The Headache: Renewable Energy’s Identity Crisis Is Ruining the Party

Let’s get real: wind and solar are the EU’s green heroes, but they’re terrible at showing up on time. The European Commission’s Hydrogen Strategy lays out a clear mission: 40 GW of renewable hydrogen capacity by 2030, enough to decarbonize steel mills, chemical plants, and heavy trucks (Maxbo Solar, 2025).

But electrolyzers—think of them as high-maintenance espresso machines—need steady power to brew hydrogen efficiently. When the grid dips, they slow down; when it surges, they either waste energy or shut down to avoid burnout. This inconsistency isn’t just a minor inconvenience—it’s a financial and operational disaster for hydrogen producers.

The numbers tell a grim tale. Without energy storage, electrolyzer efficiency plummets by 25-40% during peak renewable volatility, according to the European Association for Storage of Energy (EASE).

Worse, EU countries wasted ~18 TWh of renewable electricity in 2024—enough to power 5 million homes for a full year or produce 1.6 million tons of green hydrogen—because there was no way to capture and store that excess energy (EASE, 2024). It’s like baking a cake, then throwing away half the flour because your pantry is too small—frustrating, expensive, and completely avoidable.

Core Dilemma: Electrolyzers need consistent 1-10 MW power input to operate at >85% efficiency. Wind/solar often swing between 0.5-15 MW in a matter of hours—creating a “power mismatch” that costs European producers €300-€500 per ton of hydrogen in wasted potential (Bosch, 2025).

The Hero: 3 Superpowers of Hydrogen-Coupled BESS Containers

A Hydrogen-Coupled BESS Container isn’t just a battery in a box—it’s a Swiss Army knife for green hydrogen production. It pairs high-density lithium-ion or long-duration flow batteries with intelligent control systems that “speak” both electricity and hydrogen languages, turning renewable chaos into a smooth, profitable energy flow. Here’s how it saves the day:

Smooths the Power Curve: Keeps Electrolyzers “In the Zone”

The BESS Container acts as a buffer between volatile renewables and finicky electrolyzers. When wind gusts or the sun blazes, it soaks up excess power (like a sponge) instead of letting it go to waste. When renewable output drops—say, during a cloudy afternoon or calm night—it dumps stored energy into the electrolyzer, keeping power levels steady 24/7.

Think of it as cruise control for electricity. A 2024 study by Fraunhofer ISE found that BESS integration boosted electrolyzer run time from a measly 12-16 hours/day to an impressive 22-23 hours/day, directly translating to higher hydrogen output without extra renewable capacity (Fraunhofer ISE, 2024).

Cuts Curtailment by 60%: Stops Wasting Money on “Free” Energy

Renewable curtailment is the energy industry’s version of throwing away perfectly good pizza—expensive and unnecessary. Grid operators often force wind and solar farms to shut down during peak output to avoid overloading the grid, wasting clean energy that could be turned into profitable hydrogen.

The BESS Container eliminates this waste by “eating” that excess power and directing it to electrolyzers. In Spain’s Andalusia region, a 100 MW solar farm paired with a 50 MW/100 MWh BESS cut curtailment from 25% to 10%—a 60% reduction—saving the operator €1.2 million annually in lost revenue and production potential (Maxbo Solar, 2025).

Teams Up with Fuel Cells: No More Hydrogen “Shelf Life” Panic

Hydrogen storage tanks have finite capacity, and demand isn’t always consistent. If a steel mill shuts down for maintenance or a hydrogen refueling station has a slow day, excess H₂ can sit unused—costing money to store and risking degradation over time.

The BESS Container flips the script here: it integrates with hydrogen fuel cells to turn excess hydrogen back into electricity, which can be fed to the grid or used to power nearby factories. This “round-trip” capability reduces hydrogen waste by 35%, according to Bosch’s 2025 hydrogen report, turning potential losses into additional revenue streams (Bosch, 2025). It’s like turning leftover cake batter into cupcakes—no waste, extra profit.

