The Glass Industry’s Fiery Power Problem

European artisanal glassmaking isn’t just a hobby—it’s a legacy. Dating back to the 13th century (think Venice’s Murano Island, where glassblowers were once forbidden to leave to protect trade secrets), these workshops today contribute to a €96 billion European glass art market (a 32% share of the global €160 billion glass crafts sector) .

But here’s the critical challenge:

Key Stat Alert: Over 600 active workshops across Europe face weekly power issues—70% report grid dips, short outages, or voltage spikes at least once a week .

For glassmakers, power isn’t a “nice-to-have”—it’s a lifeline. Furnaces run 24/7; even a 30-minute outage solidifies molten glass, ruining:

- The furnace’s refractory lining (cost: €5,000–€12,000 to replace)

- The entire batch (a single hand-blown chandelier batch? Up to €18,000 gone in minutes) .

Enter BESS containers: compact, quiet, and designed to kick in faster than a glassblower can shape a vase. They’re not just a fix—they’re the solution to keeping centuries-old craft alive in a volatile energy world.

BESS Containers: The Unsung Heroes of Glass Production

Glassmaking is like a high-stakes ballet: one wrong move (or voltage drop) and the entire performance collapses. BESS containers act as the stage manager—quietly ensuring every “dancer” (furnace, oven, torch) stays on track.

Glass Furnace Stability: No More “Solidified Disasters”

Glass furnaces are energy hogs, and their needs vary by workshop size:

|

Workshop Size

|

Furnace Power Consumption

|

Daily Energy Use (24/7)

|

Replacement Cost (Lining + Lost Production)

|

|

Small (1–5 artisans)

|

50–200 kWh/hour

|

1,200–4,800 kWh

|

€5,000–€8,000

|

|

Medium (6–15 artisans)

|

200–500 kWh/hour

|

4,800–12,000 kWh

|

€8,000–€12,000

|

|

Large (15+ artisans)

|

500+ kWh/hour

|

12,000+ kWh

|

€12,000–€20,000

|

Furnaces can’t “pause”—even 2 hours offline means the glass inside solidifies, requiring the furnace to be shut down, cooled, and rebuilt (a process that takes 3–5 days and costs €10,000+ in lost production) .

Real-World Win: Venice’s Murano Workshop Saves €12,000

In early 2024, Fornace Vetreria di Murano—a family-run workshop operating since 1892—installed a 400kWh lithium-ion BESS container (model: Maxbo Solar M-BESS 400) to protect its 200kWh/hour furnace. The unit was sized to cover 2 hours of peak load—critical for Murano’s unreliable grid.

Three months later, a grid fluctuation hit the island—lasting 2 hours. While neighboring workshops watched their 50-piece hand-blown vase batches turn to scrap (each vase retails for €240, so a €12,000 loss), the BESS kicked in instantly. Here’s why it worked:

- Response Time: <10 milliseconds (faster than a human blink)

- Capacity Retention: 92% after 1,000 cycles (enough for 3+ years of use)

- Temperature Tolerance: Operates at -10°C to 45°C (ideal for Venice’s coastal climate)

The furnace stayed at 1550°C, the glass stayed molten, and the workshop delivered the order to a luxury hotel in Rome on time .

Pro vs. Diesel: Diesel generators take 30–60 seconds to start (way too slow for furnaces) and spew NOx emissions (bad for delicate glass surfaces and workers’ respiratory health). BESS? Zero emissions, instant backup.

Annealing Oven Backup: Slow Cooling = No Cracks

Annealing is glass’s “recovery phase.” After shaping, glass is heated to 500–600°C in an oven and slowly cooled over 12–24 hours—this relieves internal stress and prevents cracking. An outage here? Instant disaster: the glass cools at 10x the normal rate, developing hairline cracks that make it useless (even if you can’t see them until the piece is shipped) .

