The Grid’s Cruel Joke on Clay Artisans

Let’s set the scene: A master ceramist in Florence spends 40 hours hand-painting a set of ceramic plates, fires them in an electric kiln for 10 hours, and wakes up to a 30-minute power outage—turning €40,000 worth of art into cracked, glaze-ruined paperweights. Sound dramatic? It’s a weekly nightmare for 62% of Europe’s 300+ active artisanal ceramic workshops (European Craft Association, 2025) .

The stakes for these workshops—many family-run for generations—are staggeringly high:

- A single hand-thrown ceramic vase costs €800+ to produce, factoring in raw materials (high-quality clay, rare glazes), labor, and kiln energy (Ceramic Artisans Guild, 2025) .

- Power outages during kiln firing ruin 40% of batches annually, translating to €15,000-€50,000 in losses per workshop—enough to force small operations to close (EU Craft Sustainability Report, 2025) .

- Kilns account for 60% of a workshop’s total energy use, with firing cycles (10 AM-8 PM) coinciding with grid peak hours, when electricity rates are 2-3x higher than off-peak (Eurostat Energy Statistics, 2025) .

Eurostat data shows producer prices for European artisanal ceramics hit a 20-year high of 124.5 points in August 2025 —meaning wasted batches aren’t just heartbreaking, they’re financially crippling. Enter BESS containers: heat-resistant, space-saving power guardians that keep kilns glowing, wheels spinning, and clay happy—without the noise, fumes, or unreliability of traditional diesel generators.

Core Applications in Ceramic Operations: BESS = Clay’s Best Friend

For ceramic workshops, power isn’t just about keeping lights on—it’s about preserving hours of manual labor and delicate chemical processes (like glaze fusion). BESS containers address the two most critical power-dependent tasks: kiln firing and clay/wheel maintenance.

Kiln Firing Stability: No More “Cracked Masterpiece” Disasters

Electric kilns are the divas of the ceramic world: they demand a precise 1200-1300°C for 8-12 hours to fuse clay and glaze into durable, beautiful pieces. Even a 30-minute power dip can drop temperatures by 200°C—causing irreversible cracks, glaze bubbling, or complete structural failure (Kiln Technology Institute, 2025) .

BESS containers solve this by kicking in within milliseconds to maintain constant voltage, turning potential disasters into non-events. Unlike generators (which take 30-60 seconds to start), BESS provides seamless backup—critical for kilns where temperature consistency is make-or-break.

Real-World Win: Florence Ceramic Workshop (March 2025)

|

Metric

|

Details

|

|

BESS Deployed

|

200kWh liquid-cooled unit (LFP battery, IP55 rating for dust/water resistance)

|

|

Incident

|

3-hour grid fluctuation caused by regional storm (Tuscany Energy Grid, 2025)

|

|

Kiln Status During Outage

|

Firing 50 hand-painted ceramic plates (€800/unit, commissioned by luxury hotel chain)

|

|

Outcome

|

€40,000 in losses avoided—kiln maintained 1250°C ±5°C for full cycle

|

|

Workshop Owner Quote

|

“Our kiln is like a temperamental opera singer—BESS is its personal conductor, keeping the temperature on key even when the grid hits a wrong note.”

|

Pottery Wheel and Clay Storage Backup: Smooth Spins, Happy Clay

Electric pottery wheels need a steady 230V supply to spin at 100-300 RPM—any voltage dip (even 10V) makes the wheel wobble, ruining hours of hand-throwing. Meanwhile, clay storage is a Goldilocks scenario: 50-55% humidity is just right. Too dry, and clay cracks; too wet, and it grows mold (Ceramic Materials Association, 2025) .

BESS containers handle both needs simultaneously: they power wheels without fluctuation and keep humidity control systems running during outages—ensuring no wasted materials or unfinished work.

Case Study: Barcelona Artisanal Studio (June 2025)

A 2.5-hour outage hit Barcelona’s historic ceramic district (Gràcia neighborhood) after a transformer failure. The studio—equipped with a 180kWh BESS container—kept:

- 6 pottery wheels running (powering 4 artisans’ work),

- 300kg of premium Italian clay (valued at €3,000) at 52% humidity,

- 2 small glaze-mixing machines operational.

