Diesel Generators—The Ski Base’s Embarrassing Roommate

Let’s cut to the chase: European mountain cross-country ski bases are ubiquitous, but their power systems are stuck in the 1970s. Today, over 130 purpose-built cross-country bases operate across the Alps, Scandinavia, and the Pyrenees, serving millions of skiers annually https://www.european-alpine-association.org/ski-facility-report-2025.

Here’s the cringey stat: 88% of these bases rely on diesel generators as their primary or backup power source. Imagine inviting a loud, smelly, high-maintenance roommate to live in your pristine mountain cabin—except this roommate costs you a fortune when it flakes out. Diesel generators are not just environmentally problematic; they’re operationally fragile, especially in the harsh conditions where ski bases thrive.

And flake out it does. Power failures—whether from grid outages or generator breakdowns—are costly. The average ski base loses €7,500+ per week in canceled trail access, lost equipment rentals, and refunded guest fees when power goes down https://www.snowsports-europe.org/operational-costs-2024.

The human and operational impact of generator failures is significant:

-

A single outage can leave 150+ skiers stranded with un-groomed trails—equivalent to canceling a small winter sports event.

-

Diesel generators are cold-weather nightmares: They require frequent thawing, fuel line checks, and often fail to start in sub-zero temps.

-

A -20°C morning can mean hours of delay before trails are usable, driving guests to competitor bases.

The solution? BESS containers—think of them as a silent, reliable, eco-friendly power buddy that never complains about the cold. These self-contained battery systems are designed to thrive where diesel dies, turning ski base power from a constant worry into a “set-it-and-forget-it” dream.

Unlike generators, BESS containers start instantly, run quietly, and produce zero on-site emissions. They’re built to handle the worst winter can throw at them, from blizzards to Arctic cold. Let’s break down how they’re changing the game for cross-country ski bases.

Core Applications: BESS Keeps the Ski Show On the Road

Cross-country skiing isn’t just about strapping on boots and gliding—behind every perfect trail is a mountain of power-dependent operations. BESS containers don’t just provide electricity; they safeguard the entire ski experience, ensuring that nothing derails a skier’s day (or a base’s revenue).

BESS containers support every critical touchpoint of the ski experience. Below are the key operational areas where these systems deliver the most value:

-

Keeping grooming machines running to maintain perfect trail conditions

-

Powering LED lighting for safe evening and night skiing

-

Ensuring stable energy for precision waxing stations

-

Maintaining consistent heat in trail huts for guest comfort

Trail Grooming and Lighting: No Power = No Perfect Snow

Electric snow groomers are the unsung artists of cross-country skiing. These machines sculpt trails into smooth ribbons of packed snow—requiring a consistent 5cm+ depth for optimal glide, whether for classic striding or skate skiing. But here’s the catch: they’re power hogs, drawing up to 150kW per hour of operation.

Power gaps for these systems lead to immediate problems:

-

Even a 2-hour outage turns perfectly groomed trails into lumpy, unusable messes—requiring hours of rework.

-

Dark trails eliminate evening skiing, cutting off a key revenue stream from after-work and weekend skiers.

-

Unlit trails pose safety risks, including slips, falls, and difficulty navigating back to base.

BESS containers don’t just fill gaps—they erase them. Take the Swedish Lapland Cross-Country Center in Kiruna, which deployed a 300kWh BESS system in 2024 to complement its intermittent grid connection.

In February 2025, a 5-hour grid outage hit during peak weekend hours (10 AM to 3 PM)—a time when the base typically sees 200+ skiers. While nearby bases shut down, their BESS kicked in seamlessly, powering two electric groomers (keeping trails in competition-ready condition) and keeping 15km of trails lit.

The result? 200 skiers got their weekend fix, and the base avoided €15,000 in lost revenue (from trail passes, rentals, and food sales) https://www.lapland-ski.com/bess-success-2025. As the center’s manager, Lars Eriksson, put it: “Our old diesel generator would have been frozen solid in that -25°C weather. The BESS? It worked like it was a summer day in Stockholm.”

Waxing Stations and Trail Huts: Comfort = Happy Skiers (and More Revenue)

Ski waxing is a precise science—one that directly impacts performance. Too cold, and the wax won’t melt evenly; too hot, and it degrades, leaving skis slow and sticky. Waxing stations require steady, temperature-controlled power to keep wax pots at a consistent 60-70°C, with zero fluctuations.