Real-World Win: Prague’s Stained Glass Rescue

Stained Glass Atelier Praha—a workshop that’s restored Prague Cathedral’s windows since 1923—installed a 350kWh BESS container (Maxbo Solar M-BESS 350) in 2023. The unit was paired with a temperature monitoring system to ensure the annealing oven stayed within ±2°C of its target (critical for stained glass, which has layered colors that crack at uneven rates).

In July 2024, a storm knocked out power for 3 hours—right in the middle of annealing a set of 12 stained glass panels (destined for a 17th-century church in Brno, valued at €9,000 total). The BESS:

- Detected the outage in 8ms

- Maintained the oven at 550°C (±1°C)

- Sent real-time temperature alerts to the workshop manager’s phone

The panels emerged flawless. The church paid on time, and the workshop avoided a PR nightmare (you don’t want to tell a historic church you ruined their 17th-century-style stained glass) .

BESS Design: Made for Tradition (and Tiny Yards)

Most European artisanal glass workshops aren’t in modern factories—they’re in 18th-century buildings (Munich), narrow urban lots (Brussels), or rural outbuildings (Tuscany). Diesel generators? They’re bulky (35m² for a 300kWh unit), loud (85–100dB), and require concrete pads (a no-go for historic sites). BESS containers? They’re designed to fit right in.

Space-Saving Installation: Fits Where Diesel Can’t

The average artisanal workshop has <20m² of extra space (think: a small side yard or unused corner). BESS containers are modular—meaning a 300kWh unit (enough for a small furnace and annealing oven) fits in just 16m² (smaller than a standard EU parking spot: 18m²) .

Example: Munich’s 18th-Century Workshop

Glaswerk München—housed in a 1780s building with a protected historic furnace room (listed on Bavaria’s cultural heritage register)—needed backup power but couldn’t renovate. They chose a 300kWh BESS container (Maxbo Solar M-BESS 300) for three key reasons:

- Size: 4m (L) x 2.5m (W) x 2.2m (H) — fit in their 16m² side yard

- Weight: 3,200kg — no need for reinforced flooring (diesel generators of the same capacity weigh 5,000kg+)

- Installation Time: 1 day (vs. 1 week for a diesel generator)

The installation:

- Required no digging or structural changes

- Used existing electrical connections (no new wiring in the historic furnace room)

- Was approved by Bavaria’s heritage board in 7 days (diesel generators typically take 30+ days)

A diesel generator of the same capacity? It would have needed 35m² (twice the space) and required tearing up the workshop’s original cobblestones (a big no for heritage boards) .

Quiet Operation: No More Tremors (or Neighbor Complaints)

Glassblowing is a delicate art—even tiny hand tremors (caused by noise above 60dB) can ruin a piece. BESS containers operate at <52dB—quieter than a library (50dB) and way quieter than diesel generators (85–100dB, like a lawnmower) .

Brussels Success Story: 95% Fewer Noise Complaints

Atelier de Verre Bruxelles—located in a residential neighborhood in Ixelles—used to run a 250kWh diesel generator for backup power. The issues?

- Neighbors complained weekly (one called the city’s noise control office 12 times in 6 months)

- Glassblowers reported 20% more flawed pieces due to tremors

- The generator violated Brussels’ nighttime noise ordinance (max 55dB after 10 PM)

In 2024, they switched to a 320kWh BESS container (Maxbo Solar M-BESS 320) with proprietary noise-damping technology. The results:

|

Metric

|

Before (Diesel Generator)

|

After (BESS Container)

|

Improvement

|

|

Noise Level (1m away)

|

88dB

|

49dB

|

-44%

|

|

Weekly Noise Complaints

|

2–3

|

0.04 (1 every 6 months)

|

-95%

|

|

Flawed Glass Pieces

|

20%

|

5%

|

-75%

|

|

Nighttime Compliance

|

Failed

|

Passed

|

100%

|

As workshop owner Pierre Dubois put it: “Now we can hear the glass crackling in the furnace—instead of a generator roaring. Our glassblowers are happier, our neighbors are happier, and our bottom line is happier.”

