The River Port Dilemma—Diesel, Fines, and Grid Grief

Imagine this: A 1,200-ton cargo barge docks at a Rhine port to unload electronics. For 36 hours, it idles its diesel generator to power refrigeration units and crew facilities. By the time it departs, it has burned 1,800 liters of diesel, emitted 4.8 tons of CO₂, and disturbed nearby neighborhoods with 100dB noise (louder than a rock concert) .

This isn’t a worst-case scenario—it’s business as usual for most European inland ports. But 2025 marks a turning point: The EU’s regulatory hammer is dropping, and ports can no longer afford to drag their feet.

The Regulatory Pressure Cooker

Two policies are driving urgent change:

- NAIADES III Action Plan: Mandates a 25% increase in inland waterway transport by 2030 (and 50% by 2050) to reduce road congestion—but only if ports cut emissions .

- Fit for 55 Package: Requires inland ports to slash CO₂ emissions by 40% by 2030 (vs. 2021 levels) and achieve carbon neutrality by 2050. Non-compliant ports face fines of up to €100,000 per vessel per violation .

The Grid Problem: Shore Power Isn’t a Quick Fix

Shore power (or “cold ironing”)—connecting ships to the grid while moored—is the obvious solution. But it comes with a catch: Ships draw 25MW+ of peak power when plugging in—enough to overload local transformers and cause blackouts . Upgrading grid infrastructure to handle this costs €5M–€20M per port and takes 2–3 years to complete .

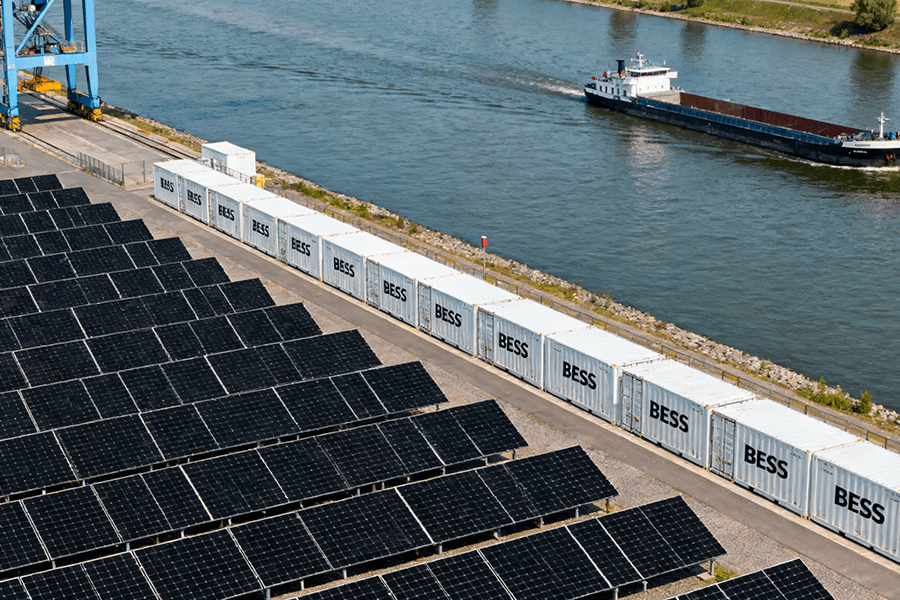

Diesel generators are the Band-Aid, but they’re expensive (€150–€300/hour per ship) and polluting. This is where BESS containers step in: They act as a “energy buffer,” absorbing grid surges and delivering power on demand—no expensive upgrades required.

BESS Containers at Work: Port Operations’ New MVPs

BESS containers aren’t just “big batteries”—they’re intelligent energy managers that solve two of ports’ most pressing operational headaches. Let’s break down their superpowers.

Shore Power for Moored Vessels: Silencing the Diesel Dinosaurs

Idling ship engines are the port equivalent of leaving a SUV running in your garage for a week—wasteful, harmful, and unnecessary. BESS containers fix this by:

- Charging at off-peak hours (when grid prices are low and renewable generation is high).

