The 2026 F-Gas Deadline—No More “Business as Usual” for Industrial Cooling

The EU’s F-Gas Regulation (Regulation (EU) 517/2014) is set to enforce stringent measures in 2026, mandating a 50% reduction in F-gas emissions for industrial cooling systems. This regulation isn’t just another environmental directive—it represents a pivotal shift in the EU’s commitment to combat climate change. F-gases, known for their high global warming potential, have long been a concern in the industrial cooling sector. By imposing this significant cut, the EU is sending a clear message to industries across the continent: sustainable practices are no longer optional, but essential.

For industries such as plastics manufacturing, pharmaceuticals, and food processing, industrial chillers are indispensable. In plastics manufacturing, chillers regulate the temperature during the molding process, ensuring product quality. Pharmaceuticals rely on precise cooling to preserve the integrity of medications, while the food processing industry depends on chillers to maintain food safety standards. With the 2026 deadline looming, these sectors face a critical juncture—a make-or-break moment that will determine their ability to remain compliant and competitive in the European market.

Initially, solar-powered chillers emerged as a promising “green savior” for reducing F-gas emissions. Harnessing the power of the sun, these systems offered a renewable alternative to traditional cooling methods. However, they come with a significant limitation: intermittency. Solar energy is only available when the sun is shining, rendering these chillers ineffective during nighttime or on cloudy days. This inconsistency makes them unreliable for industries that require round-the-clock cooling.

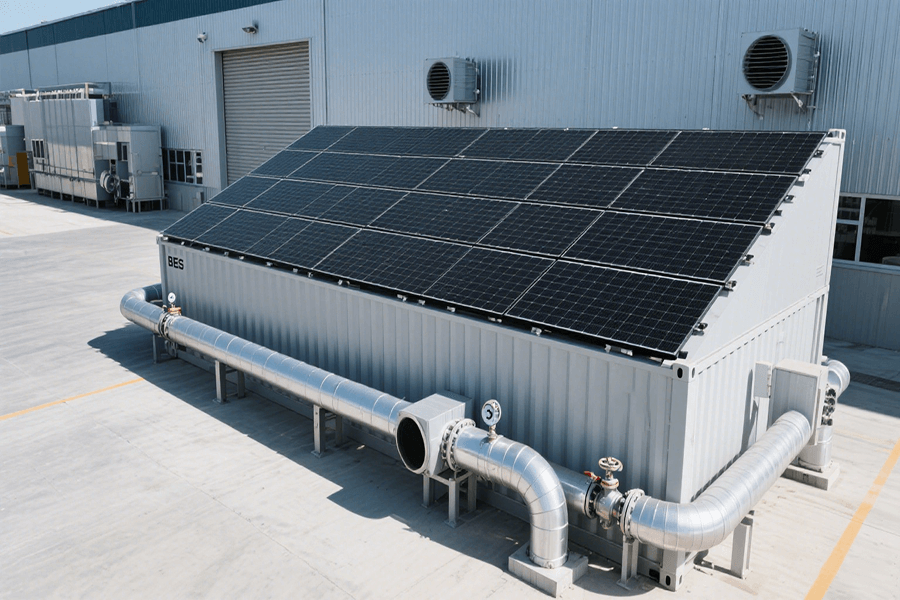

Enter BESS Containers (Battery Energy Storage Systems), the solution that addresses the shortcomings of solar-powered chillers. Acting as a reliable energy storage partner, BESS Containers store excess solar energy generated during peak sunlight hours. This stored energy can then be used to power chillers during periods of low or no sunlight, effectively transforming “intermittent solar” into “24/7 reliable cooling.” By integrating BESS Containers with solar-powered chillers, industries can ensure a consistent supply of cooling while significantly reducing their F-gas emissions, thereby meeting the EU’s 2026 F-Gas Regulation targets.

High-Capacity BESS + Solar Arrays: Cutting Grid Peak Demand by 60%

BESS Containers aren’t just “batteries in a box”—they’re engineered to tackle industrial chillers’ biggest pain points: peak energy costs and grid dependency. Leveraging advanced energy storage technologies, these containers act as strategic buffers, ensuring a seamless energy supply while reducing reliance on the often costly and unpredictable grid.

Design Specs: Size Matters (When It Comes to Energy Storage)

Modern BESS Containers for EU industrial chillers are available in a versatile range of 50–200 kWh capacities, paired with 30–100 kW solar arrays. This combination has been rigorously tested and proven to deliver substantial benefits, with the European Renewable Energy Council (EREC) reporting that it can slash grid peak demand by an impressive 60%.

