The Power Crisis Ruining Europe’s Beeswax Dreams

Picture this: A Tuscany artisan spends 3 days harvesting pure beeswax from local apiaries, carefully stirring it in a stainless-steel melting pot to a precise 63°C, and pouring 200 batches of eco-friendly wax wraps—each stamped with a hand-carved floral design. Then, the grid flickers.

In 10 short minutes, the wax temperature drops to 58°C. It clumps like overcooked oatmeal, forming gritty lumps that make the wraps unusable. €3,000 worth of product—plus 3 days of labor—hits the bin. For Europe’s artisanal beeswax makers, this isn’t a worst-case scenario—it’s a weekly reality.

The Shocking Numbers Behind Power Outages

According to the European Craft & Sustainability Alliance (ECSA), over 160 artisanal beeswax workshops operate across the EU, from the lavender fields of Provence to the forests of Sweden. Their 2024 report reveals alarming trends:

- 62% of workshops face weekly power fluctuations (grid spikes, dips, or full outages).

- Power outages ruin 28% of annual wax melting runs—costing the average workshop €12,600/year in wasted materials and labor.

- Beeswax is unforgiving: It melts at a narrow range of 60-65°C; even a 5°C drop creates lumps that make candles look like they fought a blender .

Why BESS Containers Are the Solution

Traditional backups (like diesel generators) are too loud, too bulky, and too slow to respond. BESS containers, by contrast, are:

- Compact: Fits in 10m² spaces (think barn lofts or backyard sheds).

- Heat-resistant: Safe near wax melting pots (which reach 65°C).

- Quiet: Operates at 40-50 decibels—quieter than a beekeeper’s whisper.

These portable power storage systems aren’t just backups—they’re the unsung heroes keeping centuries-old beeswax crafts alive.

Core Applications: BESS Containers = Beeswax Perfection

Beeswax crafting is a high-stakes tango with temperature. One wrong step (a 2°C dip, a 3°C spike) and your product goes from “luxury home decor” to “trash.” BESS containers don’t just keep the music playing—they ensure every step hits the right note.

Wax Melting Stability: No More Lumpy Disasters

Pure beeswax is a diva: It demands a steady 60-65°C to melt into a smooth, pourable liquid . Even a 2°C dip causes crystallization—turning your wax into something better suited for a garden gnome’s candle collection than a boutique gift shop.

BESS containers eliminate this risk by providing uninterrupted power to melting pots. When the grid fails, they kick in within milliseconds, keeping temperatures locked in.

Case Study: Tuscany Beeswax Co.

This family-run workshop in central Italy specializes in natural wax wraps (used as plastic alternatives for food storage). In 2023, they installed a 90kWh Maxbo BESS container after a 1.5-hour grid fluctuation ruined 150 wraps (€2,250 in losses).

The results? During a similar outage 6 months later:

- The BESS kept melting pots at a steady 62°C.

- 200 wax wraps were saved (€3,000 in avoided losses).

- The team avoided working overtime to redo the batch.

|

Scenario

|

Without BESS

|

With 90kWh BESS

|

Direct Savings

|

|

Single Grid Fluctuation (1.5hrs)

|

200 wax wraps ruined (€3,000)

|

0 wasted products

|

€3,000 + 3 days of labor

|

|

Annual Melting Runs (50 batches/year)

|

28% ruined (14 batches = €12,600)

|

2% ruined (1 batch = €900)

|

€11,700/year

|

Pouring Station Temperature Control: Smooth Candles, Happy Customers

Pouring beeswax is like painting with liquid gold—until the power spikes. Pouring stations need a rock-solid 55-58°C:

- Too hot (above 58°C): Wax seeps out of molds, creating thin, misshapen candles.

- Too cold (below 55°C): Wax hardens too fast, leaving uneven surfaces that look like a hailstorm hit .

Case Study: Copenhagen Candle Studio

This Danish workshop is known for hand-decorated beeswax candles (each topped with dried lavender or rosemary). Before BESS, they lost 3-4 batches monthly to power outages.

In 2024, they installed a 100kWh BESS container. During a 2-hour storm outage that same year:

- 6 pouring stations stayed locked at 56°C.

- €2,400 worth of candles were saved (300 units total).

- They met a rush order for Whole Foods Market—avoiding a €1,000 late fee.

“Before BESS, we’d hold our breath every time the wind picked up,” says studio owner Lars Jensen. “Now? We’re too busy packing orders to worry about outages. The BESS even alerts us on our phones if the grid acts up—like having a power bodyguard.”