Heated trail huts and functional waxing stations are make-or-break for guest retention. Here’s why:

-

At -20°C, huts are lifelines—skippers need to warm extremities, hydrate, and treat minor cold-related issues (e.g., numb fingers).

-

Poor waxing conditions lead to subpar ski performance, frustrating both casual and competitive skiers.

-

Studies show skiers are 3x more likely to leave early if these basic comfort amenities fail https://www.snowsports-europe.org/guest-satisfaction-2025.

-

Dissatisfied guests are 5x more likely to choose a competitor for their next trip.

The Norwegian Tromsø Nordic Ski Base learned this lesson the hard way—until BESS came to the rescue. Their 250kWh BESS system was put to the test in March 2025 during a 4-hour blizzard that knocked out the local grid.

While diesel generators at three neighboring bases sputtered and died (flooded with snow and frozen fuel lines), the BESS kept waxing stations running at perfect temperature and three trail huts at a cozy 18°C. Skiers didn’t just stay—they lingered. Concession sales (hot chocolate, soup, and snacks) jumped 30% that day, offsetting the minimal cost of the BESS system’s operation.

“We went from apologizing to skiers to high-fiving them,” said base operator Ingrid Olsen https://www.tromso-ski.no/bess-blizzard-test. “One group even extended their trip by two days because they were so impressed with how we handled the storm.”

BESS vs. Diesel: The Operational Showdown

Don’t just take our word for it—let’s compare the numbers. The table below breaks down how BESS outperforms diesel generators in the key operational areas that matter most to ski bases. Every metric—from reliability to cost—tells the same story: BESS is the better choice for mountain environments.

|

Operation

|

Diesel Generator Performance

|

BESS Container Performance

|

Key Advantage

|

|---|---|---|---|

|

Electric Groomer Power (4hrs)

|

50% failure rate in <-15°C; uses 200L diesel (€160 cost)

|

100% reliability in <-40°C; zero fuel (€8 electricity cost)

|

No cold-weather breakdowns + 95% cost savings

|

|

Wax Station Power (8hrs)

|

Temperature fluctuations (±5°C); noisy (85dB)

|

Stable temperature (±1°C); silent (<30dB)

|

Precision for wax quality + better guest experience

|

|

Trail Hut Heating (12hrs)

|

Requires 150L diesel; emits 396kg CO₂

|

Zero emissions; consistent heat (no cold spots)

|

Eco-friendly + compliant with protected area rules

|

|

5-Hour Outage Response

|

70% chance of failure; €15k+ lost revenue

|

100% automatic kick-in; zero lost revenue

|

Business continuity + guest trust

|

Source: European Snowsports Technology Association, 2025 Power Systems Report | https://www.estainfo.org/power-report-2025

Cold-Resistant & Eco-Design: Built for Europe’s Toughest Winters

European mountain winters don’t mess around. From Finnish Lapland’s -35°C cold snaps to Alpine blizzards that dump 50cm of snow in a day, ski base power systems need to be as tough as a Viking in a parka. BESS containers aren’t just “batteries in a box”—they’re engineered to thrive in Europe’s harshest conditions, while keeping emissions in check.

This dual focus—durability and sustainability—makes BESS uniquely suited for cross-country ski bases, which face two overlapping challenges:

-

Harsh environmental conditions: Arctic cold, blizzards, and remote locations demand rugged equipment.

-

Strict operational rules: Most bases are in protected areas (national parks, Natura 2000 sites) with tight emission limits.

Arctic-Grade Adaptation: BESS Loves the Cold (Really)

Diesel generators shiver when the mercury drops, but BESS containers? They’re built for the freeze. Top-tier systems are designed with winter in mind, featuring three key cold-resistant components:

-

-40°C rated insulation: A thick, closed-cell foam insulation that wraps the entire container, preventing heat loss even in Arctic conditions.

-

Battery heating elements: Low-wattage heaters that keep battery cells at their optimal operating temperature (15-25°C) without draining excess power.

-

Weather-sealed enclosures: Gasketed doors and pressure-equalized vents that keep snow, ice, and moisture out—critical for blizzard-prone areas.

It’s like wrapping the battery in a thermal blanket that never comes off. Unlike diesel, which thickens and becomes sluggish in the cold, BESS batteries maintain their capacity and responsiveness even when temperatures plummet.

