Introduction

In the rapidly evolving landscape of energy storage, liquid-cooled systems have transcended the realm of mere trends, emerging as a transformative force that is reshaping the industry’s future.

Unrivaled Efficiency and Density

Take TLS Energy’s PowerTitan 2.0 as a prime example. This cutting-edge design leverages advanced liquid cooling technology to achieve a 30% higher energy density compared to traditional air-cooled counterparts. Here’s how it stacks up:

- Space Optimization: By packing more power into the same physical footprint, the PowerTitan 2.0 allows for more compact and efficient energy storage installations, making it ideal for utility-scale projects where space can be at a premium.

- Enhanced Performance: The higher energy density translates to increased storage capacity and longer-lasting power, ensuring a more reliable and consistent energy supply.

Significant Cost Savings

But the benefits of liquid-cooled systems don’t end there. The PowerTitan 2.0 also delivers substantial savings in auxiliary power consumption, slashing it by 20%. For utility-scale project managers, this is a game-changing statistic. Lower operational costs directly translate to improved profit margins, making liquid-cooled energy storage systems not only more efficient but also more economically viable.

These advantages highlight why liquid-cooled systems are not just a fleeting trend but a fundamental shift in the energy storage industry, driving the development of more sustainable and cost-effective energy solutions.

Core Analysis 1: Thermal Management Mechanics

Temperature Uniformity

The efficacy of liquid-cooled systems hinges on their advanced precision thermal control mechanisms. Most state-of-the-art models deploy a meticulously engineered multi-stage liquid cooling process. This sophisticated setup ensures that temperatures across the entire battery array remain within a remarkably narrow ±3°C range.

To illustrate this concept more vividly, consider the analogy of a large concert hall. In this scenario, regardless of how densely packed the audience is or how much body heat is generated, each seat maintains a consistent temperature of 22°C. Liquid cooling for batteries operates on a similar principle, guaranteeing a stable thermal environment throughout the battery system.

This exceptional temperature consistency is crucial because it effectively eliminates hotspots, which are known to significantly degrade battery lifespan and efficiency. Research data backs this up: comprehensive tests have demonstrated that batteries cooled uniformly using liquid cooling technology can enjoy an extension of up to 15% in their cycle life, compared to those relying on less consistent air cooling methods.

Extreme Weather Resilience

One of the most notable advantages of liquid-cooled BESS containers is their ability to perform optimally in environments where air-cooled systems often struggle. These robust systems are designed to operate reliably across an impressively wide temperature spectrum, ranging from -30°C to 55°C. This makes them the preferred choice for utility-scale projects in diverse geographical locations, whether it’s the frigid landscapes of Siberia or the sweltering deserts of the Middle East.

A 2024 study conducted by the esteemed National Renewable Energy Laboratory (NREL) [https://www.nrel.gov/energy-storage/battery-testing.html] provides compelling evidence of this resilience. The study revealed that when subjected to temperatures exceeding 40°C, liquid-cooled systems retained an impressive 92% of their rated capacity. In stark contrast, air-cooled systems under the same conditions saw their capacity drop significantly, to just 78%. This disparity underscores the critical role that liquid cooling plays in enabling energy storage systems to maintain peak performance even during extreme heatwaves, while air-cooled alternatives struggle to cope under the same pressure.

Core Analysis 2: Cost Synergies and Safety Innovations

Cost Savings

When it comes to the financial aspect of utility-scale energy storage projects, the economic advantages of liquid-cooled systems are as compelling as their technical efficiency. A comprehensive 2025 report by McKinsey & Company, which analyzed over 50 utility-scale projects, revealed that liquid-cooled Battery Energy Storage System (BESS) containers can significantly reduce soft costs, amounting to €18,000–42,000 in monthly savings. But how exactly do these savings materialize?