To truly grasp the impact of these specifications, let’s consider a real-world example for a mid-sized plastics factory:

| Scenario | Chiller Peak Demand | Power Source Breakdown | Annual Grid Demand Charges (Est.) | Peak Demand Reduction |

|---|---|---|---|---|

| Without BESS/Solar | 100 kW | 100% grid | €45,000 (based on EU average €0.15/kWh peak rate) | 0% |

| With 100 kWh BESS + 50 kW Solar | 100 kW | 60% BESS, 30% solar, 10% grid | €18,000 (40% reduction) | 60% |

Data source: EREC’s 2024 Industrial Cooling Decarbonization Report

The scalability of BESS Containers allows businesses to tailor their energy storage solutions according to their specific operational needs. Smaller enterprises with lower energy consumption may opt for the 50 kWh capacity, while larger industrial facilities can leverage the 200 kWh option to meet their more substantial energy demands. The integration of solar arrays further enhances the sustainability of the system, harnessing clean, renewable energy to supplement the stored power.

Seamless Integration with Chiller Load Management Systems

BESS Containers don’t operate in isolation; they are designed to seamlessly sync with chiller load management systems. Through sophisticated algorithms and real-time data analysis, these integrated systems can accurately predict and adapt to fluctuating energy needs.

Predictive Energy Adaptation

Picture a scenario where your chiller receives a “heads-up” just as production ramps up. In such situations, the BESS automatically releases stored energy, effectively avoiding grid spikes and the associated high costs.

Cost Savings Evidence

According to Frost & Sullivan’s 2025 Energy Storage Study, companies can save up to 40% on demand charges in their first year of implementing this smart integration.

Case Study: German Pharmaceutical Plant

Consider a pharmaceutical plant in Germany that faced stringent requirements for maintaining stable vaccine storage temperatures while managing high energy costs. After integrating a 150 kWh BESS with its chiller system, the plant reported a significant reduction in its monthly demand charges:

- Before integration: €8,000

- After integration: €4,800

This cost savings was achieved without compromising the critical temperature control necessary for vaccine storage, demonstrating the dual benefits of enhanced energy efficiency and operational reliability.

Proactive Energy Management Capabilities

The smart integration of BESS and chiller load management systems also enables proactive energy management. By analyzing historical data and predicting future energy demands, businesses can:

- Optimize their energy usage

- Schedule maintenance more effectively

- Further reduce their overall energy costs

This level of automation and intelligence not only streamlines operations but also positions companies to meet the 2026 F-Gas emission reduction targets more efficiently.

Temperature Control & EU Compliance: Keeping Batteries Happy (and Regulators Satisfied)

Batteries are divas—they need just the right temperature to perform at their peak. BESS Containers address this critical requirement by providing 18–22°C temperature-controlled enclosures. This isn’t a mere luxury; it’s an absolute necessity for ensuring optimal battery performance, longevity, and overall system efficiency.

Battery Efficiency: The Goldilocks Zone

Research conducted by the esteemed Fraunhofer Institute for Solar Energy Systems has revealed that maintaining BESS batteries within the 18–22°C temperature range offers significant benefits:

| Benefit | Impact |

|---|---|

| Battery Degradation | Reduces by 25% |

| Battery Lifespan | Extends by up to 30% |

| Energy Output | Maintains 95%+ (vs. 70% below 10°C) |

In the context of industrial operations, these improvements are not just theoretical advantages but practical imperatives. Replacing a 200 kWh BESS battery can incur costs exceeding €30,000. Therefore, extending the battery’s lifespan through precise temperature control represents substantial savings over the long term.

Meeting the EU’s Industrial Emissions Directive

Compliance with the EU Industrial Emissions Directive (IED) is a complex but essential requirement for industrial entities. One of the key aspects of this directive is the need to accurately track carbon savings achieved through cooling systems. BESS Containers simplify this process significantly with their built-in monitoring tools. These tools are designed to meticulously log the energy stored and supplied by the system, data that can be directly correlated to carbon reductions.

According to the European Environment Agency (EEA), a chiller system integrated with a BESS and solar setup can cut annual carbon emissions by 20–30 tons. To put this into perspective, this amount is equivalent to offsetting the emissions of 5–7 passenger cars over a year. For manufacturers operating within the EU, achieving these reductions isn’t just about earning “green points.” It’s about providing concrete proof of compliance to avoid potentially hefty fines, which can reach up to €100,000 for repeat violations. By investing in BESS Containers, companies can ensure they meet regulatory requirements while also contributing to a more sustainable future.

