Traditional Energy Storage Methods Defined

Lead – acid Batteries: The Pioneers of Energy Storage

Lead – acid batteries are like the granddaddies of the battery world, having been invented way back in 1859. They’re so old – school that they make your grandparents seem like they’re from the digital age! These batteries work through a chemical reaction between lead, lead dioxide, and sulfuric acid. It’s like a little chemical dance party inside the battery.

- Discharge Process: When the battery discharges, lead and lead dioxide react with sulfuric acid to produce lead sulfate and water, releasing electrical energy in the process.

- Charge Process: And when it’s time to charge up, the reaction reverses.

There are different types of lead – acid batteries:

- Starting Batteries: The ones in your car, the starting batteries, are like the energetic morning people. They need to give a big, powerful “kick” to get your car engine roaring to life.

- Deep – Cycle Batteries: On the other hand, deep – cycle batteries, which you might find in golf carts, are more like the steady, long – distance runners. They can provide a consistent power output over a longer period.

However, their energy density is relatively low, typically around 30 – 50 Wh/kg (source: Battery University). This means they need a larger volume and weight to store the same amount of energy compared to some newer technologies.

Pumped – hydro storage: The giant water – slide of the energy world

Pumped – hydro storage operates much like an energy – focused giant water – slide. Here’s its step – by – step process:

Off – peak energy storage phase:

During off – peak hours, when electricity prices are lower and demand is subdued, power is harnessed to pump water from a lower reservoir to a higher one. This is analogous to the arduous task of carrying water uphill, storing potential energy in the elevated water.

Peak demand generation phase:

When electricity demand surges, the water is released from the higher reservoir. As it flows down through turbines, it drives them to spin, converting the stored potential energy into electrical energy. It’s the hydrological equivalent of a thrilling water – slide descent, but instead of eliciting screams of joy, it generates valuable electrical power.

Key characteristics and challenges

- Scale and geographical requirements:

This energy storage method is inherently large – scale. Its effectiveness hinges on specific geographical features, such as mountains and valleys. These topographical elements are crucial for creating the necessary elevation difference between the two reservoirs.

- Infrastructure complexity:

Building a pumped – hydro storage facility is a monumental undertaking. It entails constructing two reservoirs at distinct elevations, installing high – capacity pumps and turbines, and laying pipelines for efficient water transport.

- Efficiency:

According to the International Hydropower Association, the efficiency of pumped – hydro storage systems typically falls within the range of 70 – 85%. However, several factors can impact this efficiency:

-

- Water evaporation: Evaporation from the reservoirs over time reduces the available water volume for energy generation.

-

- Turbine inefficiencies: Mechanical losses and imperfections in the turbines can also lead to a decrease in overall system efficiency.

Flywheel Energy Storage: A Dynamic Power Solution

Flywheel energy storage is a fascinating concept. Picture a spinning top that defies inertia, continuously twirling as it accumulates energy. This is the fundamental principle behind flywheels, which store energy through rotational motion.

How It Works

- Energy Storage Phase: An electric motor accelerates the flywheel to high speeds. The faster the rotation, the greater the stored energy.

- Energy Release Phase: When power is needed, a generator converts the flywheel’s rotational energy back into electricity.

Real – World Applications

Flywheels excel in short – term power backup for industrial processes. For instance, in manufacturing plants, they provide an immediate power boost during brief outages, safeguarding sensitive equipment.

Technical Characteristics

- Power Density: Flywheels offer high power density, enabling rapid delivery of substantial power.

- Energy Density: However, their energy density lags behind battery – based systems, typically ranging from 1 – 10 Wh/kg (source: Department of Energy).