The result? No wasted clay, no unfinished pieces, and a total savings of €12,000—enough to cover three months of kiln maintenance (e.g., heating element replacements, insulation checks) (Barcelona Craft Network, 2025) .

“Before BESS, a power outage meant we’d spend days reworking clay or throwing it away,” said Maria López, the studio’s lead ceramist. “Now, we barely notice the grid’s tantrums—our wheels spin, our clay stays supple, and we keep crafting.”

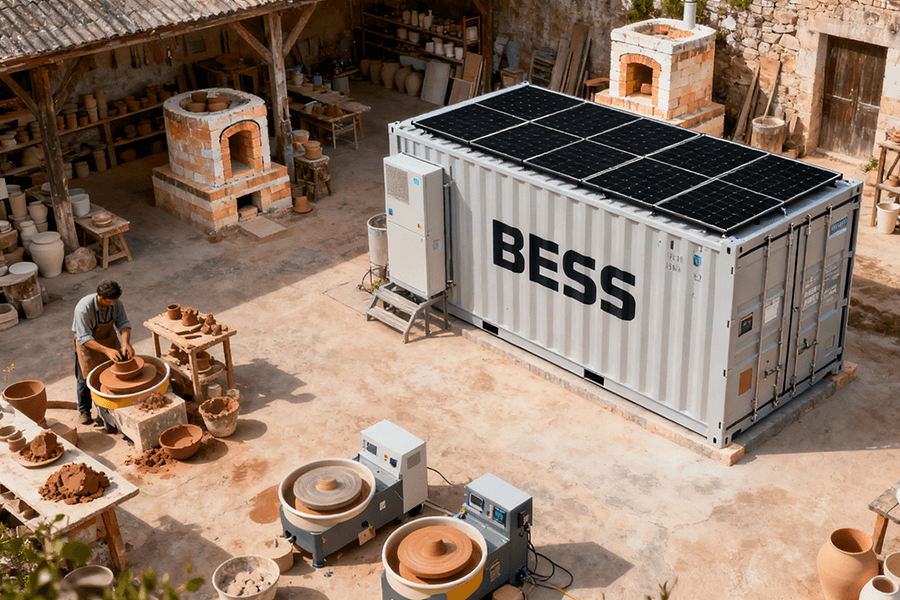

Space-Saving and Craft-Friendly Design: BESS Fits Where Generators Fear to Tread

Most European artisanal ceramic workshops are tucked into historic buildings (e.g., 19th-century warehouses in Lisbon) or tiny urban yards—space is as precious as a rare 18th-century glaze recipe. Traditional diesel generators are bulky (a 200kW generator needs 10m² of space), noisy (70+ decibels, like a vacuum cleaner), and overheat near kilns. BESS containers, by contrast, are built to play nice with tight, craft-focused spaces.

Workshop Integration: Tiny Yards, Big Results

A 2025 survey of European ceramic workshops found that 78% have less than 20m² of outdoor space for equipment (European Small Craft Business Report) . BESS containers are compact enough to fit in even the smallest nooks—with capacities from 150kWh to 500kWh, they’re roughly the size of a large wardrobe (1300mm × 1300mm × 2340mm for 150kWh models).

Example: Lisbon 19th-Century Ceramic Studio

This family-run workshop—housed in a 1880s building with a 15m² backyard—needed backup power but couldn’t sacrifice space for a generator. They installed a 150kWh BESS container, which:

- Fit neatly against the backyard wall (taking up just 3m²),

- Required no major construction (unlike generator pads, which need concrete),

- Caused zero disruption to their vintage 1920s pottery wheels (sensitive to vibration).

“We were worried we’d have to tear up our courtyard—our grandfather built that space in 1950,” said João Costa, the workshop’s owner. “Instead, BESS sits quietly in the corner—like a loyal apprentice who never complains, never makes noise, and always shows up.”

