Introduction

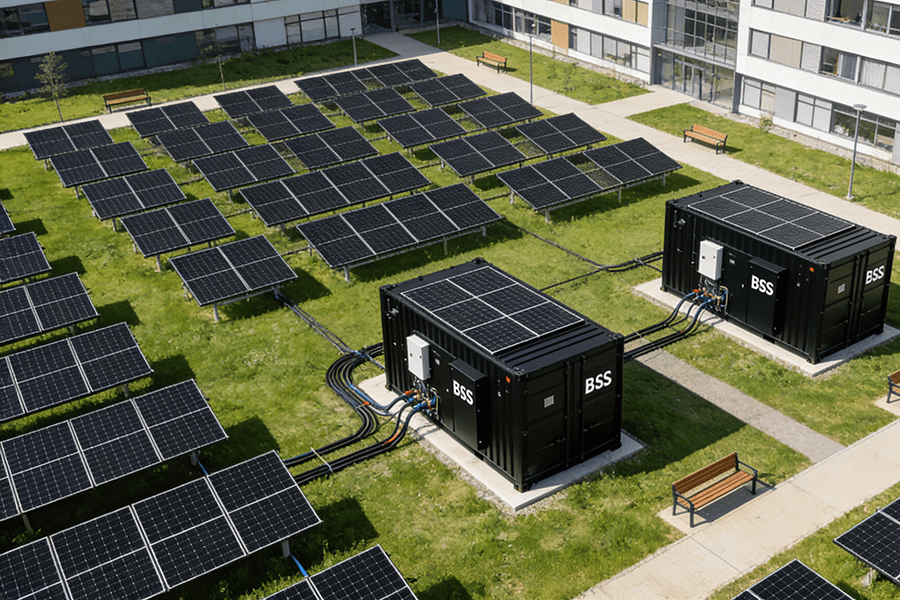

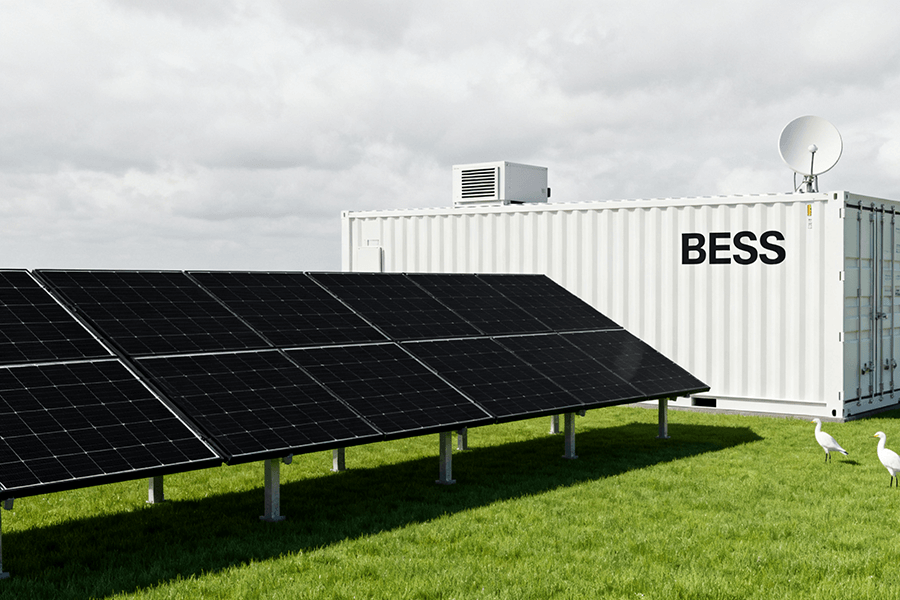

In Europe, sustainable development has undergone a remarkable transformation, evolving from a mere “nice-to-have” concept to a binding legal mandate. This seismic shift places Battery Energy Storage System (BESS) containers at the epicenter of the green transition, thrusting them into a pivotal role in the continent’s energy revolution.

Once regarded as simple, utilitarian “power boxes,” these systems have now emerged as linchpins in the complex process of integrating variable renewable energy sources, such as solar and wind, into the power grid. Their ability to store excess energy during peak production times and release it when demand surges makes them indispensable for maintaining grid stability amidst the growing penetration of intermittent renewables.

The Environmental Conundrum

However, a significant challenge looms large: traditional BESS containers are associated with substantial carbon footprints. In fact, studies have shown that their production and disposal processes can account for up to 25% of their total lifecycle emissions[^1]. This stark reality underscores the urgent need for a reevaluation of the environmental impact of these critical energy storage solutions.

The manufacturing phase alone involves energy-intensive processes, from mining raw materials for battery cells to assembling the containers. Additionally, the lack of standardized recycling infrastructure means that end-of-life BESS containers often end up in landfills, contributing to pollution and resource waste.