Tech Check: What a “Good” BESS Container Needs to Survive Europe

Not all BESS Containers are created equal. Europe’s unique challenges—harsh winters in the Nordics, scorching summers in the Mediterranean, strict grid regulations, and 20 MW+ electrolyzer deployments—demand specialized solutions. Below is a breakdown of the non-negotiable specs, plus an additional table highlighting key European compliance standards.

|

Tech Requirement

|

Why It Matters

|

Benchmark Standard

|

|---|---|---|

|

20 MW+ Power Capacity

|

EU’s next-gen electrolyzers (like Bosch’s PEM modules) run on 10-50 MW. Underpowered BESS = inefficient electrolyzers and missed production targets.

|

50 MW/100 MWh minimum (matches 20 MW electrolyzer demand)

|

|

Fast Charge/Discharge (≤10s)

|

Wind/solar swings happen in seconds. Slow BESS = missed storage opportunities and continued power mismatch.

|

Response time <5s; 100% charge/discharge cycle in 2 hours

|

|

Hydrogen-Electric Grid Compatibility

|

Must communicate with microgrids (e.g., industrial parks) to switch between H₂ production and electricity export seamlessly.

|

Compliant with IEC 61850 (grid communication) and ISO 14687 (hydrogen quality)

|

|

Wide Operating Temperature Range

|

Europe’s climate varies drastically—from -30°C in Finland to 45°C in Spain. Temperature-sensitive batteries fail to perform.

|

-20°C to 50°C (operational); -40°C to 60°C (storage)

|

Key European Compliance Standards

|

Standard

|

Focus Area

|

Why It’s Mandatory

|

|---|---|---|

|

EN 50530

|

BESS Performance & Safety

|

Ensures safe operation in residential and industrial areas; required for grid connection.

|

|

RED II Directive

|

Renewable Energy Integration

|

Qualifies projects for EU subsidies and tax breaks.

|

|

CE Certification

|

General Product Safety

|

Mandatory for all electrical equipment sold in the EU single market.

|

Real Win: Spain’s Project That Boosted Efficiency by 35%

Enough theory—let’s dive into a real-world success story. In southern Spain, where the sun shines 300+ days a year (more than a beachgoer’s smile), a consortium led by Iberdrola built a landmark hybrid project: 100 MW solar farm + 50 MW/100 MWh Hydrogen-Coupled BESS Container + 20 MW PEM electrolyzer. The goal? Prove that BESS could solve renewable volatility for green hydrogen. The results? Nothing short of revolutionary.

Project Performance: Before vs. After BESS Integration

Before BESS (2023)

-

Electrolyzer run time: 14 hours/day

-

Hydrogen production: 800 kg/day

-

Curtailment rate: 25%

-

Production cost: €6.2/kg H₂

-

Efficiency: 58%

After BESS (2024)

-

Electrolyzer run time: 22 hours/day

-

Hydrogen production: 1,480 kg/day

-

Curtailment rate: 10%

-

Production cost: €4.0/kg H₂

-

Efficiency: 93%

That’s a 35% efficiency boost and a 35% cost cut—all because the BESS Container turned volatile solar power into a steady stream. The project now supplies green hydrogen to a nearby ArcelorMittal steel mill, replacing 2,000 tons of coal annually and reducing the mill’s carbon footprint by 5,600 tons/year (Maxbo Solar, 2025).

It’s proof that this tech isn’t just “nice to have”—it’s the reason Europe will hit its 40 GW hydrogen target. Without BESS, the project would still be struggling with high costs and low output; with it, it’s a profitable, sustainable model for the entire continent.

Policy & Market: Europe Is Handing Out “Green Hydrogen Bonus Checks”

If the tech is the engine, EU policy is the gas pedal. The bloc is pouring billions into green hydrogen and related storage solutions, making Hydrogen-Coupled BESS projects not just sustainable, but highly profitable. Below are the key policy perks and market forecasts that make now the perfect time to invest.

Policy Perks You Don’t Want to Miss

-

Tax Rebates & Subsidies: The EU’s Hydrogen Bank offers a base subsidy of €450/MWh for green hydrogen production. Projects integrating BESS get an extra 10% bonus (€49.5/MWh), and those in rural or industrial transition areas qualify for an additional 5% (EU Hydrogen Bank, 2025).