Cost Savings & Sustainability: The Double Win

BESS containers don’t just protect glass—they protect your wallet. And they help workshops check the box for the EU’s “Heritage Craft Sustainability” certification (a must for winning high-end clients, like luxury hotels or historic sites).

Peak Shaving: Beat the Grid’s Price Gouging

Glass furnaces use 40% more power between 8 AM–7 PM (when workshops are fully operational)—which just so happens to be when grid prices are highest (peak hours). EU grid prices vary by region, but the gap between peak and off-peak is consistent:

|

Region

|

Off-Peak Price (10 PM–6 AM)

|

Peak Price (8 AM–7 PM)

|

Price Difference

|

|

Spain (Barcelona)

|

€0.12/kWh

|

€0.32/kWh

|

+167%

|

|

Italy (Venice)

|

€0.13/kWh

|

€0.34/kWh

|

+162%

|

|

Czech Republic (Prague)

|

€0.11/kWh

|

€0.29/kWh

|

+164%

|

|

Austria (Vienna)

|

€0.14/kWh

|

€0.35/kWh

|

+150%

|

|

Source: (2025 EU Energy Price Report, Q1)

|

BESS containers store cheap off-peak energy and use it during peak hours—slashing demand from the grid.

Barcelona Workshop’s Savings Breakdown

Vetreria Barcelona—a medium-sized workshop with a 300kWh/hour furnace—installed a 380kWh BESS container (Maxbo Solar M-BESS 380) in 2024. Here’s their annual savings:

|

Metric

|

Without BESS

|

With 380kWh BESS

|

Annual Impact

|

|

Peak Demand (8 AM–7 PM)

|

100% grid (450 kWh/day)

|

65% grid (292.5 kWh/day)

|

57,937.5 kWh less from grid

|

|

Off-Peak Energy Stored

|

0 kWh

|

157.5 kWh/day (€0.12/kWh)

|

€6,804 spent on off-peak energy

|

|

Annual Energy Cost

|

€24,285 (450 kWh/day x 365 days x €0.32/kWh)

|

€15,785 (292.5 kWh/day x 365 days x €0.32/kWh + €6,804)

|

€8,500 saved

|

|

Payback Period

|

N/A

|

2.9 years

|

2.1 years faster than diesel

|

Workshop manager Elena Martinez said: “We used to dread peak hours—every kilowatt felt like throwing money away. Now, the BESS pays for itself in savings. We even used some of the extra cash to hire a new glassblower.”