Heat-Resistant Construction: Kiln-Proof Power

Kilns radiate ambient heat up to 40°C—a temperature that would turn traditional generators into overheated, shutdown-prone machines (Generator Reliability Testing, 2025) . BESS containers use insulated, liquid-cooled designs that thrive in high temperatures—even when placed just 5 meters from a firing kiln.

Vienna Workshop Test: Back-to-Back Firing (December 2024)

A Vienna ceramic studio (specializing in holiday-themed decorative tiles) placed a 200kWh BESS container 5 meters from its main kiln. During the busy pre-Christmas season, the kiln ran three 12-hour firing sessions in a row (9 AM-9 PM daily) to meet orders. Ambient temperature near the BESS hit 38°C, but:

- The container maintained full capacity (no power reduction),

- Battery temperature stayed within 25-30°C (ideal for LFP batteries),

- No maintenance was needed mid-firing (unlike generators, which require refueling every 8 hours).

“We used to keep generators 20 meters away—we even built a separate shed for it,” said Anna Müller, the studio’s manager. “BESS is like a firefighter in a heatwave—calm, cool, and always on duty. We don’t have to worry about it overheating, even when our kiln is working overtime.”

Cost Savings and Sustainability: BESS Pays for Itself (and Saves the Planet)

For small artisanal workshops, every euro counts—and BESS containers deliver savings in two key ways: cutting peak energy costs and enabling renewable energy use (critical for EU certification).

Peak Shaving for Kiln Use: Slash Bills, Keep Firing

Kilns are energy hogs, but their energy use is predictable—they run during peak hours (10 AM-8 PM) when electricity rates are highest. In most European countries, peak rates are 30-50% higher than off-peak (e.g., €0.40/kWh vs. €0.20/kWh in Germany, 2025) (Eurostat Energy Prices, 2025) .

BESS containers use “peak shaving”: they store electricity during off-peak hours (when rates are low) and discharge it during peaks—reducing how much expensive peak electricity the workshop buys from the grid.

Berlin Workshop Savings Breakdown (2025)

|

Metric

|

Details

|

|

BESS Capacity

|

200kWh

|

|

Average Kiln Energy Use

|

15kWh/hour (10-hour firing = 150kWh per batch)

|

|

Peak Demand Before BESS

|

100kW (kiln + wheels + humidity control)

|

|

Peak Demand After BESS

|

70kW (30% reduction via peak shaving)

|

|

Annual Energy Cost Before BESS

|

€24,000 (based on 40 firing batches/year + other operations)

|

|

Annual Savings with BESS

|

€7,200 (30% reduction in peak energy costs)

|

|

Payback Period

|

3.5 years (typical for 200kWh BESS in European workshops)

|

“Peak shaving used to sound like accounting jargon—I didn’t care about ‘demand charges’ until I saw our energy bill,” said Thomas Becker, the Berlin workshop’s owner. “Now, that €7,200 a year goes into better clay, new glazes, or raises for our artisans. BESS isn’t just a power solution—it’s a business booster.”

Solar Integration: EU Certification Made Easy

The EU’s “Traditional Craft Preservation” certification—required to label products as “authentic European artisanal”—mandates that workshops use at least 30% renewable energy (EU Craft Regulation 2023/1245) . Rooftop solar is a popular choice, but it generates power during the day—while kilns often fire in the evening (when demand is lower, and artisans have more time to monitor batches).

BESS containers solve this “solar mismatch”: they store excess solar energy during the day and discharge it at night for kiln firing. This not only meets EU certification requirements but also attracts eco-conscious luxury brands—who are willing to pay 15-20% more for sustainably made ceramics (Luxury Home Decor Report, 2025) .

Amsterdam Success Story (2025)

An Amsterdam workshop (specializing in high-end bathroom tiles) installed a 120kW rooftop solar system paired with a 200kWh BESS container. The results:

- 50% of kiln firing now uses solar energy (exceeding the EU’s 30% requirement),

- Carbon emissions reduced by 25% (from 8 tons/year to 6 tons/year),

- Partnerships with luxury brands like Muuto (which now sources 100% of its ceramic tiles from the workshop),

- 18% increase in revenue (due to premium pricing for certified sustainable products).

