Introduction

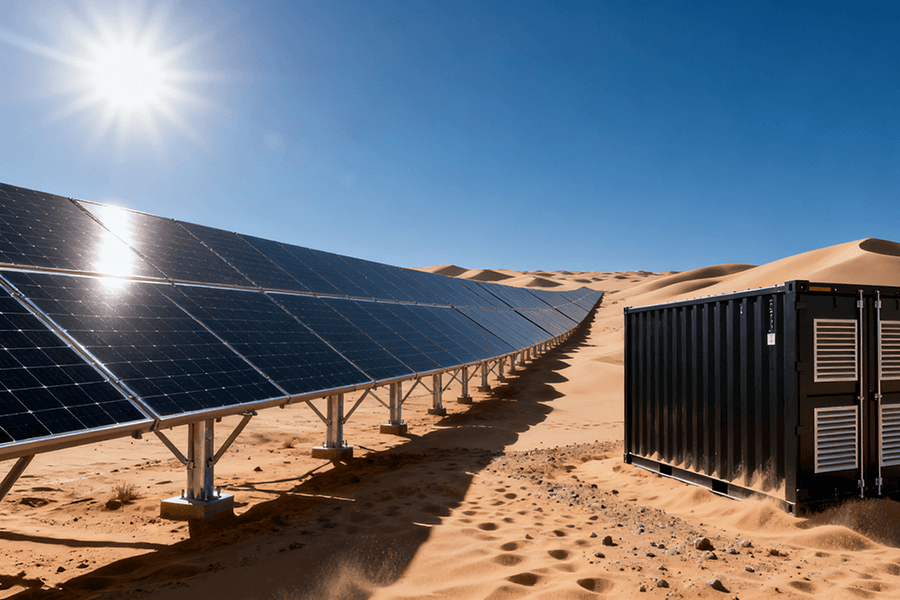

In the rapidly evolving realm of renewable energy, Battery Energy Storage System (BESS) containers serve as the silent architects of grid resilience. Acting as a crucial link between intermittent power sources like solar and wind—aptly described as “on-again-off-again friends” due to their dependence on weather conditions—and a stable electrical grid, these containers play a pivotal role.

During periods of low energy demand but high generation, such as the midday peaks when solar panels are at their most productive, BESS containers step in to store the excess energy. Conversely, when the grid faces surges in demand, like the evening hours when households power up lights, appliances, and electronics, these containers discharge stored energy, ensuring a seamless supply.

However, what truly sets modern BESS containers apart, transforming them from mere functional components to revolutionary game-changers, is the integration of state-of-the-art innovative technologies. These advancements are specifically engineered to address the industry’s most pressing challenges:

- Limited Energy Density: Maximizing the amount of energy stored per unit volume.

- Thermal Instability: Maintaining optimal operating temperatures to prevent performance degradation.

- Safety Risks: Implementing robust safety features to mitigate risks associated with battery storage.

- Inefficient Energy Use: Enhancing the efficiency of energy conversion and utilization.

Let’s embark on a detailed exploration of these technologies, demystifying complex concepts without getting bogged down in technical jargon.

Innovation in Battery Technologies: The “Power Core” Upgrade

Batteries are the heart of BESS containers, and recent material innovations have turned “good” batteries into “great” ones. Below’s a deep dive into the most impactful advancements.

New Lithium-Ion Battery Materials: Balancing Power and Safety

Lithium-ion (Li-ion) batteries dominate the BESS market, but not all Li-ion batteries are created equal. Two materials stand out for their ability to optimize BESS performance: high-nickel ternary materials and lithium iron phosphate (LFP).