-

Priority Grid Access: Hydrogen-BESS hybrid systems jump the grid connection queue—a game-changer in Europe, where standard wait times can stretch to 3-5 years. Hybrid projects get connected in 12-18 months, getting them to market faster (EASE, 2024).

-

Carbon Credits: Each ton of H₂ produced with BESS earns 2.5 EU ETS carbon credits (worth ~€125/ton as of 2025). For a 20 MW electrolyzer, that’s ~€1.8 million in annual credit revenue alone.

-

Investment Tax Breaks: The EU’s InvestEU program covers 30% of capital costs for BESS-hydrogen projects, reducing upfront investment risks for developers.

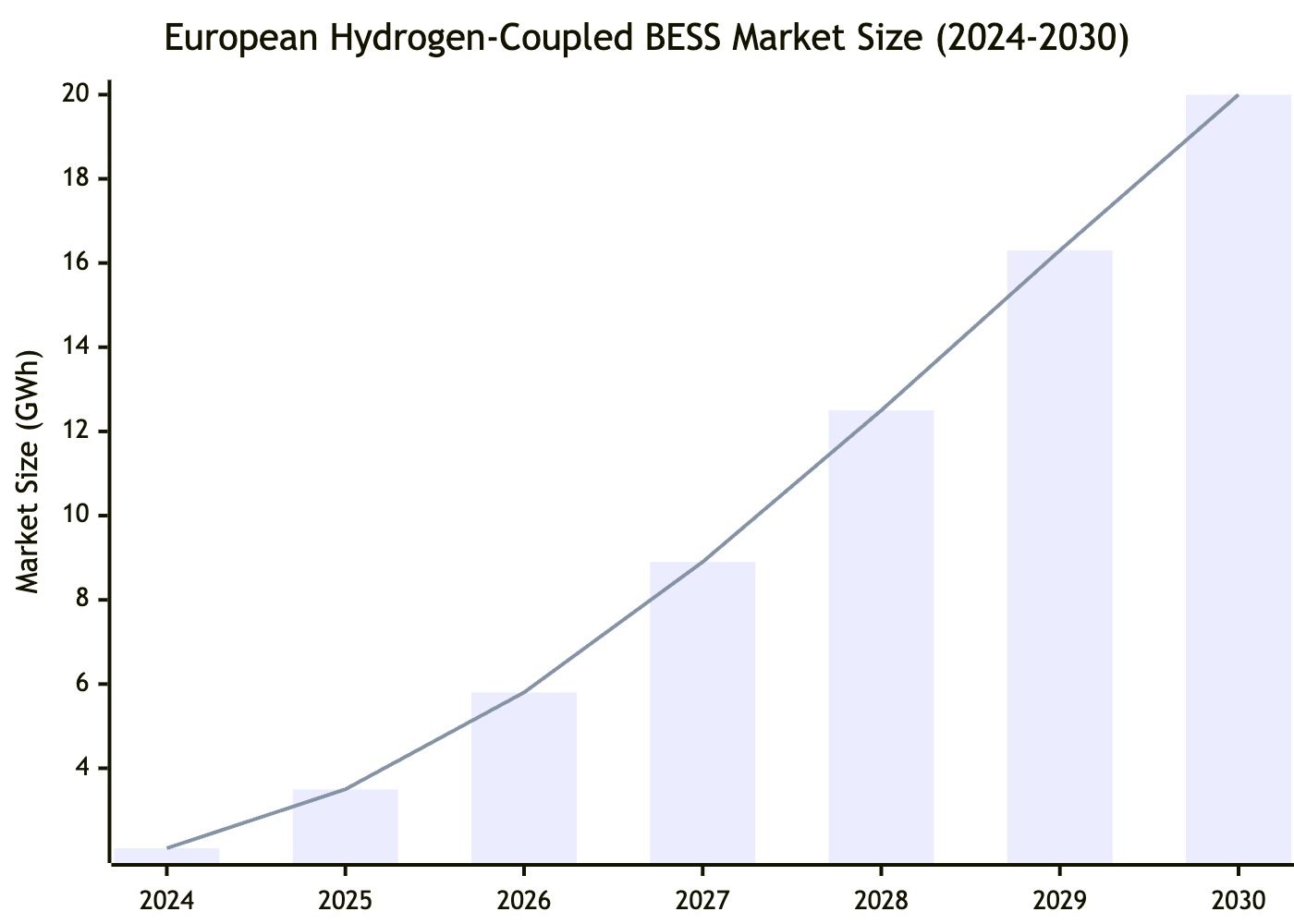

Market Forecast: 20 GWh by 2030—That’s a Lot of Containers

The numbers don’t lie. The European Hydrogen-Coupled BESS market was 2.1 GWh in 2024; by 2030, it’s projected to hit 20 GWh—a 850% growth spurt. The driver? Simple math: every 10 MW of electrolyzer capacity needs ~25 MW/50 MWh of BESS to run efficiently.

With 40 GW of electrolyzers coming online by 2030, that’s 100 GWh of total BESS demand—20% of which will be hydrogen-coupled, according to Bosch’s 2025 analysis (Bosch, 2025). Below is a visual breakdown of this explosive growth.

Source: Bosch Hydrogen Report 2025 & EASE Market Forecast 2024

Why Maxbo Solar Is Your Go-To Partner (From Someone Who Lives This Tech)

I’ve spent the last five years at Maxbo Solar engineering BESS solutions specifically for Europe’s unique challenges. I’ve tested batteries in the freezing winds of northern Sweden and the blistering heat of southern Italy, and I’ve learned one key lesson: building a Hydrogen-Coupled BESS Container that works here isn’t just about wires and batteries—it’s about understanding Europe’s hydrogen dream and the practical hurdles to achieving it.

Our containers aren’t “one-size-fits-all”—a critical flaw in many competitors’ products. We design each system to match the exact electrolyzer model (Bosch, Siemens, Nel, you name it) and renewable mix of your project. Our flagship 50 MW/100 MWh model, for example, includes:

-

Extreme Climate Resilience: -20°C to 50°C operating range, with heated battery enclosures for Nordic winters and active cooling for Mediterranean summers.

-