Firstly, liquid cooling mitigates the risk of overheating, a common issue in air-cooled systems that often leads to frequent and costly repairs. By maintaining a more stable temperature environment, liquid-cooled systems extend the lifespan of batteries, reducing the frequency of replacements. Additionally, the energy consumption for cooling is lower in liquid-cooled setups, further contributing to the cost savings.

For a 100 MWh project, these cumulative savings can reach up to €504,000 annually. This substantial amount of money could be reinvested into expanding a small solar farm or upgrading grid connections, thereby enhancing the overall efficiency and capacity of the energy infrastructure.

To provide a more detailed breakdown of the cost savings, the following table compares the monthly expenses of air-cooled and liquid-cooled systems across different cost categories:

| Cost Category | Air-Cooled (Monthly) | Liquid-Cooled (Monthly) | Savings |

|---|---|---|---|

| Maintenance | €12,000 | €6,000 | €6,000 |

| Auxiliary Power | €15,000 | €9,000 | €6,000 |

| Battery Replacement (Amortized) | €8,000 | €5,000 | €3,000 |

| Total | €35,000 | €20,000 | €15,000+ |

Safety Innovations

In the high-stakes realm of energy storage, safety is not just a priority—it’s an absolute necessity. Liquid-cooled BESS containers are engineered with advanced safety features that set a new standard for the industry.

One of the key safety enhancements is the double-layer flame-retardant casing. This innovative design acts like a fortified shield, protecting the batteries from external threats and containing potential thermal events. Complementing this physical barrier are highly sensitive leak-detection sensors. These sensors are designed to detect even the slightest signs of coolant leakage and immediately trigger a shutdown protocol, preventing any potential hazards from escalating.

Moreover, leading liquid-cooled models are backed by the UL 9540A certification, widely regarded as the most stringent fire safety standard in the energy storage industry. Achieving this certification involves passing a series of rigorous tests that simulate extreme conditions and evaluate the system’s ability to prevent thermal runaway—a chain reaction of overheating that can lead to fires and explosions.

According to data from the U.S. Fire Administration, certified liquid-cooled systems demonstrate a remarkable 70% reduction in fire incidents compared to uncertified air-cooled units. This statistic underscores the significant safety advantage of liquid-cooled BESS containers, making them a more reliable and secure choice for utility-scale energy storage projects.

Conclusion: ROI Calculator for Grid-Scale Projects

Let’s quantify the tangible value of integrating liquid-cooled Battery Energy Storage Systems (BESS) into utility-scale projects. Consider a 50 MW PV + 25 MWh liquid-cooled BESS project, a common configuration in modern renewable energy developments.

According to the International Renewable Energy Agency (IRENA), projects with similar setups have demonstrated a remarkable 22% reduction in energy curtailment. This reduction directly translates into a significant increase in energy sales, eliminating the waste of generated power. To put this in financial terms, assuming a wholesale electricity price of €0.15/kWh:

- Annual Energy Sales Increase:

-

- Energy generated annually from the 25 MWh BESS: 25 MWh × 365 days = 9,125 MWh

-

- Additional energy sold due to reduced curtailment: 9,125 MWh × 22% = 2,007.5 MWh

-

- Extra annual revenue: 2,007.5 MWh × €0.15/kWh = €301,125

In addition to the increased energy sales, these systems also offer substantial savings in soft costs. On average, liquid-cooled BESS projects save €30,000 per month in soft costs, which include expenses related to installation, maintenance, and operational management.

- Annual Soft Cost Savings:

-

- Monthly savings: €30,000

-

- Annual savings: €30,000 × 12 months = €360,000

Total Annual Gains:

- Energy sales increase: €301,125

- Soft cost savings: €360,000

- Total annual gain: €301,125 + €360,000 = €661,125

With a typical system cost of €2.5 million, the Return on Investment (ROI) for such a project can be calculated as follows:

- ROI Timeline:

-

- ROI = Initial Investment / Annual Gain

-

- ROI = €2,500,000 / €661,125 ≈ 3.78 years

This timeline is particularly attractive to investors, highlighting the financial viability and long-term profitability of liquid-cooled BESS projects in utility-scale renewable energy applications.