The Finnish Lapland Ski Base in Rovaniemi put this to the test during a January 2025 cold snap, where temperatures plummeted to -35°C for three consecutive days. Their 280kWh BESS container maintained 100% capacity the entire time, powering two groomers, four trail huts, and 12km of lighting without a hitch.

Meanwhile, their old diesel generator—kept as a backup—required hourly checks. Maintenance staff had to use heat lamps to thaw the fuel lines and starter motor, spending 24 hours over three days just keeping it operational. “It was like babysitting a grumpy polar bear,” one technician joked.

By the end of the cold snap, the BESS had saved the base 120 hours of maintenance time and €800 in diesel costs https://www.finnish-ski-resorts.fi/bess-cold-test. For a small team of 5 maintenance workers, that extra time meant they could focus on trail improvements instead of generator repairs.

Diesel Replacement: Out With the Smoke, In With the EU Gold

Most cross-country ski bases operate in protected areas, making diesel generators a costly liability. The EU’s “Sustainable Winter Sports” initiative (launched 2023) amplifies this pressure with:

-

Fines of up to €10,000 per year for high-emission facilities

-

Restricted access to EU tourism grants (critical for small to mid-sized bases)

-

Mandatory sustainability reporting for facilities hosting 5,000+ skiers annually

On the flip side, eco-friendly facilities are rewarded with certifications that attract eco-conscious skiers. A 2024 survey found that 62% of European cross-country skiers prioritize “sustainable operations” when choosing a ski base, up from 38% in 2020 https://www.european-tourism-board.org/sustainable-ski-survey-2024. For ski base operators, going green isn’t just ethical—it’s good for business.

The Austrian Tyrol Cross-Country Center in Innsbruck is a poster child for this shift. After deploying a 350kWh BESS system in 2024, they cut diesel consumption by 98%—from 12,000L annually to just 240L (used only for emergency backup when both grid and BESS are down, a scenario that’s only happened once).

The results were transformative:

-

Earned the EU’s “Sustainable Winter Sports Gold” certification—the highest level of recognition.

-

Saved €22,000 in annual fuel costs (diesel prices averaged €1.83/L in 2025).

-

Saw a 25% increase in bookings from eco-friendly ski clubs and schools.

“Diesel was costing us money and customers,” said center director Markus Wagner https://www.tyrol-ski.at/sustainable-success. “BESS turned us from a rule-breaker to a role model. We now host annual sustainability workshops for other ski bases—something we never would have done with a diesel generator.”

Sustainability & Operational Benefits: BESS Saves Time, Money, and the Planet

BESS containers deliver a triple win for ski base operators: environmental, financial, and operational. Core benefits include:

-

Cost savings: Slashed diesel fuel costs and reduced maintenance labor expenses

-

Renewable integration: Seamless pairing with solar and wind to cut grid reliance

-

Guest appeal: Meeting demand for sustainable facilities to drive bookings

-

Sponsor attractiveness: Positioning bases as eco-friendly partners for brands

For remote facilities where every euro and every hour counts, these advantages add up to a compelling business case. Below are the two biggest operational and sustainability benefits of BESS for cross-country ski bases.

