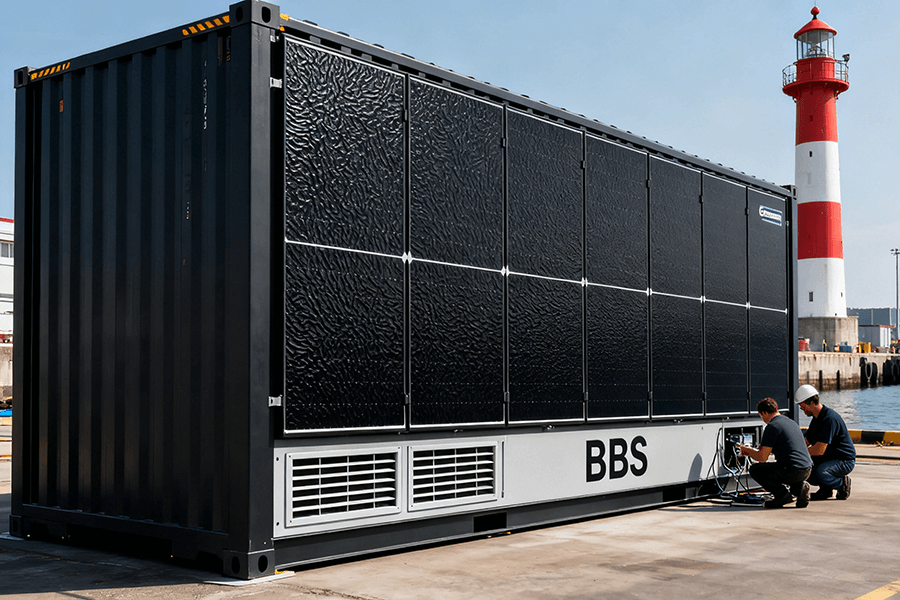

Maritime environments are brutal: saltwater corrosion, high winds, constant vibration, and extreme temperature swings can turn a standard BESS into a very expensive paperweight. That’s where Maxbo Solar comes in. And yes, that’s us—I’m part of the engineering team that’s been designing and building maritime-specific BESS solutions since 2018.

We don’t just slap a battery pack in a steel container and call it “port-ready.” Our systems are engineered from the ground up to thrive in the harshest coastal conditions. We understand that port operators need reliability above all else—so we build BESS that works as hard as they do.

Here’s what makes Maxbo Solar’s port BESS solutions stand out from the crowd:

Maritime-Grade Durability

We use saltwater-resistant enclosures, IP67-rated electrical components, and vibration-dampening frames to protect the battery cells. Our BESS can handle everything from North Sea storms to Mediterranean heatwaves—no performance drops, no unexpected failures.

AI-Powered Smart Integration

Our proprietary energy management system (EMS) uses machine learning to automatically shift between grid power, renewables, and storage. It predicts peak demand, optimizes charging times, and requires zero human intervention—saving your team time and hassle.

Fast Deployment & Support

We deliver pre-assembled, plug-and-play BESS containers that are fully operational in just 2 weeks—no 6-month construction delays. Plus, our 24/7 technical support team is always on call to keep your system running.

We’re not just selling batteries—we’re selling peace of mind. We were proud to partner on Rotterdam’s 20MWh BESS project, helping them achieve those 8,400 tons of annual CO₂ savings. And we’re currently working with Greek port authorities to scale their ferry electrification efforts beyond Thessaloniki.

Our goal is simple: to make diesel generators in European ports as rare as a payphone on a modern street corner. We believe that sustainability and profitability go hand in hand—and our BESS systems prove it every single day.