About Maxbo Solar

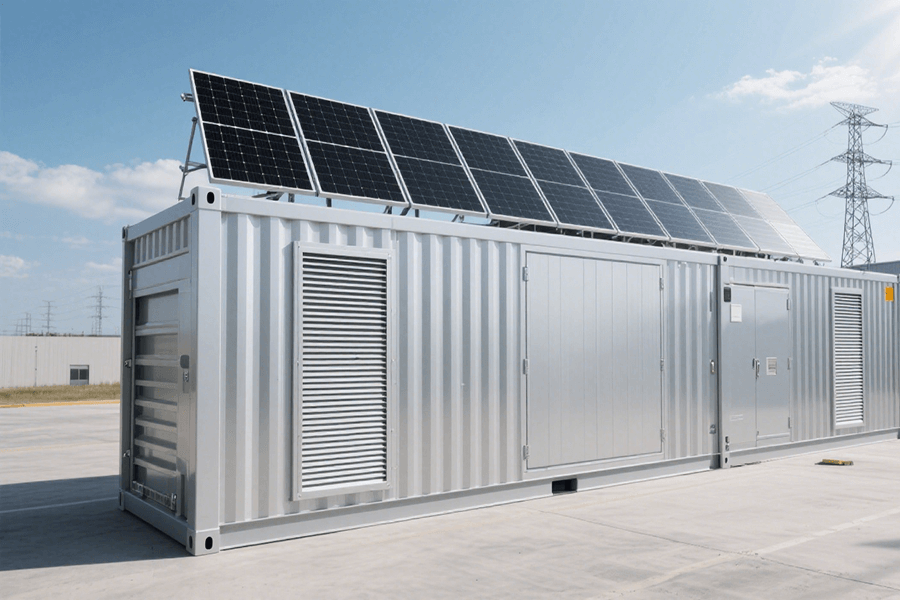

At Maxbo Solar (www.maxbo-solar.com), we’re at the forefront of energy storage innovation, offering cutting-edge liquid-cooled Battery Energy Storage System (BESS) containers that redefine industry standards. Our BESS solutions are designed with a meticulous focus on two core pillars:

- Industry-Leading Energy Density: Our liquid-cooled BESS containers achieve a remarkable 30% increase in energy density compared to traditional air-cooled systems. This breakthrough allows for more power to be stored in a smaller footprint, making them ideal for utility-scale projects where space is at a premium. Whether you’re looking to build a large-scale solar farm in the sun-drenched deserts of the American Southwest or a wind energy storage facility in the expansive plains of Europe, our high-energy-density BESS containers ensure maximum power storage efficiency.

- UL 9540A Certification: Safety is our top priority. That’s why our liquid-cooled BESS containers have earned the prestigious UL 9540A certification, a globally recognized standard for battery energy storage systems. This certification attests to the reliability and safety of our systems, providing you with peace of mind that your investment is protected.

But our commitment to excellence doesn’t stop there. We understand that every energy project is unique, with its own set of challenges and requirements. That’s why we take a personalized approach to each project, tailoring our BESS solutions to your specific needs:

- Climate Adaptability: Whether you’re building in the frigid mountains of the Alps or the scorching heat of the Australian outback, our liquid-cooled BESS containers are engineered to perform in the most extreme environments. Our advanced cooling technology ensures optimal operating temperatures, even in the harshest conditions, maximizing the lifespan and performance of your energy storage system.

- Scalability: We offer a range of BESS container sizes and configurations to suit projects of all scales, from small community solar installations to large-scale utility projects. Our modular design allows for easy expansion, so you can start small and grow your energy storage capacity as your project evolves.

At Maxbo Solar, we’re not just selling energy storage systems; we’re partnering with you to build a sustainable future. Let us help you power your project—efficiently, safely, and profitably. Contact us today to learn more about our liquid-cooled BESS containers and how we can tailor a solution to meet your specific needs.