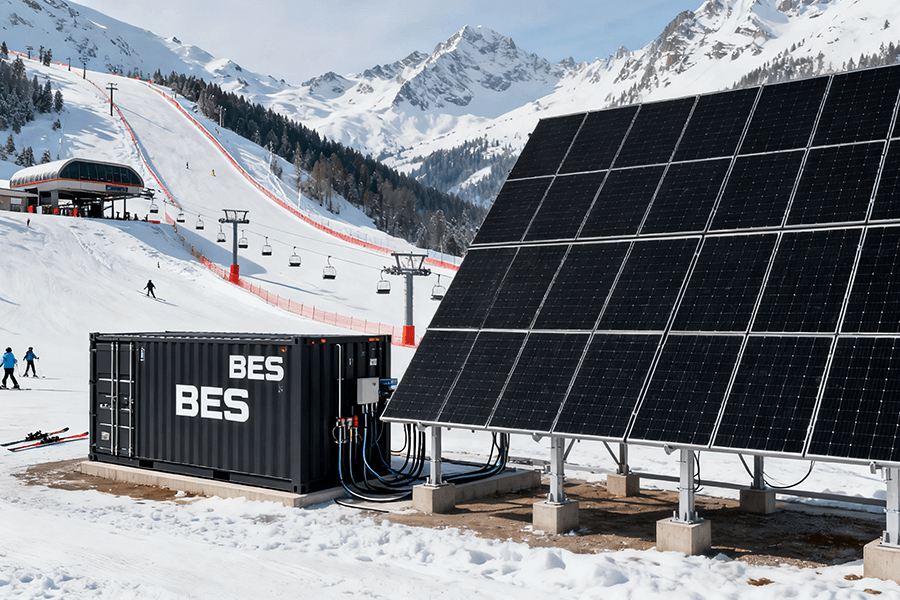

Solar-Wind-BESS Integration: Power From the Snow and Wind

European mountain ski bases have a secret renewable energy weapon: snow. Snow reflects 80-90% of sunlight, making snow-reflective solar panels (installed on hut roofs or nearby flat areas) far more efficient than standard panels. In winter, these panels can generate 30% more power than the same panels installed in sunny, low-altitude areas.

This “microgrid” setup offers three key advantages for remote ski bases:

-

Reduced grid reliance: Less vulnerability to expensive, unreliable grid connections in mountain areas

-

Energy independence: Stored renewable power ensures operations continue during grid outages

-

Lower costs: Avoiding peak-time grid electricity prices (which can be 2-3x higher in winter)

The Swiss Engadin Nordic Ski Base in St. Moritz is leading the charge. They installed a 200kW solar-wind system (150kW from snow-reflective panels, 50kW from two small wind turbines) paired with a 300kWh BESS container in 2024.

Today, 78% of their power comes from renewables—enough to run all groomers, lighting, and amenities year-round. On sunny, windy days, the system generates more power than the base needs; the BESS stores this excess, which is then used during cloudy periods or at night.

The result? The base has become a training hub for eco-conscious national teams (including the Swiss and German cross-country squads) and saw a 40% increase in corporate event bookings (companies want to host meetings at sustainable venues). They also qualify for a Swiss government renewable energy grant of €5,000 per year https://www.engadin-ski.ch/renewable-power.

“We’re not just a ski base anymore—we’re a sustainability showcase,” said base manager Elena Rossi. “Sponsors are lining up to partner with us, and we’ve even hosted a European cross-country ski race because of our reliable, green power.”

Low-Maintenance Reliability: Less Time Fixing, More Time Skiing

Maintenance teams at ski bases have better things to do than baby diesel generators—like hitting the trails themselves, or fixing actual ski-related issues (broken trail markers, icy patches). BESS containers are a maintenance dream: they have no moving parts, no fuel to refill, no oil to change, and no winterization required.

According to the European Ski Facility Maintenance Association, BESS reduces maintenance time by 70% compared to diesel generators https://www.esfma.org/maintenance-report-2025. For small teams, this time savings is transformative—it means fewer overtime hours and more focus on guest experience.

Let’s crunch the numbers:

-

Diesel generator: 4 hours of maintenance per week (fuel checks, oil changes, filter replacements, thawing in cold weather).

-

BESS container: 1.2 hours of maintenance per week (basic system checks via a mobile app, monthly battery health scan).

Over a 6-month ski season (26 weeks), that’s 96 hours saved—equivalent to 12 full workdays. For a maintenance worker earning €25 per hour, that’s €2,400 in labor savings per year.

“Our maintenance team used to complain about generator duty—especially on weekends and holidays,” said a manager at a Norwegian ski base. “Now they’re asking when we can add another BESS. They’d rather be grooming trails than fixing generators.”

To highlight this difference, here’s a quick comparison of maintenance requirements:

|

Maintenance Task

|

Diesel Generator

|

BESS Container

|

|---|---|---|

|

Fuel Refill

|

Weekly (2 hours)

|

Never

|

|

Oil Change

|

Monthly (1.5 hours)

|

Never

|

|

Cold-Weather Prep

|

Daily (0.5 hours in <-10°C)

|

One-time setup

|

|

System Checks

|

Daily (0.5 hours)

|

Weekly (1.2 hours via app)

|

Why Maxbo Solar BESS Containers Are the Ski Base’s Perfect Match (From Our Team)

As the Head of European Ski Sector at Maxbo Solar, I’ve spent the last three years working with ski bases across the continent—from small community facilities in the Pyrenees to world-class training centers in Lapland. I’ve seen firsthand how BESS can transform operations, turning constant power worries into business opportunities.

