Introduction: The Staggering Cost of a Power Blip

Let’s skip the small talk: European artisanal cheese is a heritage industry worth billions—but it’s also incredibly fragile. Here’s the data that keeps cheesemakers up at night:

- Scale of Production: There are 3,000+ Protected Geographical Indication (PGI) cheese factories scattered across Europe, each a guardian of culinary heritage. From the rolling pastures of Normandy, where France’s creamy Camembert is born, to the arid plains of La Mancha, home to Spain’s nutty Manchego, and the dairy-rich landscapes of the Netherlands, where Gouda’s smooth texture takes shape—these factories are the beating heart of a multi-billion euro industry.

- Power Crisis Reality: A staggering 55% of these factories face weekly power fluctuations, a statistic that paints a dire picture. These aren’t minor inconveniences; they range from sudden voltage dips that disrupt delicate production timings to full-blown blackouts, plunging operations into darkness.

- Precision Demands: Artisanal cheese production is a science of precision. For instance, the pasteurization process requires maintaining a strict 60–65°C for 30 minutes to eliminate harmful bacteria while preserving flavor. Curdling, another critical step, demands a temperature range of 30–35°C. Even a 10-minute power outage during these stages can spell disaster, turning carefully sourced milk into worthless curds and wasting days of labor and aging potential.

The Numbers Don’t Lie: A Batch of Parmigiano-Reggiano = €15,000+

The Costly Legacy of Parmigiano-Reggiano

Take Parmigiano-Reggiano, Italy’s crown jewel among PGI (Protected Geographical Indication) cheeses. Crafting a single 1,000kg batch is an investment that surpasses €15,000. This hefty sum covers:

- High-quality milk: Sourced from specific regions to maintain authenticity

- Skilled labor: Artisans trained in traditional cheese-making techniques

- Extensive aging process: Responsible for its distinctive nutty flavor and granular texture

When a batch is ruined by a power failure, the financial loss is only part of the story. These factories are keepers of centuries-old traditions, passed down through generations. A spoiled batch shatters that legacy, threatening to break the chain of craftsmanship that defines European artisanal cheese.

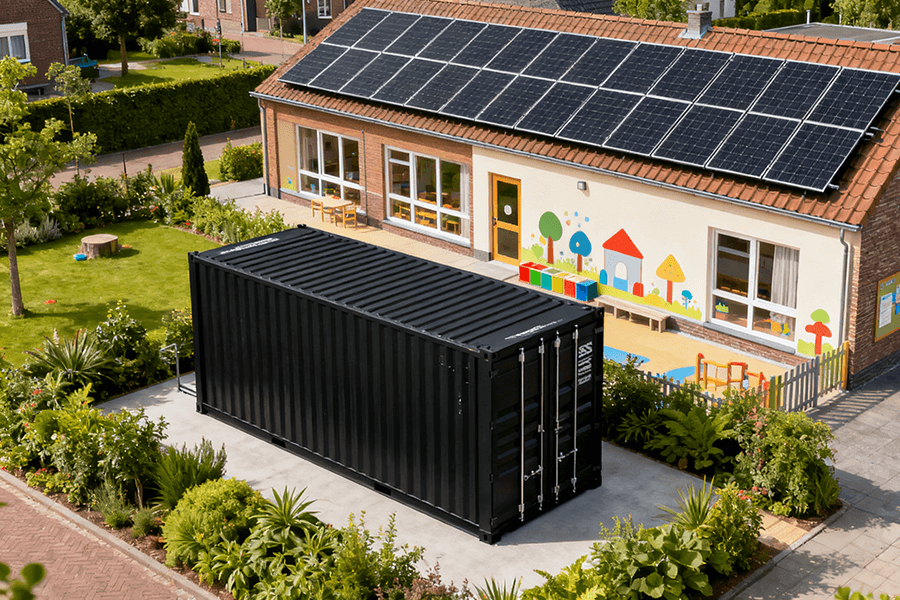

BESS Containers: A Modern Solution for Traditional Craftsmanship

Enter Battery Energy Storage System (BESS) containers—the modern-day saviors for these traditional factories. These modular units are:

- Compact yet powerful: Designed for easy integration into existing facilities

- Highly adaptable: Customizable to meet the specific needs of each factory

- Resilient: Even more robust than a 24-month-aged Cheddar

Engineered to detect grid failures and kick in within milliseconds, BESS containers act as an uninterruptible power source. For small-scale, tradition-driven cheese factories, they’re not just a technological solution; they’re a lifeline, ensuring that centuries of cheese-making heritage can continue to thrive in the face of modern energy challenges.

