” Battery energy storage lithium batteries are usually assembled in the battery compartment for use, in the charge and discharge process will continue to heat, heat is difficult to conduct to the external environment in time, but the best working temperature of energy storage lithium batteries is 25-40℃, long-term high temperature operation, light will have an irreversible impact on the efficiency, performance and life of the energy storage system, heavy will cause the risk of thermal runaway, resulting in safety accidents. “

At present, the mainstream heat dissipation methods of battery packs are air-cooled heat dissipation and liquid-cooled heat dissipation.

Air-cooled heat dissipation:

As we all know, there are three ways of heat transfer, namely, heat conduction, heat radiation and heat convection.

Heat conduction refers to the transfer of heat from one part of a system to another or from one system to another. Heat convection is the process of uniform temperature between the hotter and cooler parts of a liquid or gas by circulating flow; Thermal radiation is the outward emission of energy by an object due to its temperature.

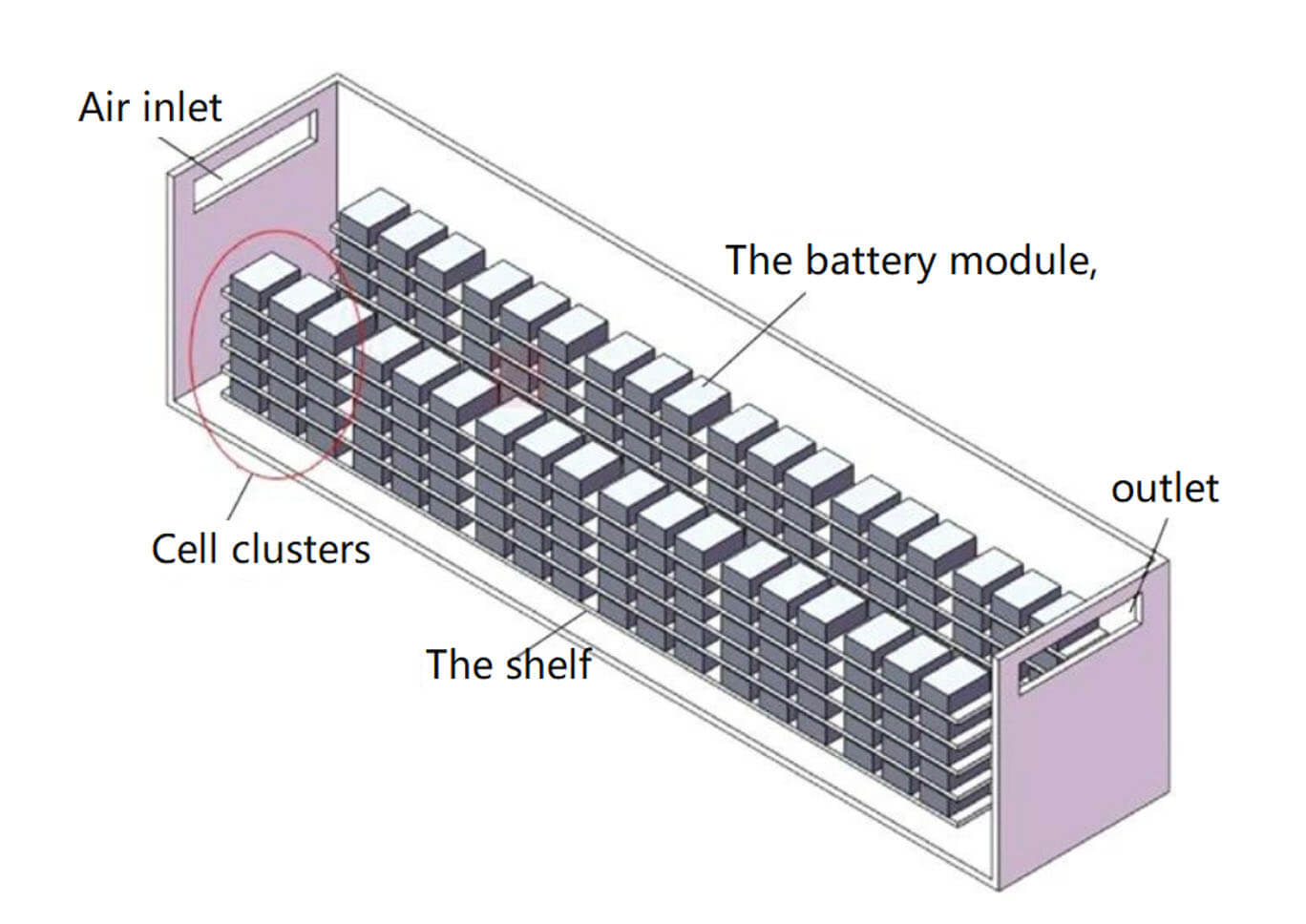

The internal structure of the container-type lithium energy storage system is as follows: The container is 12 m long, 2.4 m wide and 2.8 m high. 12 groups of battery clusters are placed in the battery cabin, with 6 groups placed on each side. Each group of battery clusters consists of 15 battery modules.

Taking cooling as an example, when the temperature of the battery module is increased during the charging and discharging process, the heat is first transferred to the cabin air through thermal radiation, and then the cabin air and the outside air transfer heat through the form of thermal convection to reduce the cabin temperature.