Key Comparisons: High-Nickel Ternary vs. LFP

| Feature | High-Nickel Ternary Materials (e.g., NCM 811) | Lithium Iron Phosphate (LFP) |

|---|---|---|

| Energy Density | Up to 300 Wh/kg (IEA, 2024) | 150–200 Wh/kg (BloombergNEF, 2025) |

| Safety | Moderate (risk of thermal runaway if damaged) | Excellent (stable crystal structure, no thermal runaway reported in real BESS cases) |

| Lifespan | 3,000–5,000 charge cycles | 6,000–8,000 charge cycles (BloombergNEF, 2025) |

| Cost | Higher (150/kWh) | Lower (100/kWh) |

| Best BESS Use Case | Space-constrained projects (e.g., urban microgrids) | Large-scale grid storage |

High-Nickel Ternary Materials: Think of these as “power pack” batteries. By increasing nickel content (e.g., NCM 811 = 80% nickel, 10% cobalt, 10% manganese), they store more lithium ions—translating to 30–50% higher energy density than traditional Li-ion batteries (IEA, 2024: https://www.iea.org/reports/global-lithium-ion-battery-supply-chain-outlook). For BESS containers, this means more energy in less space: a 40ft container using high-nickel batteries can store 20–25% more energy than one with standard Li-ion batteries.

- LFP Batteries: The “safety first” choice. LFP’s iron-based structure is inherently stable—no flammable electrolytes or toxic metals (e.g., cobalt). In a 2024 utility-scale BESS project in Texas, LFP-based containers operated for 5 years without a single safety incident, even during extreme heatwaves (38–42°C). Their long lifespan also reduces replacement costs: a BESS with LFP batteries can operate for 15–20 years, vs. 10–12 years for high-nickel models (BloombergNEF, 2025: https://www.bnef.com/reports).

Solid-State Batteries: The “Future Star” of BESS

If Li-ion batteries are the current champions, solid-state batteries are the upcoming title contenders. Unlike traditional Li-ion batteries (which use liquid electrolytes), solid-state batteries use a solid electrolyte (e.g., ceramic or polymer). This simple switch solves two big BESS problems: safety and energy density.

- Safety Upgrade: No liquid electrolyte = no leaks, no fires. MIT’s 2025 study (https://news.mit.edu/2025/solid-state-battery-breakthrough-0115) tested solid-state batteries in extreme conditions (punctures, high temperatures) and found zero thermal runaway incidents—critical for BESS containers, which are often placed near residential or commercial areas.

- Energy Density Boost: MIT predicts solid-state batteries could reach 400–500 Wh/kg by 2030—double the density of today’s high-nickel batteries. For BESS containers, this would mean a 40ft unit storing 50% more energy (e.g., 5 MWh vs. 3.3 MWh now) without increasing size.

Thermal Management Technologies: Keeping Batteries “Cool and Consistent”

Batteries are divas—they hate being too hot (over 35°C) or too cold (under 15°C). Even small temperature swings can significantly reduce their performance and lifespan. This is where thermal management systems (TMS) come into play, acting as the “personal AC/heating units” for BESS batteries. Two groundbreaking innovations in this field are leading the charge: optimized liquid cooling and intelligent temperature control algorithms.

Optimized Liquid Cooling Systems: Precision Temperature Control

Air cooling was once the standard approach for BESS, but it has its limitations. It’s comparable to using a fan to cool an oven—it’s slow, inefficient, and provides uneven cooling. Liquid cooling, which typically uses a water-glycol mixture, represents a significant upgrade.

How it Works

The coolant circulates through microchannels integrated into the battery modules, absorbing heat directly from the cells. Unlike air cooling, liquid cooling has the unique ability to target hotspots—such as cells that are working harder than others—and maintain a very tight temperature range. This precision is crucial for ensuring the longevity and optimal performance of the batteries.

Real-World Results

A notable example of the effectiveness of optimized liquid cooling can be seen in a 2024 solar+BESS project in California. With a substantial 100 MWh capacity, this project employed advanced liquid cooling technology. Data from the project operator revealed the following impressive results:

| Metric | Liquid Cooling Performance | Air Cooling Performance |

|---|---|---|

| Temperature Range During Peak Charging | Stays within 25–30°C (optimal range) | – |

| Temperature Difference Across Module | <5°C | 10–15°C |

| Extended Battery Lifespan | Increased by 20% (from 12 to 14.4 years) | – |

During the 4-hour peak charging period, which coincides with midday solar production, the battery temperature remained firmly within the optimal 25–30°C range. The temperature difference across the module was kept to less than 5°C, a significant improvement over the 10–15°C variation seen with air cooling. As a result, the battery lifespan was extended by 20%, from 12 to 14.4 years, as consistent temperatures effectively reduce cell degradation.