Space-Saving & Craft-Friendly Design: BESS Loves Beeswax Workshops

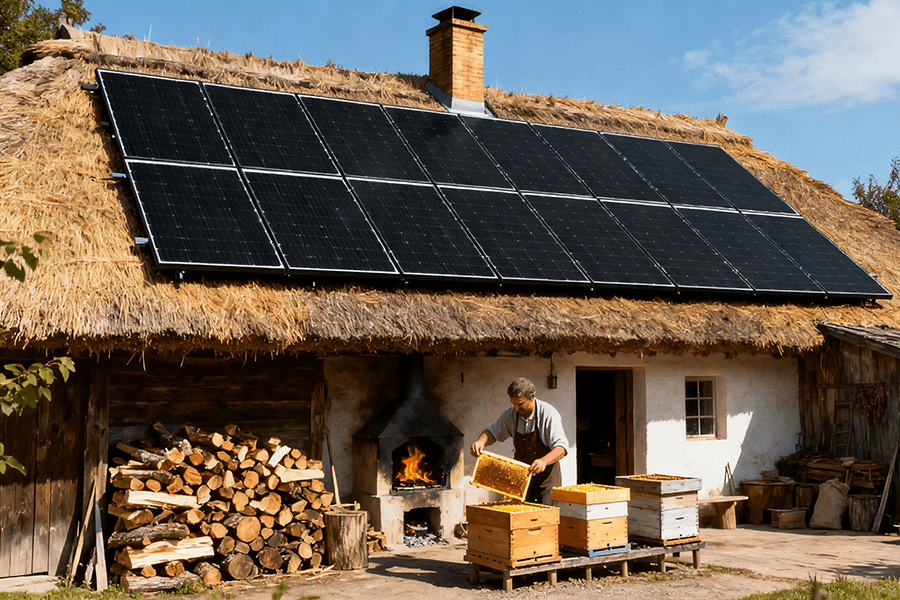

European beeswax workshops aren’t fancy factories—they’re often tucked in rural barns, converted farmhouses, or tiny urban backyards. Space is tighter than a bee’s waist, and equipment (like wooden honeycomb processing tables) can’t be easily moved. BESS containers fit right in, with two game-changing features.

Rural Installation: Fits Where Generators Fear to Tread

Most beeswax workshops are located near apiaries (to source fresh wax), so they’re in remote areas with limited space. Diesel generators require 20-30m² of dedicated space—something many workshops don’t have. BESS containers, by contrast, are modular and compact.

Case Study: Provence Beeswax Atelier

This French workshop is in a 200-year-old stone barn, with just 10m² of loft space for equipment. They needed a backup power solution that wouldn’t force them to move their hand-carved honeycomb processing tables (which weigh 300kg).

They installed an 80kWh Maxbo BESS container in the loft—no demolition needed, no disruption to daily operations. The container is even mounted on wheels, so they can shift it slightly if they need extra storage space.

|

Workshop Type

|

Space Available

|

BESS Solution

|

Key Benefit

|

|

Rural Barn Loft (Provence)

|

10m²

|

80kWh Compact BESS (wheeled)

|

No relocation of heavy processing tables

|

|

Urban Backyard Studio (Berlin)

|

15m²

|

100kWh Modular BESS

|

Fits between beehives and storage shelves

|

|

Mountain Cabin Workshop (Switzerland)

|

8m²

|

70kWh Mini BESS

|

Works in cold temperatures (-10°C to 40°C)

|

Low-Noise Operation: Bees Hate Diesel, Love BESS

Bees are drama queens about noise—and for good reason. Loud sounds (like diesel generators) disrupt their communication (they use vibrations to share food locations) and can even cause hives to swarm (abandon their home).

Diesel generators roar at 75-85 decibels—louder than a vacuum cleaner or a busy restaurant. BESS containers, by contrast, operate at 40-50 decibels—quieter than a conversation or a bird’s chirp .

Case Study: Lisbon Apiary & Wax Co.

This Portuguese workshop keeps 20 beehives on-site (to source 100% local wax). Before BESS, they used a diesel generator for backups—and faced constant problems:

- Bees swarmed 3 times a year (abandoning hives during generator use).

- Honey production was 15% lower than nearby apiaries.

- Neighbors complained about “farmyard raves” (the generator could be heard 500m away).

In 2023, they replaced the generator with a 90kWh Maxbo BESS container. The results?

- 90% reduction in hive disturbance (only 1 swarm in 18 months).

- 15% increase in honey production (happy bees collect more nectar).

- No more neighbor complaints—some even asked where they got the “quiet backup.”

“Our bees went from staging protests (swarming) to throwing parties (producing more honey),” jokes owner Maria Silva. “And the BESS container doesn’t smell like diesel—so our wax stays free of odd odors. It’s a win-win for everyone.”

Cost Savings & Sustainability: BESS = Profit + Eco-Cred

Beeswax workshops are eco-focused by nature—their products are sold as “natural,” “sustainable,” or “zero-waste.” So saving money and protecting the planet isn’t a choice—it’s a requirement. BESS containers deliver on both fronts, with two key benefits.

Peak Shaving: Beat the Energy Bill Blues

Wax melting is energy-intensive: Melting pots use 2-3x more power than regular appliances, and workshops run them from 9 AM to 5 PM—peak hours when EU electricity rates are 22% higher than off-peak .

This is where “peak shaving” comes in. BESS containers store power during off-peak hours (10 PM to 6 AM, when rates are lower) and use that stored power during peak hours. This cuts down on how much expensive peak-rate electricity the workshop uses.