There are two main ways of air convection, natural wind and mechanical wind, air flows into the container from the inlet, and flows out from the outlet after heat exchange.

Low efficiency of natural wind, less use except for specific conditions; The mechanical air needs to be used with the air conditioning system to adjust the air temperature efficiently.

At present, for this heat transfer process, the market focuses on three types of research, one is to change the forced air cooling conditions, the second is to change the air duct design, and the third is to add a deflector in the battery cabin.

Forced air cooling, there are two ways to increase the heat source heat dissipation surface area and speed up the air flow rate per unit time, the former can be achieved by installing a heat sink on the surface of the battery module, the latter can be achieved by installing a fan (fan).

Air ducts include the main air duct connected to the air conditioner outlet, the air baffle in the main air duct, the air baffle at both ends of the air duct, and the air baffle at both ends of the battery rack. The air ducts are arranged in a symmetrical manner based on container characteristics. The design efficiency of existing air ducts is basically high, and it is difficult to further improve them.

The baffle is added in the battery cabin. According to the different number and location of the baffle, the air flow field distribution, temperature distribution and cooling situation in the battery cabin will change.

Liquid cooling heat dissipation:

The liquid cooling heat dissipation is divided into internal circulation and external circulation, the inner circulation is arranged in the battery compartment, and the outer circulation is arranged in the battery compartment.