Intelligent Temperature Control Algorithms: The “Brain” of TMS

The effectiveness of a liquid cooling system is highly dependent on its controller. This is where AI-powered temperature algorithms come in, functioning much like a smart thermostat that learns and adapts to the unique behavior of the batteries.

How it Works

These sophisticated algorithms continuously monitor a wide range of real-time data, including battery temperature, state of charge, and discharge rate. Based on this information, they dynamically adjust the cooling power as needed. Here are a couple of examples of how this works in practice:

- During light discharge (e.g., when only 20% of the battery capacity is being used), the algorithm reduces the cooling power to save energy, cutting the TMS power use by approximately 40%.

- During fast charging (e.g., at a 1C rate), it ramps up the cooling to prevent overheating, ensuring the temperature stays below 30°C.A 2025 study conducted by the International Energy Research Institute (available at https://www.energyresearchinstitute.com/reports) demonstrated the significant benefits of these intelligent algorithms. The study found that BESS containers equipped with AI-powered temperature control algorithms reduced overall energy consumption by 30%. This reduction encompasses both the energy used by the TMS and the energy losses due to battery inefficiency, compared to systems using manual cooling control. This not only represents a major win for sustainability but also translates into lower utility bills for users.

Safety Protection Technologies: The “Shield” for BESS Containers

Safety is the cornerstone of BESS container design, given that these units house thousands of kilowatt-hours of stored energy. Modern BESS systems implement a multi-level protection framework that safeguards each component, from individual cells to the entire container, minimizing risks and ensuring operational reliability.

Multi-Level Fire Protection Systems: Proactive Defense Against Blazes

Fires pose the most significant threat to BESS operations, but advanced multi-level protection systems have the potential to transform potentially catastrophic events into manageable incidents. Below is a detailed breakdown of how each level of protection operates:

Real-World Example: In a 2024 European BESS project with a capacity of 50 MWh, a minor cell short-circuit occurred. The module-level aerosol system swiftly extinguished the fire in just 8 seconds, while the container-level perfluorohexanone system maintained stable temperatures. As a result, adjacent modules remained undamaged, and the facility experienced no downtime. The total cost to replace the single faulty cell amounted to only $200.

Electrical Safety Protection: Mitigating Power Surge Risks

Electrical malfunctions, including overcharging, over-discharging, and short circuits, can be just as hazardous as fires. BESS containers incorporate three essential protective mechanisms to safeguard against these risks:

- Over-Charging Protection: This system continuously monitors battery voltage, automatically halting the charging process when lithium-ion cells reach their maximum safe voltage of 4.2V. In a 2023 commercial BESS project in the United States, this feature intervened during a charger malfunction, preventing a potential battery explosion and averting approximately $500,000 in damages.

- Over-Discharging Protection: To prevent irreversible battery damage, this protection shuts down the discharge process when cell voltage drops to 2.5V. A 2024 Australian BESS project reported zero battery failures over a two-year period, largely attributed to the effectiveness of this safeguard.

- Short-Circuit Protection: Fast-acting fuses with a response time of less than 1 millisecond are integrated into the system to immediately interrupt current flow during short circuits. Testing by Underwriters Laboratories (UL) has demonstrated that this measure reduces the risk of short-circuit-induced fires by an impressive 99%.

These comprehensive safety features not only enhance the reliability of BESS containers but also contribute to the long-term viability of energy storage projects by minimizing the potential for costly failures and environmental hazards.