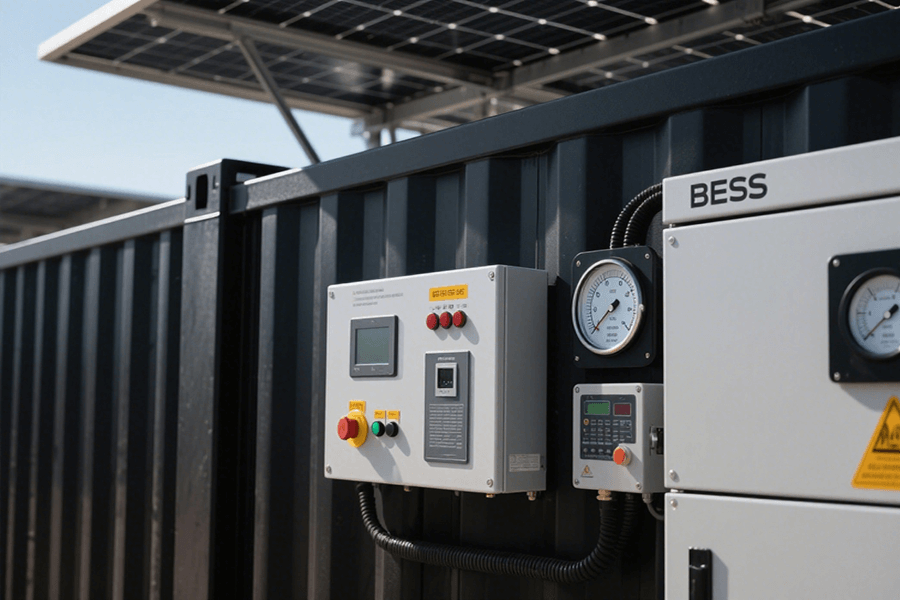

Comparing BESS Containers with Traditional Methods

Energy Density

BESS containers are like the tiny superheroes of energy storage when it comes to energy density. They pack a whole lot more energy punch per unit volume compared to lead – acid batteries. For instance, some advanced BESS containers can achieve an energy density of up to 200 – 300 Wh/kg (source: BloombergNEF), which is significantly higher than the 30 – 50 Wh/kg of lead – acid batteries. It’s like comparing a compact, high – powered sports car to a big, old – fashioned truck.

Pumped – hydro storage, due to its reliance on large volumes of water and the physical infrastructure, has a very low energy density in terms of the space it occupies. The energy is stored in the potential energy of the water, and considering the large reservoirs and the associated infrastructure, the energy density is negligible in comparison to BESS containers. Flywheel energy storage, as mentioned earlier, typically has an energy density in the range of 1 – 10 Wh/kg, which is also much lower than what BESS containers can offer.

Efficiency

BESS containers are like the efficient little energy – saving ninjas of the energy storage world. They can charge and discharge with relatively high round – trip efficiency. Many modern BESS containers achieve an efficiency of around 85 – 95% (source: National Renewable Energy Laboratory (NREL)). This means that when they store energy, they lose very little in the process of charging and discharging.

Lead – acid batteries, on the other hand, have a lower efficiency, usually around 70 – 80% (source: Battery University). This is because of various factors such as heat generation during charging and discharging, which leads to energy losses. Pumped – hydro storage, while having a decent efficiency of 70 – 85% as mentioned before, can be affected by factors like water evaporation from the reservoirs, friction in the turbines, and inefficiencies in the pumps. Flywheel energy storage also has an efficiency that typically ranges from 80 – 90% (source: Department of Energy), but it can be impacted by factors such as air resistance and bearing friction.

Cost

Let’s break down the costs of BESS containers. The initial investment in a BESS container includes the cost of the battery modules, power conversion systems (PCS), balance of plant (BOP), installation, labor, and engineering, procurement, and construction (EPC) costs. According to a study by BloombergNEF, battery modules in BESS containers can cost around (150 – )200 per kWh. The power conversion systems usually cost about (50 – )80 per kWh. The balance of plant costs for BESS containers, which include things like site preparation, foundations, and structures, are significantly lower compared to traditional methods. The NREL found that BOP costs can be 60 – 70% lower for containerized systems due to reduced civil works and faster installation times. Installation and labor costs are also 50 – 70% lower for BESS containers, and EPC costs can be 30 – 50% lower (source: Lazard).