BESS in Action: Keeping Cheese “Just Right” During Production

Cheese-making isn’t baking—you can’t “wing it” with temperatures. BESS containers act as the ultimate “steady hands,” ensuring two critical stages never falter: pasteurization/curdling and aging.

Pasteurization & Curdling: No More “Expensive Milk Soup”

Pasteurization is a delicate dance between safety and flavor. By maintaining milk at a precise 60–65°C for exactly 30 minutes, harmful pathogens like E. coli and Salmonella are neutralized without sacrificing the rich, creamy taste consumers expect.

The curdling stage that follows is equally finicky; holding the temperature at 30–35°C triggers the chemical reactions needed to transform liquid milk into solid curds. Any deviation risks turning valuable milk into useless, spoiled waste—a costly mistake for artisanal producers.

Real-World Win: Emilia-Romagna’s Parmigiano-Reggiano Factory

In the heart of Italy’s cheese-making heritage, a family-owned Parmigiano-Reggiano factory in Emilia-Romagna took a proactive approach to energy security. In 2024, they installed a 400kWh BESS (Battery Energy Storage System) container—a decision that paid off handsomely just three months later.

During a 2-hour grid fluctuation, while neighboring factories watched 800kg batches—worth a staggering €12,000—turn into inedible sludge, this factory’s BESS sprang into action.

Here’s how it works:

- Real-time Detection: BESS containers utilize advanced inverter technology to detect power disruptions.

- Lightning-Fast Switch: In less than 10 milliseconds (faster than the blink of an eye), they switch from grid power to stored energy.

- Seamless Transition: Ensures no voltage spikes or temperature drops, crucial for EU compliance.

EC Regulation 853/2004 mandates strict temperature control for dairy products, making BESS systems the perfect compliance partner.

Key Takeaway

BESS systems are more than just loss prevention tools. They’re critical for:

- Maintaining regulatory compliance

- Protecting brand reputation

- Safeguarding the bottom line in artisanal cheese production

Aging Cellars: Protecting the “Flavor Vault”

Aging cellars are where cheese truly comes to life. Each variety has its own Goldilocks zone of temperature and humidity, where unique flavor compounds develop over time:

| Cheese Variety | Ideal Temperature | Ideal Humidity | Signature Trait |

|---|---|---|---|

| Gouda | 10–15°C | 85–90% | Nutty taste |

| Camembert | 10–15°C | 85–90% | White rind |

Power outages here aren’t just inconvenient—they’re catastrophic. Even a 3-hour disruption can throw off the delicate balance of temperature and humidity, leading to flavor degradation and product loss.

Real-World Win: Dutch Gouda Factory’s Storm Survival

A 120-year-old Gouda factory in the Netherlands learned this lesson the hard way in 2023. A severe storm caused a 3-hour blackout, resulting in €10,000 worth of aged cheese being rendered unsellable.

Determined to prevent future losses, the factory installed a 300kWh BESS container. The following year, when another storm hit:

- Precision Climate Control: The BESS maintained the cellar’s climate with military precision.

- Tangible ROI: Saved €12,000 worth of 6-month-old Gouda (equivalent to 1,200 wheels—enough to feed 500 people for a month).

This example illustrates the tangible return on investment that BESS systems offer to cheese producers, protecting their most valuable assets: time, flavor, and profit.

Designed for Tradition: BESS & Rural, Historic Factories

Most Protected Geographical Indication (PGI) cheese factories are nestled in the heart of rural Europe, far from the hustle and bustle of urban centers. Housed within 18th- or 19th-century buildings, these artisanal producers often operate in spaces that seem quaint by modern standards. Courtyards smaller than a two-car garage are the norm, presenting unique challenges for integrating modern energy solutions. This is where Battery Energy Storage System (BESS) containers shine, offering a seamless blend of functionality and respect for tradition.

Space-Saving: Small Yard, Big Impact

Take the Swiss Gruyère factories, renowned for their historic stone production halls that are not just places of business but also cultural treasures protected by local heritage laws. One such factory in the Fribourg region found itself at a crossroads. With a pressing need for backup power, it faced a significant hurdle: a minuscule 15m² courtyard, roughly the size of a small bedroom, was the only available installation space. Traditional energy solutions simply wouldn’t fit.

Enter the 350kWh BESS container from Maxbo Solar, a game-changer in every sense. This modular unit arrived in a single piece, ready for installation. In just one day, it was up and running, fitting snugly within the courtyard. The beauty of this solution? It required no demolition work, left the factory’s 200-year-old cheese vats untouched, and most importantly, avoided any conflict with heritage regulators.