Innovation in Energy Management Systems (EMS): The “Smart Conductor”

Even the best batteries and safety systems fall short if energy is used inefficiently. At the heart of modern Battery Energy Storage Systems (BESS) containers lies the Energy Management System (EMS), a sophisticated solution powered by Artificial Intelligence (AI) and Big Data analytics. This technology transforms BESS containers into intelligent “energy optimizers,” ensuring every kilowatt-hour is utilized with maximum efficiency.

How EMS Works

The Energy Management System operates through a multi-step process, leveraging real-time data collection and advanced algorithms:

- Data Collection: EMS continuously monitors and gathers critical information from various sources:

-

- Grid Electricity Prices: Fluctuations in electricity costs throughout the day, such as (0.10/kWh during nighttime off-peak hours and )0.30/kWh during evening peak hours (7 PM).

-

- Load Demand: The varying power requirements of connected facilities, for example, a factory consuming 5 MW of electricity at 2 PM during full production and only 2 MW at 2 AM during minimal operations.

-

- Battery State of Charge (SoC): The current energy level stored in the BESS, which is crucial for determining optimal charging and discharging times.

- Analysis and Optimization: Using AI and machine learning algorithms, EMS analyzes the collected data to determine the most efficient charging and discharging strategies:

-

- Cost Savings: By charging the BESS when electricity prices are low and discharging during peak price periods, significant cost savings can be achieved.

-

- Grid Support: During periods of high demand, EMS can dispatch stored energy from the BESS to help balance the grid, preventing overloads and ensuring stable power supply.

Real-World Impact

The effectiveness of AI-powered EMS in BESS containers is best illustrated through real-world examples:

Case Study: New York Commercial Building (2024

| Protection Level | Technology Employed | Mechanism of Action |

|---|---|---|

| Cell Level | Flame-retardant electrolytes and ceramic coatings | These materials create a barrier around individual cells, preventing fire spread even if a cell sustains damage due to factors like mechanical vibration or internal short circuits. |

| Module Level | Aerosol fire-extinguishing systems | Equipped with sensitive heat and smoke detectors, these systems release non-toxic aerosol particles that suppress fires within 10 seconds, isolating the affected area. |

| Container Level | Perfluorohexanone fire-extinguishing systems | This non-conductive, environmentally friendly agent rapidly cools the entire container to below 50°C within one minute, effectively eliminating the risk of re-ignition. |

These findings align with data from the U.S. Department of Energy (DOE), which confirms that BESS containers optimized by EMS deliver 20–30% higher economic value than those managed through manual systems. For further insights, refer to the DOE’s article on Energy Management Systems Boosting BESS Value.

Conclusion: The Future of BESS Containers—And Maxbo Solar’s Role

Innovative technologies have transformed BESS containers from “backup power” to “grid assets.” To recap:

- Battery materials (high-nickel, LFP) balance energy density and safety.

- Thermal management (liquid cooling + AI algorithms) extends battery life.

- Safety systems (multi-level fire/electrical protection) eliminate risks.

- EMS turns energy storage into cost savings.

What’s next? By 2030, we’ll see:

- Solid-state batteries in mainstream BESS (costs <$100/kWh).

- AI EMS that predicts grid demand 24 hours in advance.

- Zero-waste BESS (100% recyclable batteries).

Maxbo Solar: Your Partner in Cutting-Edge BESS Containers

At Maxbo Solar (www.maxbo-solar.com), we don’t just sell BESS containers—we build custom solutions that integrate all the technologies above. Here’s what sets us apart:

- Tailored Design: We match batteries (high-nickel or LFP) and EMS to your needs (e.g., utility-scale vs. commercial).

- Proven Performance: Our BESS containers have a 99.8% uptime rate (based on 2024 client data) and meet UL, IEC, and TÜV safety standards.

- End-to-End Support: From installation to maintenance, our team ensures your BESS runs smoothly for 20+ years.

Whether you’re a utility company needing 100+ MWh of storage or a business wanting to cut electricity bills, we’ve got you covered. Visit www.maxbo-solar.com to learn more—let’s build a more stable, efficient energy future together.