When it comes to traditional methods, lead – acid batteries are relatively cheap upfront, with the battery cost being around (50 – )100 per kWh. However, they have high replacement costs as their lifespan is relatively short. Pumped – hydro storage is extremely expensive to build, with costs ranging from (500 – )5000 per kWh depending on the location and scale. But in the long run, if the geographical conditions are right, the operation costs can be low. Flywheel energy storage has an upfront cost of around (300 – )1000 per kWh, and its maintenance costs can be relatively high due to the high – speed rotating components.

|

Cost Component

|

BESS Containers

|

Lead – Acid Batteries

|

Pumped – Hydro Storage

|

Flywheel Energy Storage

|

|

Battery Modules

|

(150 – )200/kWh

|

(50 – )100/kWh

|

N/A

|

N/A

|

|

Power Conversion (PCS)

|

(50 – )80/kWh

|

N/A

|

N/A

|

N/A

|

|

Balance of Plant (BOP)

|

60 – 70% lower than traditional

|

N/A

|

High (depends on location)

|

N/A

|

|

Installation & Labour

|

50 – 70% lower than traditional

|

N/A

|

High (depends on location)

|

N/A

|

|

Engineering, Procurement, Construction (EPC)

|

30 – 50% lower than traditional

|

N/A

|

High (depends on location)

|

N/A

|

|

Upfront Cost Range

|

(290 – )460/kWh

|

(50 – )100/kWh (but high replacement cost)

|

(500 – )5000/kWh

|

(300 – )1000/kWh

|

Lifespan

BESS containers, especially those with advanced battery chemistries like lithium – ion, can have a long lifespan if properly maintained. They’re like the energizer bunnies of energy storage, just keeping on going. Many BESS containers are designed to last for 10 – 20 years (source: Maxbo Solar).

Lead – acid batteries, unfortunately, have a relatively short lifespan. They typically last for 3 – 5 years in automotive applications and 5 – 10 years in deep – cycle applications (source: Battery University). This shorter lifespan means more frequent replacements, which adds to the overall cost. Pumped – hydro storage systems, if well – maintained, can have a very long lifespan, often several decades. Flywheel energy storage systems also have a lifespan that can range from 10 – 20 years, but it can be affected by factors such as the wear and tear of the rotating components.

Advantages of BESS Containers

Modular Design and Scalability

BESS containers are like the Lego blocks of energy storage. Their modular design allows for easy scalability. You can add or remove containers just like you would add or remove Lego bricks to build a tower. This makes it incredibly simple to scale up or down an energy storage system. For example, if a small – scale solar power project initially starts with one BESS container but later needs more energy storage capacity as the project expands, additional containers can be easily added. It’s a hassle – free way to adapt to changing energy needs.

Faster Response Times

BESS containers are like sprinters jumping off the starting block when it comes to responding to changes in energy demand. They can quickly charge or discharge electricity in response to fluctuations in the power grid. In contrast, some traditional methods, like pumped – hydro storage, take longer to start up and adjust their power output. The fast response time of BESS containers is crucial in maintaining grid stability, especially during sudden spikes or drops in electricity demand.

Better Adaptability to Different Environments

BESS containers are the chameleons of energy storage. They can be used in a wide variety of settings, from the hot and arid deserts to the cold and snowy mountain tops. Their compact and self – contained design allows them to be easily installed in different environments. For instance, in remote areas where space is limited, BESS containers can provide an efficient energy storage solution without the need for extensive infrastructure modifications.

Large – Scale Applications with Cost – per – Unit – Energy – Stored as a Major Factor

Large – Scale Applications with Cost – per – Unit – Energy – Stored as a Major Factor

When it comes to large – scale energy storage deployments, where the cost – per – unit – energy – stored is a critical determinant, certain traditional methods hold a significant edge. Take pumped – hydro storage, for example. Its relatively low upfront capital expenditure makes it an appealing choice, despite potential limitations in other areas.

In regions blessed with suitable geographical features—such as mountainous terrains with deep valleys—constructing a pumped – hydro storage facility can be an astute, cost – effective solution for large – scale energy storage needs. Moreover, the long – term operational costs of pumped – hydro systems tend to be relatively modest, further enhancing their viability when cost efficiency is paramount.