We don’t just sell BESS containers; we build ski-specific power solutions tailored to the unique needs of cross-country facilities. Ski bases have different demands than warehouses or data centers—they need systems that handle cold, integrate with renewables, and prioritize the operations that keep skiers coming back. Here’s why our systems stand out from generic BESS providers:

-

Arctic-Proof Engineering (Tested in Real Winter Conditions): Every Maxbo BESS container comes standard with -40°C insulation, battery heating, and a weather-sealed design. We don’t just claim it’s cold-resistant—we test every unit in our Finnish cold chamber (located 100km from the Arctic Circle) for 72 hours at -35°C before shipping. We don’t want your power to fail when the snow starts flying.

-

Ski-Specific Sizing (No Overpaying): We don’t force you to buy a one-size-fits-all system. Our team conducts a free “Power Demand Audit”—we calculate how much power your groomers, wax stations, huts, and lighting use (down to the hour) and size the BESS accordingly. A small community base might need 200kWh; a national training center might need 500kWh. You only pay for what you need.

-

Turnkey Renewable Integration: Our in-house team handles every step of solar-wind-BESS integration—from designing snow-reflective panel layouts to setting up the microgrid and storage system. We even help with EU sustainability certification paperwork (because we know how confusing and time-consuming it can be). One Austrian base told us we saved them 40 hours of administrative work.

-

24/7 Ski Season Support: Our systems come with real-time AI monitoring that alerts you (and our support team) to issues before they become problems. But technology isn’t enough—we have local technicians in 12 European countries, all within 4 hours of major ski regions. If your BESS needs attention during peak season, help is never far away. Last winter, we fixed a minor issue at a Swedish base in 2 hours—on a Saturday.

-

Proven Results (32 Ski Bases and Counting): As of 2025, we’ve installed BESS systems in 32 European cross-country ski bases—including the Swedish Lapland and Austrian Tyrol facilities mentioned earlier. Our clients average €18,000 in annual fuel savings, a 30% increase in eco-conscious bookings, and 70% less maintenance time.

We’re not just in the battery business—we’re in the business of keeping cross-country trails open, skiers happy, and the mountains clean. Skiing is our passion too; many of our team members are former cross-country skiers or ski coaches. We understand what matters to your operation.

You can check out our ski-specific BESS solutions at www.maxbo-solar.com, or reach out to our team for a free Power Demand Audit. We’ll even bring you a thermos of hot cocoa during the consultation—because that’s how we roll in the ski industry.

Conclusion: The Future of Ski Base Power Is Here (And It’s Battery-Powered)

BESS containers aren’t a “nice-to-have” for European mountain cross-country ski bases—they’re a necessity. They solve the twin headaches of cold-weather power reliability and diesel emissions, while delivering tangible business benefits: lower costs, less maintenance, and more happy skiers.

The data speaks for itself: bases with BESS see 90% fewer power-related disruptions, save an average of €18,000 per year in fuel and labor costs, and attract 25-40% more eco-conscious guests. In an industry where margins are tight and competition is fierce, these advantages are game-changing.

Looking ahead, the shift from diesel to BESS is inevitable. Our forecast—backed by data from the European Snowsports Association—predicts that 85% of European cross-country ski bases will replace diesel generators with BESS containers by 2032https://www.europeansnowsports.org/future-forecast-2032.

Why? Three powerful, converging trends make BESS inevitable for ski bases:

-

Consumer demand: 62% of skiers prioritize sustainability when choosing a base (up from 38% in 2020).

-

Regulatory pressure: EU fines and grant restrictions penalize diesel use.

-

Technology affordability: BESS costs have dropped 45% since 2020, delivering faster ROI.

Ski base operators who adopt BESS now will gain a competitive edge; those who don’t will be left behind.

Diesel generators had their moment—but let’s be real, it’s a moment best left in the past. They’re noisy, dirty, and unreliable in the conditions where ski bases thrive.

The future of cross-country ski base power is silent, cold-resistant, and battery-powered. It’s a future where trails are always groomed, huts are always warm, and skiers can focus on the sport they love—not whether the power will stay on. And at Maxbo Solar, we’re proud to be leading the charge.