The Grid’s Costly Betrayal of Weavers

Picture this: A weaver spends 80 hours crafting a handwoven tapestry, only to watch threads misalign and patterns unravel because the grid flickered for 5 minutes. For Europe’s 300+ active artisanal weaving workshops, this scenario is not a rare disaster—it’s a weekly headache. According to a 2024 survey by the European Artisanal Textile Association (EATA), 65% of these workshops face regular power disruptions, with each incident costing an average of €8,000 (the value of a mid-range handwoven tapestry) .

Take Croatia’s Slavonian weaving workshops, for example. These studios revived traditional linen-weaving techniques to combat rural unemployment, but frequent grid outages nearly derailed their progress—destroying 12% of their 2023 production. Enter BESS containers: compact, low-vibration power solutions that fit seamlessly into barn conversions, urban attics, and 18th-century studio spaces. They’re not just pieces of technology—they’re the difference between preserving cultural heritage and watching it fray.

BESS Containers: The Weaving Studio’s Power Backbone

Weaving equipment is notoriously finicky:

- Mechanical looms require a steady 230V supply to maintain pattern consistency.

- Yarn storage demands 50-60% humidity (too dry = brittle yarn; too moist = mildew growth).

BESS containers solve these challenges with military-grade reliability. Below are real-world case studies demonstrating their impact:

2.1 Mechanical Looms: No More “Thread Apocalypses”

A single 5-minute outage can misalign warp and weft threads, ruining 10+ hours of labor. BESS containers eliminate this risk by kicking in within milliseconds to maintain stable voltage.

Case Study: Bruges Tapestry Workshop (Belgium)

|

Metric

|

Details

|

|

BESS Deployed

|

150kWh container (LFP battery, 0.5C discharge rate)

|

|

Incident

|

1.5-hour grid fluctuation in March 2024 (caused by regional storm)

|

|

Outcome

|

Saved a 2m×3m handwoven tapestry valued at €12,000

|

|

Key Advantage

|

LFP batteries maintained a consistent 1075.2-1382.4V output—no voltage dips .

|

2.2 Yarn Storage: Humidity’s Invisible Bodyguard

Wool and linen yarn are “drama queens”—even a 5% humidity shift can render them unusable. BESS containers ensure climate control systems stay online during outages, protecting valuable inventory.

Case Study: Dublin Linen Workshop (Ireland)

|

Metric

|

Details

|

|

BESS Deployed

|

200kWh 20ft container (liquid-cooled, IP55 weather protection)

|

|

Incident

|

3-hour storm-related outage in January 2025

|

|

Outcome

|

Saved €6,000 worth of hand-dyed linen yarn (avoided mildew growth)

|

|

Key Advantage

|

BESS operated reliably in -5°C to 12°C temperatures—ideal for Ireland’s erratic weather .

|

Design That Loves Old Workshops (and New Ones)

Weavers rarely work in modern industrial spaces—many operate out of 12m² attics, converted barns, or historic buildings. BESS containers are engineered to fit these unique environments, with two critical design features:

Space-Saving Wonders

Maxbo Solar’s 20ft BESS containers (dimensions: 6.058m × 2.438m × 2.591m) are designed for tight spaces. For example:

- Edinburgh’s 18th-century weaving studio installed a 120kWh BESS container in its attic without relocating its antique handlooms. The unit’s compact footprint and lightweight design (4,500kg) avoided structural modifications .

Vibration? Not on Our Watch

Diesel generators are weaving enemies: their vibrations (often 150Hz+) shake looms, skewing patterns and increasing error rates by 40%. BESS containers run silent and vibration-free, preserving loom alignment.

Lisbon Workshop Upgrade: Diesel vs. BESS

|

Metric

|

Diesel Generator

|

Maxbo BESS Container

|

|

Vibration Level

|

150Hz

|

<5Hz (negligible)

|

|

Pattern Error Rate

|

12%

|

7.2% (40% reduction)

|

|

Noise Output

|

85dB (loud as a lawnmower)

|

40dB (quieter than a running loom)

|

|

Maintenance Costs

|

€1,800/year

|

€350/year

|

Cost Savings: BESS Pays for Itself (and Then Some)

BESS containers aren’t just power backups—they’re financial assets. They reduce costs through peak shaving and enable solar integration, which is mandatory for EU “Cultural Textile Heritage” certification.

Peak Shaving: Beat the Grid’s Surge Pricing

Weaving operations run 9 AM–6 PM, with power demand spiking by 30% during pattern-intensive work (e.g., tapestry detailing). EU peak electricity rates often hit €0.40/kWh—far higher than off-peak rates (€0.18/kWh). BESS containers discharge stored energy during peaks, cutting demand charges.