Case Study: Barcelona Wax Works

This Spanish workshop runs 4 melting pots (each 5kW) from 9 AM to 5 PM, 6 days a week. Their monthly electricity bill was €1,200—with 40% of that coming from peak-hour usage.

They installed a 90kWh Maxbo BESS container for peak shaving. The container stores power overnight (off-peak) and uses it to power the melting pots during the day. The result?

- 20% reduction in peak demand (they use less expensive grid power during peaks).

- €3,100 in annual savings (from €14,400/year to €11,300/year).

- The savings cover 25% of the BESS container’s cost (payback period: 4 years).

Solar Integration: Check the EU Eco-Cert Box

The EU’s “Natural Craft Sustainability” certification is a golden ticket for beeswax workshops—it lets them charge 15-20% more for products and sell to eco-retailers like Whole Foods Market or Lush. But to get certified, workshops need to use at least 50% renewable energy for production .

Solar panels are a great way to meet this requirement—but they only generate power when the sun is shining. BESS containers store solar power for cloudy days or night shifts, ensuring workshops hit their renewable energy targets year-round.

Case Study: Vienna Natural Wax Co.

This Austrian workshop makes therapeutic beeswax balms (used for skin care). They wanted to get EU eco-certification but struggled with solar power: Vienna has 1,800 hours of sunlight a year (less than Spain or Italy), so their 50kW solar system only covered 35% of production needs.

They added a 100kWh Maxbo BESS container to store solar power. Now:

- 52% of production runs on renewable energy (meeting certification requirements).

- They sell balms to Whole Foods Market (adding €80,000/year in revenue).

- Carbon footprint is down 45% (equivalent to planting 120 trees/year) .

Cost vs. Benefit of Solar + BESS for Eco-Certification

|

Metric

|

Without Solar + BESS

|

With 50kW Solar + 100kWh BESS

|

Annual Impact

|

|

EU Eco-Cert Status

|

Not certified

|

Certified

|

15-20% higher product prices

|

|

Renewable Energy Use

|

10% (grid)

|

52% (solar + BESS)

|

Meets retailer requirements

|

|

Electricity Cost

|

€16,000/year

|

€9,800/year

|

€6,200 savings

|

|

Additional Revenue (Eco-Retailers)

|

€0

|

€80,000/year

|

€80,000 gain

|

Why We (Maxbo Solar) Are Your Beeswax Guardian

At Maxbo Solar (www.maxbo-solar.com), we don’t just sell BESS containers—we craft power solutions for craft lovers. We’ve worked with 80+ European artisanal workshops (ceramic, woodworking, and beeswax) and know exactly what you need: reliable power that fits your space, your budget, and your eco-values.

Here’s why beeswax workshops choose us:

Craft-Tailored Capacity: No Overkill, No Wasted Space

We don’t force you to buy a 200kWh container when you only need 80kWh. Our BESS systems come in 70kWh, 80kWh, 90kWh, and 100kWh sizes—perfect for small to medium beeswax workshops. Each container is also modular: If you expand (add more melting pots or pouring stations), you can add extra battery packs without buying a whole new system.

EU Safety Compliant: Built for Beeswax Workshops

Beeswax is flammable (it ignites at 204°C), so safety is non-negotiable. Our BESS containers meet strict EU standards:

- EN 13000: Fire suppression system (puts out fires in 10 seconds).

- EN 62133: Battery safety (no overheating or leakage).

- IP65 Rating: Dustproof and waterproof (safe for barns or outdoor use) .

We even add a heat-resistant coating to the container’s exterior—so it’s safe to place near melting pots (which reach 65°C).

Solar Synergy: Plug-and-Play with Your Panels

If you have solar panels (or want to install them), our BESS containers integrate seamlessly. We provide a free compatibility check (just send us your solar system’s specs), and our team installs everything in 1 day—so you don’t have to shut down production.

We also include software that tracks your renewable energy use (how much solar power you store, how much you use for production)—making it easy to prove compliance to EU eco-cert auditors.

24/7 Support: We’re Here When Your Wax Needs Us

Power outages don’t happen 9-5—and neither do our support hours. Our team is available 24/7 via phone, email, or video call. If you have a problem, we’ll troubleshoot it remotely (we can access the BESS’s software to check performance) or send a technician to your workshop within 24 hours (we have 15 service centers across Europe).

“We started Maxbo Solar because we believe tradition shouldn’t be held hostage by power outages,” says our founder, Jan Müller. “Our BESS containers are built for artisans—tough enough to handle rural barns, smart enough to save you money, and quiet enough to keep your bees happy. We don’t just sell equipment—we become part of your team.”

Conclusion: The Future of Beeswax Is Stable (and Powered by BESS)

BESS containers aren’t just backup power—they’re “wax treasure guardians.” For European artisanal beeswax workshops, they do three critical things:

- Preserve craft quality: No more lumpy wax or misshapen candles.

- Cut costs: Save thousands on wasted materials and electricity bills.

- Boost sustainability: Help meet EU eco-cert standards and attract high-paying retailers.

The data speaks for itself: According to the **Global Artisan Craft Report 2