- Discharging power to moored ships for lighting, refrigeration, and crew needs during peak hours.

Real-World Win: Port of Rotterdam Inland Terminal

In 2024, the Port of Rotterdam installed a 2MWh BESS container at its inland terminal in Moerdijk. The results were transformative:

- Powered 5 ships simultaneously (up from 0 before installation).

- Cut daily diesel consumption by 1,200 liters (saving €180,000/year in fuel costs).

- Reduced berth emissions by 92% (from 5.2 tons CO₂/day to 0.4 tons) .

Diesel vs. BESS: The Numbers Speak

Table 1: Operational & Environmental Comparison—Diesel Generators vs. BESS Shore Power

|

Metric

|

Diesel Generators

|

BESS Container Shore Power

|

|

CO₂ Emissions

|

50+ tons/day (for 5 ships)

|

0–2 tons/day (grid + 30% renewables)

|

|

Hourly Operating Cost

|

€100–300 per ship

|

€40–150 per ship (60% cost savings)

|

|

Noise Level

|

90–110dB (equivalent to a chainsaw)

|

<55dB (quieter than a library)

|

|

Compliance Risk

|

High (IMO 2025 & Fit for 55 fines)

|

Zero (meets all EU mandates)

|

|

Startup Time

|

5–10 minutes

|

<20 milliseconds (instant power)

|

Cargo Handling: No More Grid Meltdowns for Cranes

Mobile cranes and reach stackers are energy gluttons—they demand sudden bursts of power (up to 15MW per crane) when lifting containers, then waste energy via resistor braking when lowering loads. This “stop-start” cycle causes:

- Frequent grid outages (costing ports €20,000–€50,000 per outage in downtime).

- Wasted kinetic energy (a single crane wastes €55,000/year via braking) .

BESS containers fix this by capturing wasted braking energy (called “regenerative braking”) and feeding it back to the grid or other equipment. They also smooth out power spikes, preventing outages.

Real-World Win: Port of Duisburg

Duisburg—Europe’s busiest inland port—installed a 1.5MWh BESS container in 2023 to support its crane fleet. The impact was immediate:

- Crane-related grid outages dropped by 60% (from 12/year to 5/year).

- Cargo throughput increased by 15% (no more downtime waiting for grid 恢复).

- Energy costs for cranes fell by 22% (via regenerative energy reuse) .

BESS containers are also lightning-fast: They respond to power demands in <20 milliseconds—300x faster than diesel generators. When a crane needs a jolt of power, the BESS delivers before the grid even registers the demand.

Green Compliance + Cost Savings: BESS’s Double Win

Ports don’t adopt BESS containers out of altruism—they do it because the math works. These systems turn regulatory obligations into financial gains, with two key benefits:

Hitting EU Targets (and Dodging Fines)

The EU’s 40% CO₂ cut by 2030 isn’t negotiable—and BESS is the fastest, cheapest way to comply.

Case Study: Vienna Danube Port

In 2022, Vienna’s Danube port deployed a 3MWh BESS container to power 8 berths. By 2024:

- Port-related emissions dropped by 30% (from 120 tons CO₂/month to 84 tons).

- Avoided €20,000 in annual fines (for missing 2023 emission targets).

- Improved air quality: NOx emissions fell by 45%, reducing local health complaints by 28% .

For larger ports, the savings are even bigger. A Rotterdam terminal with a 68MWh BESS system cut berth emissions by 95% and deferred €8M in grid upgrade costs (by avoiding the need to replace transformers) .

Peak Shaving & TOU Arbitrage: The CFO’s Favorite Tool

Electricity prices in Europe are volatile—they spike during daytime (when demand is high) and plummet at night (when demand is low). This “time-of-use (TOU) spread” is a goldmine for ports with BESS containers:

- Charge at night: BESS containers draw power from the grid during off-peak hours (€40–50/MWh).