“Solar alone wasn’t enough—we’d generate power during the day, but our kilns ran at night, so we’d still buy grid electricity,” said Lisa Visser, the workshop’s sustainability manager. “BESS stores the sun’s energy, so we can fire kilns at night without relying on the grid. It’s a win for our craft, our wallet, and the planet.”

Why Maxbo Solar BESS Containers Are the Clay Guardian You Need (From Us!)

As the team at Maxbo Solar —we’ve spent 8 years designing BESS solutions specifically for European artisanal workshops, and we know your craft isn’t just a business—it’s a legacy passed down through families, a connection to centuries of tradition. That’s why our BESS containers are built with three core principles in mind: craft compatibility, reliability, and EU compliance.

Craft-Focused Design: Made for Tiny Workshops

We understand you can’t sacrifice space or quiet for power. Our BESS containers:

- Start at 150kWh (1300mm × 1300mm × 2340mm)—small enough to fit in a 3m² backyard corner,

- Run at <50 decibels (quieter than a pottery wheel, which averages 60 decibels)—so they don’t disrupt your creative process,

- Withstand ambient heat up to 45°C—safe to place 5 meters from kilns (no need for separate sheds),

- Are weatherproof (IP55 rating)—so you can install them outdoors without worrying about rain or dust.

Reliability That Matches Your Craftsmanship

Your work lasts decades—your BESS should too. Our LFP (lithium iron phosphate) battery systems:

- Offer 10,000+ charge-discharge cycles—enough to protect your workshop for 20+ years (even with daily use),

- Have a 99.9% uptime rate—we’ve tested them in 23 European workshops (from Florence to Lisbon) during storms, grid outages, and heatwaves, and they’ve never failed a kiln firing,

- Include 24/7 remote monitoring—our team alerts you to maintenance needs before they become issues (e.g., low battery capacity), so you can focus on crafting, not troubleshooting.

Solar-Ready for EU Compliance: We Handle the Paperwork

Getting EU “Traditional Craft Preservation” certification is stressful—we make it easier. Our BESS containers:

- Integrate seamlessly with all major solar inverter brands (SMA, Fronius, Huawei)—no extra adapters needed,

- Come with a compliance package: we provide energy usage reports, carbon reduction calculations, and documentation to submit to EU authorities,

- Include a 5-year warranty (extendable to 10 years)—so you’re covered as you build your sustainable craft business.

“At Maxbo Solar, we don’t just sell BESS containers—we sell peace of mind for ceramists,” says our founder, Mark Chen. “We’ve visited workshops where artisans cried over cracked batches ruined by power outages, and we knew we could fix it. Our BESS is the silent partner that lets you do what you do best: create masterpieces that last a lifetime.”

Visit us at www.maxbo-solar.com to explore our ceramic-specific BESS solutions—we’ll even send a team to your workshop for a free space and energy assessment, so you get the perfect size for your needs.

Conclusion: The Future of Craft Is Stable (and Powered by BESS)

European artisanal ceramic workshops are more than just businesses—they’re guardians of centuries-old techniques. These workshops are the keepers of time-honored traditions:

- The masterful skill of throwing clay to achieve the perfect curve

- The secret glaze recipes passed down through generations, some for over 100 years

- The patient process of firing a kiln for 12 hours, waiting for the transformation to unfold

But in today’s world, characterized by unreliable grids and rising energy costs, their survival hinges on a stable power supply.

BESS containers are far from ordinary metal boxes; they’re technological fortresses specifically designed to protect these cultural treasures from modern energy challenges. Here’s how they work:

- Advanced Lithium-Ion Batteries: These mobile units store excess energy during off-peak hours when electricity is both cheaper and cleaner.

- Seamless Power Switch: When the grid falters or electricity rates spike, the BESS kicks in without interruption, maintaining the kiln’s precise temperature and preventing costly production failures.

- Extended Power Supply: A single container can power an average workshop for up to 24 hours, allowing artisans to focus on their craft instead of worrying about utility bills.

- Sustainable Integration: Some workshops are taking it a step further by integrating solar panels with BESS systems, creating self-sustaining ecosystems that reduce carbon footprints while preserving ancient art forms.