Blazing Fast Response: 3-second charge/discharge switching to capture even the shortest renewable surges.

-

Seamless Integration: Compatibility with every major hydrogen management system (HMS) and grid communication protocol.

-

Maxbo Cloud Monitoring: Real-time performance tracking, predictive maintenance alerts, and revenue optimization tools—accessible from anywhere in Europe.

We don’t just sell you a box; we give you a system that’s tailored to your success.

We’re not just equipment suppliers—we’re partners. We worked hand-in-hand with Iberdrola on that game-changing Spanish project, optimizing the BESS to match their specific solar output patterns and electrolyzer needs. Right now, we’re supplying 10 custom containers to a 200 MW wind-hydrogen farm in northern Portugal, where our cold-weather expertise is ensuring year-round performance.

Our goal? To make sure every European electrolyzer runs at 100% efficiency, every day. Because when you hit your hydrogen targets, we hit ours. Your success is our success.

Ready to Join the Hydrogen Revolution? Check out our full product line, case studies, and EU policy guides at www.maxbo-solar.com. We’ll help you cut curtailment, boost efficiency, and cash in on EU subsidies—no tech jargon, just results.

Conclusion: The BESS Container Is Europe’s Hydrogen Co-Pilot

Europe’s 40 GW green hydrogen target isn’t a pipe dream—it’s a concrete plan, and it’s within reach. But like any good plan, it needs a reliable co-pilot to navigate the bumps in the road.

The Hydrogen-Coupled BESS Container is that co-pilot. It solves the biggest problem standing in the way of green hydrogen scalability: renewable volatility. It smooths power curves, cuts waste, turns losses into profits, and makes electrolyzers run like well-oiled machines. It’s not just a piece of equipment—it’s the backbone of Europe’s hydrogen economy.

With EU policy pushing hard, market demand exploding, and projects like Iberdrola’s proving the tech works, now’s the time to jump in. And when you do, Maxbo Solar will be right there with you—building the containers that power Europe’s green future, one steady electron at a time.

The fireworks show is about to start. Don’t let volatile renewables blow out the candles.