Specific Geographical or Industrial Requirements

Geographical Constraints:

- Pumped – Hydro Storage: In areas with abundant water resources and the right topographical conditions, pumped – hydro storage is often the natural choice. Mountainous regions with large rivers and suitable elevation differences are ideal for building pumped – hydro plants. These facilities can efficiently store and generate electricity, leveraging the region’s natural assets.

Industrial Demands:

- Flywheel Energy Storage: In certain industrial settings, the unique characteristics of flywheel energy storage offer distinct advantages. Manufacturing plants, for instance, frequently encounter short – term power interruptions. In such scenarios, where there’s a need for a quick burst of power rather than long – term energy storage, flywheel systems shine. Their ability to rapidly discharge stored energy makes them a highly suitable option for maintaining continuous operations during brief outages.

Maxbo Solar’s Take (First – Person)

At Maxbo Solar, we’ve been knee – deep in the energy storage game for quite some time. Our website, www.maxbo-solar.com, is like a treasure trove of information for all things related to solar and energy storage. We’ve had the opportunity to work on numerous projects involving BESS containers and traditional energy storage methods.

Case Study 1: Rural Solar – Powered Microgrid

In one of our solar – powered microgrid projects in a rural area, we opted for BESS containers. The client needed an energy storage solution that could quickly respond to the intermittent power generation from the solar panels.

The BESS containers’ fast response times and modular design were perfect for the project. However, during the installation, we encountered challenges:

- Ventilation Issue: Ensuring proper ventilation in the containers during hot summer months was crucial.

- Solution: We overcame this by installing additional cooling systems.

The project was a huge success, enabling the client to achieve a stable power supply even during cloudy days.

Case Study 2: Large – Scale Solar Power Plant

In another large – scale solar power plant project, we considered both BESS containers and pumped – hydro storage. Given the plant’s geographical location—near a large river with suitable terrain—we decided on a hybrid solution:

- Components: A combination of solar power, pumped – hydro storage, and a small number of BESS containers for quick response during sudden power fluctuations.

- Benefits Breakdown:

-

- Pumped – Hydro Storage: Provided the bulk of the energy storage capacity at a relatively low long – term cost.

-

- BESS Containers: Added an extra layer of flexibility and fast response.

Future Outlook

Looking to the future, we see BESS containers playing an increasingly important role in energy storage, especially in areas where:

- Space is limited

- Quick response times are crucial

However, we also believe that traditional energy storage methods like pumped – hydro and flywheel energy storage will continue to have their place in the market, especially in large – scale applications with specific geographical or industrial requirements. We’re constantly researching and developing new ways to integrate different energy storage technologies to provide the best solutions for our clients.

Conclusion

In summary, when juxtaposing Battery Energy Storage System (BESS) containers against traditional energy storage methodologies, a nuanced landscape of advantages and limitations emerges. BESS containers distinguish themselves through several key attributes:

- Exceptional Energy Density: Their compact design enables a significantly higher energy – to – volume ratio, making them ideal for space – constrained urban installations and remote off – grid locations where real estate is at a premium.

- Lightning – Fast Response Times: With the ability to rapidly charge and discharge, BESS containers can instantaneously balance grid fluctuations, providing crucial support during peak demand or sudden power outages.

- Modular Architecture: Composed of scalable battery modules, these systems can be easily customized to meet specific energy demands. Whether it’s a small – scale residential setup or a large – capacity commercial project, BESS containers offer unparalleled flexibility in design and expansion.

- Environmental Adaptability: Engineered to operate efficiently across a wide range of temperatures and weather conditions, BESS containers are suitable for diverse geographical locations, from the arid deserts to the frigid polar regions.

Conversely, traditional methods such as pumped – hydro storage hold their ground in terms of cost – effectiveness, especially for large – scale, long – duration energy storage requirements. Their established infrastructure and lower long – term operational costs make them a viable option in regions with suitable topographical features.