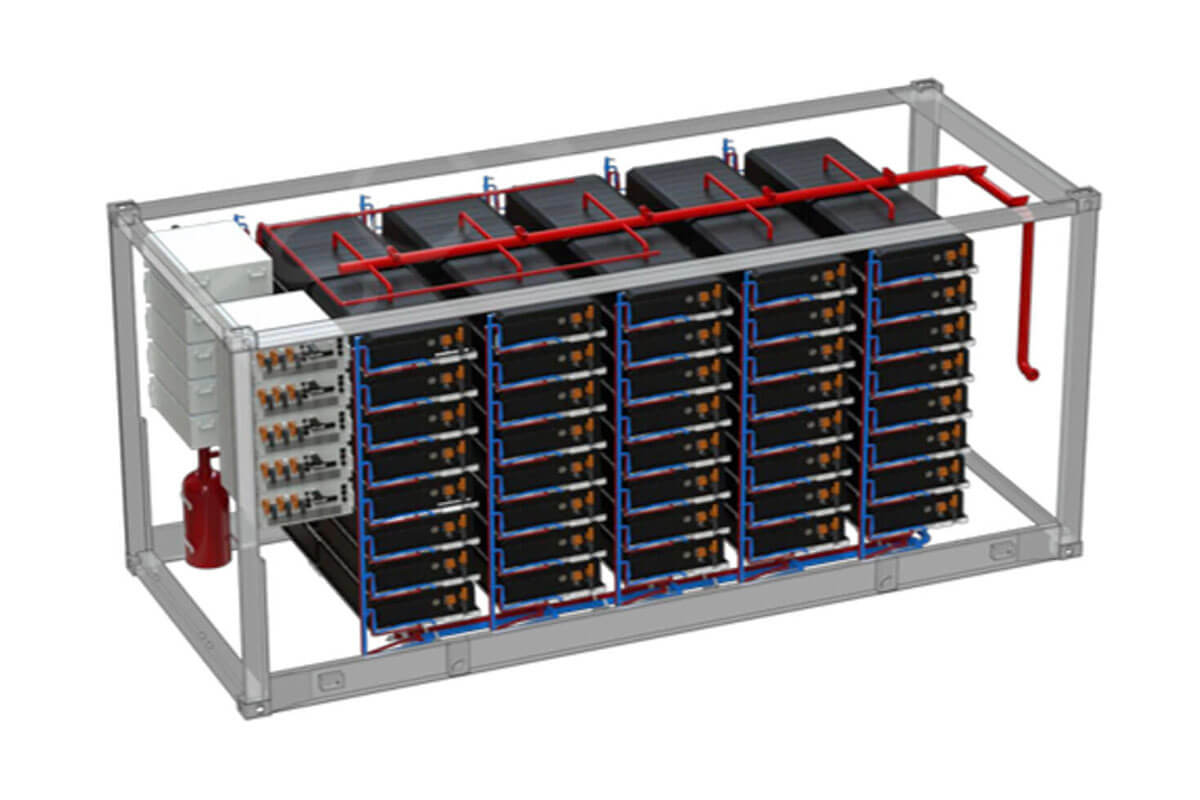

In terms of internal circulation, the battery PACK is in direct contact with the liquid cooling plate, and the heat is transferred from the battery module to the interior of the thermal conductive medium through heat conduction, which flows from the cabin to the outside, and the heat is transferred from the battery cabin to the outside of the battery cabin through thermal convection.

In terms of external circulation, the temperature of the heat conducting medium can be adjusted to an appropriate range through temperature regulating devices such as air conditioners.

There are many differences between liquid cooling heat dissipation and air cooling heat dissipation, such as different heat conduction media and different media circulation devices.

In terms of heat conduction media, the air-cooled heat conduction medium is air, and the types of liquid cooling heat conduction media are more diverse, including water, ethanol, refrigerants and so on. The specific heat of air is 1.4kJ/ (kg*K), and the specific heat of water in the liquid medium is 4.2kJ/ (kg*K), which is three times that of air, so the heat dissipation of liquid cooling is higher than that of air cooling.

In terms of media circulation device, as shown in the figure, liquid cooling heat dissipation needs to run through a main pipe on the energy storage battery system in the container, and each battery cluster is connected with a thinner branch pipe, and each branch pipe is connected with the liquid cooling plate arranged on each battery PACK, and heat is exchanged by changing the type and flow rate of the heat conducting medium in the liquid cooling plate.

There are many forms of liquid cooling plate, including parallel mini runner cold plate, snake-like runner structure cold plate, streamlined runner cold plate, double reversed runner cold plate, parallel divergent runner cold plate and bionic wing vein cold plate, etc. The heat dissipation efficiency is also different in different forms.

Submerged liquid cooling means that the energy storage battery is directly immersed in a special insulating coolant, and the heat generated during the battery charge and discharge process is absorbed by the coolant, and then enters the external circulation for cooling.

In summary, the advantage of liquid cooling is high heat transfer efficiency, the disadvantage is high early cost, suitable for high battery energy density, charge and discharge speed, high power requirements of the energy storage environment.