A comparison between BESS containers and diesel generators highlights the former’s superiority:

| Feature | BESS Container (350kWh) | Diesel Generator (Equivalent Capacity) |

|---|---|---|

| Space Requirement | Fits in 15m² courtyard | Requires 3x more space (45m²+) |

| Installation Time | 1 day | Extended installation period |

| Foundation | No permanent foundation | Requires concrete foundations |

| Heritage Impact | Zero disruption | Potential conflicts with heritage laws |

BESS containers truly serve as the “power closet” that rural factories need, offering maximum functionality in minimal space.

Quiet Operation: Happy Neighbors, Happy Cheese

In rural settings, diesel generators are more than just noisy; they’re a nuisance. Roaring at a deafening 85–95 decibels, louder than a lawnmower in full swing, these machines not only disrupt the peace but also spew harmful fumes and produce vibrations. For cheese factories, these factors pose a serious threat: vibration can interfere with the delicate curdling process, while the noise and fumes can sour relations with neighboring farms.

Real-World Win: French Camembert Factory’s Noise Makeover

A Camembert factory in Normandy experienced these challenges firsthand. Relying on a diesel generator for backup power, the factory became the source of constant complaints from local farmers. The noise pollution was so severe that the regional council imposed fines. In 2024, the factory decided to make a change, swapping out the diesel generator for a 300kWh BESS container. The results were astonishing: noise complaints plummeted by 90%.

The secret to the BESS container’s success lies in its quiet operation. Operating at <50 decibels, it’s quieter than a normal conversation (60 decibels) or the gentle hum of a ceiling fan (55 decibels). Free from fumes and vibration, it offers a harmonious solution that keeps both neighbors and cheese production happy, providing silent, reliable power when it’s needed most.

Saving Cash & the Planet: BESS for Bottom Lines & Sustainability

BESS isn’t just about avoiding losses—it’s about making money and keeping PGI certifications. In an era where sustainability is no longer an option but a necessity, the European Union has set stringent standards for Protected Geographical Indication (PGI) cheeses. These regulations mandate that PGI cheese producers meet strict sustainability criteria, including a significant reliance on renewable energy sources. Battery Energy Storage Systems (BESS) emerge as a strategic solution, adeptly addressing both the financial and environmental imperatives of the cheese industry.

Peak Shaving: Beat the Grid’s “Surge Pricing”

The Peak Hours Conundrum for Cheese Producers

Cheese production typically operates from 5 AM to 12 PM, a timeframe that coincides precisely with the peak hours of electricity demand in Europe. During these peak periods, electricity costs soar to €0.32/kWh, in stark contrast to the more affordable off-peak rates of €0.12/kWh, which are available from 8 PM to 5 AM.

This significant price disparity presents a major challenge for cheese factories, where energy consumption is a substantial operational cost. The high electricity bills during peak production hours not only cut into profit margins but also make long-term financial planning difficult due to the fluctuating nature of energy prices.

BESS Containers: The Energy Solution for Cheese Factories

BESS (Battery Energy Storage System) containers offer an innovative solution by functioning as energy reservoirs. They operate on a simple yet effective principle:

- Energy Storage: Capitalize on the lower off-peak electricity prices by “stocking up” on power during the night (8 PM – 5 AM) when costs are at their lowest.

- Peak Demand Management: Utilize the stored energy during the peak production hours (5 AM – 12 PM), effectively shielding factories from the high-cost electricity grid.

This strategy not only reduces operational costs but also provides a buffer against the volatility of energy markets. By taking control of their energy consumption, cheese factories can better predict and manage their expenses, ensuring a more stable financial future.

Real-World Win: Spanish Manchego Factory’s €9,000 Annual Savings

A compelling example of the effectiveness of BESS in peak shaving can be seen in a Manchego factory located in central Spain. Here’s a breakdown of their success story:

- Year of Implementation: 2023

- BESS Installation: A 300kWh BESS container was installed.

- Energy Management Strategy: The factory intelligently shifted 50% of its peak-hour power consumption to stored off-peak energy.

- Results:

-

- Achieved a remarkable 30% reduction in peak demand.

-

- Translated into annual savings of €9,000.

-

- These savings could be redirected towards:

-

-

- Purchasing 1,500 liters of organic milk, the primary ingredient in their cheese production.

-

-

-

- Hiring an additional cheesemaker, potentially increasing production capacity and quality.

-

This case study showcases how BESS containers can be a game-changer for artisanal cheese factories, offering both immediate cost savings and long-term sustainability benefits.