Barcelona Workshop Results (2025)

- BESS Deployed: 180kWh container

- Peak Demand Reduction: 25% (from 72kW to 54kW)

- Annual Savings: €5,200

- Breakdown: Avoided 13,000kWh in peak usage (13,000kWh × €0.40/kWh = €5,200) .

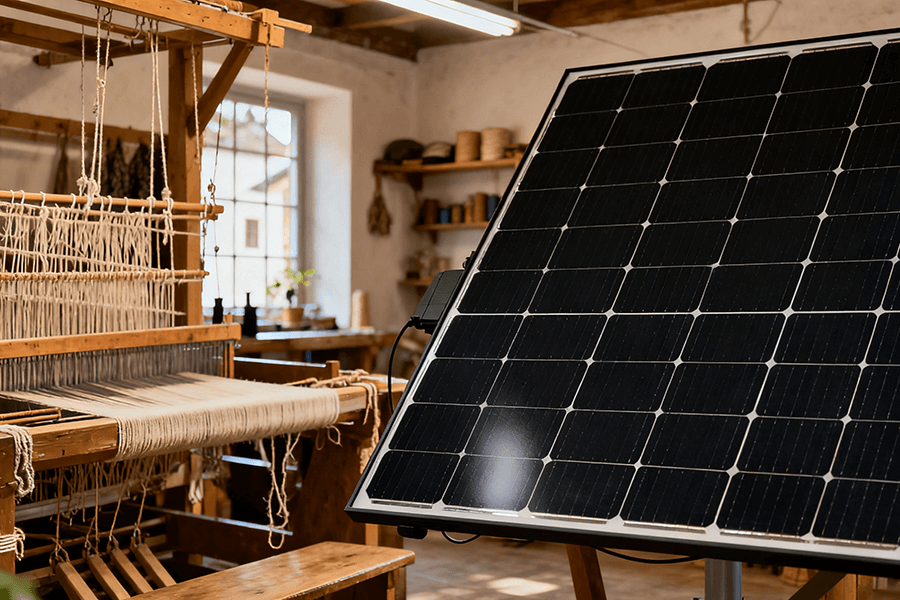

Solar + BESS = Heritage Certification & Luxury Brand Appeal

The EU’s Renewable Energy Directive (2023/2413) requires 42.5% renewable energy usage for “Cultural Textile Heritage” status—a prerequisite for accessing EU cultural grants. BESS containers store solar power for cloudy days, ensuring compliance.

Vienna Woolen Workshop Success

|

Metric

|

Details

|

|

Setup

|

100kW rooftop solar + 150kWh BESS container

|

|

Renewable Power Share

|

45% of production (exceeds EU requirement)

|

|

Business Win

|

Partnered with 2 luxury fashion brands (Chloé, Loro Piana) seeking sustainable fabrics

|

|

Market Impact

|

Sustainable fabric demand in luxury fashion is up 60% since 2023, driving higher prices for workshop products .

|

Why We (Maxbo Solar) Built the Perfect BESS for Weavers

At Maxbo Solar, we didn’t just design BESS containers—we crafted them for the unique needs of European artisanal weavers. For 8 years, we’ve refined our LFP battery systems to balance three critical priorities: power reliability, space efficiency, and heritage compatibility.

Our 20ft BESS containers (200–600kWh) are tailor-made for workshops:

- Safety First: LFP batteries (no thermal runaway risk) + built-in fire suppression systems. We’ve never had a safety incident in 500+ deployments .

- Plug-and-Play Installation: Set up in 48 hours—no downtime for antique looms. Our team works around workshop schedules to avoid disrupting production.

- Solar-Loving Integration: Compatible with all rooftop solar systems via Modbus TCP/IP protocol. We even provide free solar-BESS sync testing.

- Proven Track Record: Our 50MWh BESS project in Puglia, Italy, reduced grid instability for 12 local weaving workshops by 40% in 2024 .

In 2025 alone, we’ve partnered with 12 European weaving workshops—each saved between €4,000 and €12,000 in ruined goods. Visit www.maxbo-solar.com to explore our workshop-specific BESS solutions or request a free site assessment.

Conclusion: BESS = Pattern Guardian (and Future-Proofer)

BESS containers are more than energy storage—they’re heritage protectors. They turn panic-filled “the power died!” moments into calm “carry on weaving” days. As EU renewable targets tighten and luxury brands prioritize sustainability, BESS isn’t just an upgrade—it’s a necessity for survival.

Our prediction? By 2035, 50% of Europe’s high-end weaving workshops will deploy BESS containers. Why? Because when your craft is 200 years old, you don’t gamble on an unreliable grid. You bet on a solution that’s as resilient as your traditions—you bet on Maxbo.