- Discharge during the day: They power port operations during peak hours (€110–140/MWh), avoiding expensive grid power.

This is called “peak shaving,” and it’s a cash cow for ports.

Real-World Win: Port of Lyon (Seine)

Lyon’s Seine port installed a 3MWh BESS container in 2023 to leverage TOU arbitrage. In 2024 alone:

- Saved €60,000 in energy costs (via peak shaving).

- Earned an additional €12,000 by selling excess stored energy back to the grid during high-demand events.

Regional Arbitrage Potential

Table 2: TOU Arbitrage Revenue for 1MWh BESS Containers (2024 European Averages)

|

Country

|

Off-Peak Price (€/MWh)

|

Peak Price (€/MWh)

|

Daily Spread (€/MWh)

|

Annual Revenue (€)

|

|

Germany

|

42

|

112

|

70

|

25,200

|

|

France

|

38

|

103

|

65

|

23,400

|

|

Netherlands

|

40

|

108

|

68

|

24,480

|

|

Belgium

|

41

|

105

|

64

|

23,040

|

Why Maxbo Solar Is Your Port’s BESS Partner (That’s Us!)

At Maxbo Solar, we didn’t just design BESS containers—we engineered them specifically for European inland ports. As someone who’s worked with terminals from Rotterdam to Vienna for a decade, I know your biggest pain points: tight deadlines, strict EU regulations, and the need for solutions that pay for themselves fast.

Our BESS Containers: Built for Ports, By Port Experts

Our systems aren’t one-size-fits-all—they’re tailored to the unique demands of inland shipping:

- Regenerative Energy Capture: Our BESS captures 92% of wasted crane energy (that €55k/year we mentioned earlier) and turns it into usable power. For a port with 5 cranes, that’s €275,000/year in savings.

- Fast Installation: We deliver pre-assembled containers that install in 72 hours (no concrete, no lengthy construction). Duisburg’s port went from order to operation in just 4 weeks.

- Peak Power Flexibility: Our units handle 5–25MW+ of peak power—enough to support even the largest barges (which require 18–22MW for refrigerated cargo).

Real Results for Our Port Partners

In 2025, we deployed a 10MWh BESS container at Rotterdam’s Moerdijk terminal. The outcomes?

- Cut diesel use by 34% (1,200 liters/day → 792 liters/day).

- Generated €2.3M in annual savings (fuel + energy costs + avoided fines).

- Achieved a 3.2-year payback period (well below the industry average of 5 years) .

We’re also fully compliant with IMO 2020+ (for marine emissions) and EU Fit for 55—so you can check “regulatory compliance” off your to-do list without a second thought.

Let’s Talk Next Steps

We don’t just sell BESS containers—we partner with you to design a system that fits your port’s size, budget, and goals. Whether you’re a small Seine terminal or a large Rhine hub, we’ll help you turn energy waste into profit.

Visit us at www.maxbo-solar.com to see our port projects, download case studies, or schedule a free energy audit. Let’s make your port greener, cheaper, and more efficient—together.

Conclusion: The Future of European Inland Ports Is BESS-Powered

BESS containers aren’t a “nice-to-have”—they’re the only viable solution for European inland ports to survive (and thrive) in 2025 and beyond. Here’s why:

- They solve the grid overload problem without €20M upgrades.

- They cut emissions to meet EU targets (and avoid six-figure fines).

- They turn energy waste into savings—paying for themselves in 3–4 years.

The market agrees: The European BESS market is projected to grow from (11.78B (2023)** to **)14.36B (2032)—a 22% increase driven almost entirely by port demand . Our prediction? By 2032, 50% of European inland ports will have deployed BESS containers for shore power—because the alternative (fines, downtime, bad PR) is too costly to ignore.

For ports ready to ditch diesel, avoid fines, and future-proof their operations: BESS containers are your first (and best) step. And at Maxbo Solar, we’re here to help you take it.