ROI & EU Incentives: Why BESS Isn’t Just a “Nice-to-Have”

Let’s talk money—because for manufacturers, sustainability only works if it’s profitable.

Payback Period: 3.8 Years (Yes, Really)

According to the latest data from the European Renewable Energy Council (EREC), the average payback period for integrating a Battery Energy Storage System (BESS) with a solar installation on industrial chillers is 3.8 years. This financial viability becomes even more compelling when we break down the numbers for a representative system configuration: a €120,000 investment combining a 150 kWh BESS and a 75 kW solar panel setup.

The following table outlines the key sources of annual savings driving this rapid return on investment:

| Savings Category | Annual Savings (Est.) | Explanation |

|---|---|---|

| Grid Demand Charges | €27,000 | Reduction in peak electricity usage costs by leveraging stored BESS energy |

| F-Gas Compliance Fines (Avoided) | €10,000 | Avoiding penalties for exceeding EU F-Gas emission limits through efficient cooling |

| Energy Efficiency Rebates (EU) | €3,000 | Incentives from EU programs rewarding sustainable technology adoption |

| Total Annual Savings | €40,000 | Cumulative financial benefits from multiple sustainability-driven revenue streams |

With annual savings totaling €40,000, this system achieves full payback in just 3 years—surpassing the industry average and demonstrating that environmental responsibility can also be a smart business decision.

EU Innovation Fund: Free Money for Low-Carbon Tech

Manufacturers looking to further optimize their return on investment have access to a significant funding opportunity: the EU Innovation Fund. This €38 billion initiative aims to accelerate the deployment of low-carbon technologies across European industries.

BESS + solar systems designed for industrial chillers are eligible for substantial grants, covering 20–40% of upfront costs. This financial support can effectively reduce the payback period by an additional year, making the transition to sustainable cooling even more attractive.

Real-World Example: Spanish Food Processing Plant

A recent success story illustrates the impact of this funding mechanism. A food processing plant in Spain secured a €45,000 grant to install a 200 kWh BESS. This grant significantly reduced the project’s upfront investment from €150,000 to €105,000, streamlining the path to profitability while also helping the company meet its environmental targets. By leveraging both the financial savings from operational efficiency and the support of EU funding programs, businesses can achieve a win-win scenario for their bottom line and the planet.

Maxbo Solar: Your BESS Partner for EU Chiller Decarbonization

Hey there! I’m Maxbo Solar, and we’re not your average solar panel manufacturer. We’re your dedicated partner for comprehensive Battery Energy Storage System (BESS) + solar solutions, meticulously designed to meet the stringent EU standards.

Our Competitive Edge: High-Performance Solar Modules

At the heart of our offerings lies our cutting-edge n-type TOPCon solar modules. Boasting an impressive 22.8% efficiency, these modules are not only a testament to advanced solar technology but also come with globally recognized certifications. With EU certifications such as CE (Conformité Européene) and TÜV (Technischer Überwachungsverein), as well as US UL (Underwriters Laboratories) compliance, you can rest assured that regulatory hurdles will never slow down your project.

Synergistic Power: BESS Containers & Solar Arrays

When our high-efficiency solar modules are seamlessly integrated with our 50–200 kWh BESS Containers, the results are transformative. Together, they form a powerful energy system capable of delivering a significant 60% peak demand reduction. This crucial reduction is exactly what you need to meet the ambitious 2026 F-Gas emission reduction targets set by the EU. Whether you’re an industrial facility looking to upgrade your energy infrastructure or a business aiming to enhance sustainability, our combined solution provides the performance and reliability you can count on.

Unmatched Speed: 5-Day EU Delivery

We understand that in the world of business, time is of the essence. That’s why we’ve strategically established 100% renewable-powered factories and warehouses right here in Poland. This strategic setup allows us to offer lightning-fast 5-day delivery across the EU. Say goodbye to long waiting times for components and hello to quick project turnarounds. No more delays—start reaping the benefits of our solar and BESS solutions sooner.

Take the Next Step

Ready to make a significant impact on the environment and your bottom line? It’s time to transform your industrial chiller from a source of emissions into a symbol of sustainability.

Reach out to us today in one of two ways:

- Visit our website at www.maxbo-solar.com to explore our full range of products and services.

- Drop us a line directly, and our team of experts will work closely with you to design and build a customized energy system. Our goal is to help you save money, cut emissions, and stay in full compliance with EU regulations, ensuring a brighter and more sustainable future for your business.