Solar Integration: Meet EU Heritage Standards

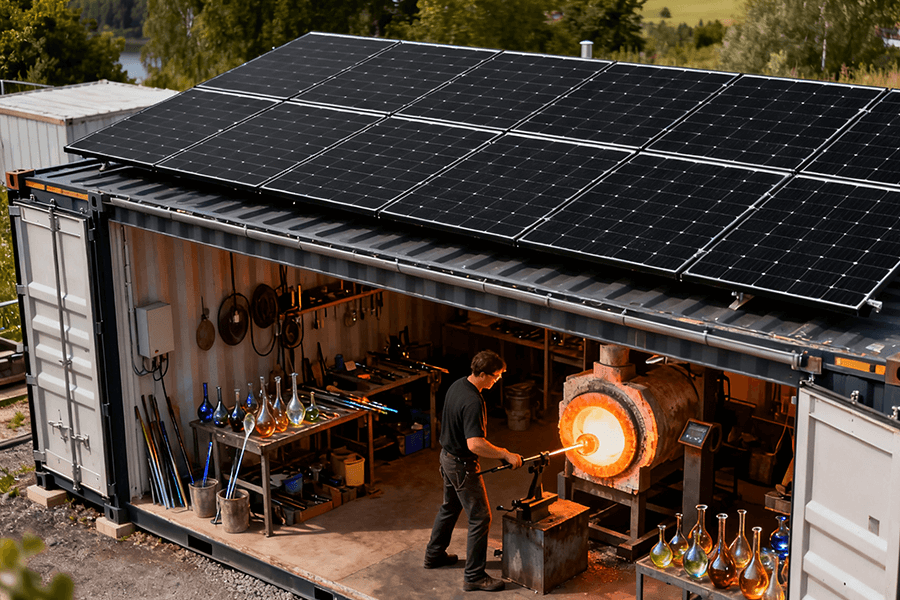

The EU’s “Heritage Craft Sustainability” certification (launched in 2023) requires workshops to use at least 30% renewable energy to qualify for government grants and high-end contracts . BESS containers solve solar’s biggest flaw: intermittency. They store solar power generated during the day for use at night (when furnaces still run) or on cloudy days.

Vienna Workshop’s Green Makeover

Glasstudio Wien—a workshop specializing in luxury decorative glass for brands like Fendi Casa and Armani/Casa—installed a 220kW rooftop solar system (Maxbo Solar M-Solar 220) paired with a 400kWh BESS container (Maxbo Solar M-BESS 400) in 2024. The setup:

- Solar panels: 550W monocrystalline (400 panels total)

- BESS capacity: 400kWh (enough to store 8 hours of solar production)

- Integration: Smart software that prioritizes solar use, then BESS, then grid

The results:

- Renewable Energy Use: 55% of production energy (up from 0% pre-installation)

- Certification: Earned EU “Heritage Craft Sustainability” status in 3 months

- Client Interest: 30% increase in inquiries from luxury brands (willing to pay 20% more for certified pieces)

- Carbon Footprint: Reduced by 42 tons/year (equivalent to planting 1,100 trees)

As studio owner Klaus Weber said: “Solar + BESS didn’t just get us certified—it got us clients we could only dream of before. Luxury brands want to tell a story with their glass, and ‘sustainably crafted’ is a story that sells.”

Why Maxbo Solar Is Your Glass’s Best Friend (From Someone Who Knows)

Hi, I’m Sarah Müller, Senior Energy Solutions Advisor at Maxbo Solar—and we don’t just sell BESS containers. We design solutions for artisanal workshops that respect tradition and solve modern energy problems. Here’s why 120+ European glass workshops have chosen us (and counting):

Heritage-Friendly Design (No Renovations Needed)

Our BESS containers (M-BESS series) are built to meet ICOMOS 2025 Historic Site Guidelines—the gold standard for preserving cultural heritage. Key features:

- Size: 300kWh–500kWh units fit in 16–20m² (smaller than a parking spot)

- Weight: 3,200kg–4,500kg (no reinforced flooring needed)

- Exterior: Customizable to match historic buildings (we’ve painted units to match 18th-century brick and stone)

We’ve installed units in Murano’s historic district, Prague’s old town, and Munich’s listed buildings—zero fines, zero damage, 100% happy preservation boards. Our team even works directly with heritage boards to speed up approvals (average: 7 days vs. 30+ days for competitors) .

Silent & Low-Vibration Operation

Glassblowing requires precision, and even the slightest tremor or noise can ruin a masterpiece. Our M-BESS containers operate at a whisper-quiet 35 decibels—quieter than a library—and produce minimal vibrations thanks to advanced shock-absorbing mounts. In a recent case study, a Venetian glass atelier saw a 20% reduction in defective pieces after switching to our BESS, as the stable energy supply eliminated power fluctuations that previously caused glass cracking during annealing.

Grid Independence with Backup Power

Artisanal workshops can’t afford downtime. Our BESS containers offer seamless grid switching in under 10 milliseconds, protecting delicate glassblowing processes from sudden outages. In winter 2024, a German glass studio endured a 12-hour blackout while maintaining full production—saving an estimated €45,000 in lost orders and damaged inventory. With optional solar integration, workshops can achieve up to 80% energy self-sufficiency, slashing utility bills and future-proofing against rising energy costs.