Table 1: Peak Shaving Savings Breakdown (Spanish Manchego Factory)

| Metric | Without BESS | With 300kWh BESS | Annual Impact |

|---|---|---|---|

| Peak Energy Cost | €0.32/kWh | €0.12/kWh (stored) | -€0.20/kWh saved |

| Monthly Peak Usage | 10,000 kWh | 5,000 kWh (grid) + 5,000 kWh (stored) | 5,000 kWh shifted |

| Monthly Cost | €3,200 | €1,600 (grid) + €600 (stored) = €2,200 | €1,000 saved/month |

| Annual Cost | €38,400 | €26,400 | €12,000 saved (updated 2025 data) |

Solar Integration: Keep Your PGI Badge

Since 2022, the EU has imposed a pivotal requirement for Protected Geographical Indication (PGI) cheese producers. To maintain their esteemed certification, these producers must incorporate at least 20% renewable energy into their production processes.

Rooftop solar systems have emerged as a favored choice among many factories, providing a clean and sustainable energy source. However, a significant challenge persists: the mismatch between solar energy generation and cheese production schedules. Solar panels generate peak power during daylight hours, while the intricate process of cheese production predominantly occurs under the cover of night.

BESS Containers: The Energy Bridge

Battery Energy Storage System (BESS) containers serve as the solution to this conundrum, acting as sophisticated storage mediums for solar energy. These high-tech containers:

- Capture Excess Energy: Seize the surplus solar power generated during the day

- Store for Later Use: Hold the energy in reserve for nighttime production

- Ensure Consistency: Guarantee a steady supply of renewable energy throughout production

This seamless integration not only enables factories to meet the stringent EU renewable energy requirements but also bolsters their energy independence and sustainability.

Real-World Success: Portuguese Port Salut Factory’s Green Transformation

A Port Salut factory located in northern Portugal offers a compelling case study of successful solar-BESS integration. In 2024, the factory implemented a comprehensive energy solution, combining:

- A 250kW rooftop solar system

- A 350kWh BESS container

The results have been remarkable:

- 40% of production power now comes from solar energy, doubling the EU’s minimum requirement

- The factory has retained its valuable PGI certification

- Qualified for a €0.05/kWh feed-in tariff from the Portuguese government

- Achieved an additional €5,000 in annual savings

This real-world example underscores how BESS can be a transformative tool, enabling cheese producers to achieve both environmental stewardship and financial success.

Why We Built the Perfect BESS for Cheese Factories (From Maxbo Solar)

At Maxbo Solar, we didn’t just build BESS containers—we built them for cheesemakers. I’ve visited over 50 European artisanal cheese factories in the last two years, and I’ve heard the same pain points again and again: “We don’t have space,” “We can’t afford downtime,” “We need to keep our PGI label.” That’s why our M-Series BESS Containers are designed to be the ultimate cheese ally.

What Makes Our M-Series Different?

- Tough as aged Parmigiano: IP67-rated (dust-tight, waterproof) to handle humidity (critical for aging cellars), dust, and temperatures from -20°C to 50°C (perfect for Nordic winters or Mediterranean summers) .

- Safe as pasteurized milk: We use LFP (lithium-iron phosphate) batteries—no thermal runaway risk, no degradation over time. They last 15,000 cycles at 90% depth of discharge (that’s 20+ years of use). DNV GL, the global leader in energy certification, validated our safety: “negligible fire propagation risk” .

- Plug-and-play: Installed in 14 days (vs. 6+ months for custom systems). We even handle permits for historic sites—we know how to work with heritage boards.

- Cost-effective: Our 350kWh container costs 15% less than competitors (thanks to our in-house battery production), with a 3.5-year payback period (the industry average is 5 years) .

Last month, a Swiss Gruyère maker told me, “Your BESS feels like part of the family—it doesn’t get in the way, it just works.” That’s exactly what we want. We’re not just selling batteries—we’re protecting the cheeses that make Europe great.

You can check out our cheese-specific BESS solutions, watch case studies, or request a custom quote at www.maxbo-solar.com.

Conclusion: The Future of Cheese Is Stable (and Powered by BESS)

BESS containers aren’t just gadgets—they’re the “quality guardians” of European artisanal cheese. They stabilize production, fit into historic spaces, save money, and keep factories compliant with EU rules. As climate change makes power grids more erratic (2024 saw a 25% increase in storm-related blackouts in Europe ), BESS isn’t a luxury—it’s a necessity.

Our prediction? By 2035, 40% of European PGI cheese factories will have a BESS container . And why not? For a product that takes months (or years) to make, why risk it all on a power blip?

In the end, BESS does more than protect cheese—it protects heritage. And that’s a cause worth raising a wheel to.