Europe’s Ambitious Sustainability Agenda

Europe’s commitment to sustainability is both resolute and ambitious. The continent has set clear, far-reaching targets:

- To slash greenhouse gas (GHG) emissions by at least 55% by 2030, compared to 1990 levels

- To achieve the ultimate goal of net-zero emissions by 2050[^2]

In this ambitious agenda, BESS containers play a crucial, non-negotiable role. Yet, despite their importance, their environmental implications have, until recently, remained largely overlooked. This oversight is now being addressed through a concerted effort across the industry.

The Path Forward: Redefining BESS Containers

This article delves deep into the innovative strategies and initiatives through which European manufacturers, policymakers, and operators are redefining BESS containers. No longer seen merely as functional energy storage tools, these containers are being reimagined as eco-friendly assets—integral components of a sustainable energy future.

We will explore a range of approaches, including:

- Cutting-edge design and manufacturing techniques: Incorporating lightweight materials, modular designs, and energy-efficient production methods

- Novel end-of-life management strategies: Developing circular economy models for battery recycling and container reuse

- Policy and regulatory frameworks: Examining how EU directives are driving the adoption of sustainable practices

Sustainable Production of BESS Containers

Sustainable production serves as the bedrock for environmentally friendly Battery Energy Storage System (BESS) containers. After all, it’s impossible to create a green product using polluting materials or energy-intensive processes. Below is a detailed exploration of the pivotal innovations in materials and manufacturing that are driving the sustainable development of BESS containers in Europe.

Eco-friendly Materials Selection

The era of constructing BESS containers solely from steel is firmly in the past. European manufacturers are now strategically prioritizing materials that strike a delicate balance between durability, performance, and a minimized carbon footprint. Among these, aluminum alloys stand out as a game-changer. This lightweight, highly recyclable alternative to traditional carbon steel is revolutionizing the industry.

| Material Type | Carbon Emission (kg CO₂eq/kg) | Recyclability Rate | Key Application in BESS Containers |

|---|---|---|---|

| Traditional Carbon Steel | 1.8–2.2 | ~70% | Container frames (legacy designs) |

| Aluminum Alloys | 0.5–0.8 | >95% | Container bodies, battery racks |

| Recycled HDPE Plastic | 0.3–0.5 | ~80% | Battery packaging, insulation |

*Data sources: European Aluminium Association / PlasticsEurope *

The advantages of aluminum are clear and compelling. By incorporating aluminum alloys, BESS container weight can be reduced by 30–40%. This significant decrease not only eases the burden on transportation, leading to lower emissions during transit, but also cuts production carbon emissions by up to 50% compared to steel. A prime example of this shift is Finland-based BESS manufacturer Wärtsilä. The company recently made the strategic decision to switch to aluminum alloy frames for its 20-foot containers. As a result, they were able to slash per-unit lifecycle emissions by an impressive 28%.

In addition to aluminum alloys, biodegradable polymers are rapidly gaining ground in the industry. Germany’s BASF, a global leader in chemical innovation, has developed a groundbreaking plant-based plastic specifically for battery casings. This innovative material is designed to decompose efficiently in industrial composting facilities, effectively eliminating plastic waste at the end of a BESS’s lifecycle. This not only addresses the growing concern of plastic pollution but also aligns with the circular economy principles that are increasingly important in sustainable manufacturing.

Green Production Processes

Even the most sustainable materials are rendered less effective without corresponding eco-friendly manufacturing processes. European BESS factories are undergoing a significant transformation, moving away from fossil fuels and wasteful practices towards more sustainable methods. This shift is guided by three core strategies:

- Renewable Energy Power: A growing number of factories across Spain, Germany, and the Netherlands have made the commitment to source 100% of their electricity from renewable sources such as on-site solar or wind installations. Siemens Gamesa’s BESS plant in Hamburg serves as an exemplary model. Equipped with 5,000 rooftop solar panels, the plant is able to power its entire production line with clean energy. This initiative has resulted in a remarkable reduction of 1,200 tonnes of CO₂ in annual Scope 2 emissions, demonstrating the significant environmental benefits of transitioning to renewable energy in manufacturing.

- Lean Manufacturing: Dutch firm Eneco has embraced lean manufacturing principles to optimize its production processes. By meticulously redesigning its assembly line to eliminate “waiting time” between production steps, Eneco has achieved a 20% reduction in material waste and a 15% decrease in energy use. Lean manufacturing also emphasizes the reuse of materials. At most plants, up to 12% of raw aluminum scraps are now recycled back into the production process, further enhancing resource efficiency and reducing waste.

- Water Conservation: Cooling systems play a critical role in battery assembly within BESS factories. To address the environmental impact of water usage, many factories are adopting closed-loop designs for these systems. Sweden’s Northvolt is a prime example of a company leading the way in water conservation. Through its advanced closed-loop cooling system, Northvolt is able to recycle an impressive 95% of its manufacturing water, saving 2 million liters of water annually. This not only conserves a vital resource but also reduces the environmental impact associated with water treatment and disposal.

Sustainable Operation

Even the greenest BESS container will waste energy if operated poorly. Europe’s operators are focusing on two interlinked pillars to combat this inefficiency: cutting energy use and shrinking carbon footprints. These strategies not only align with the continent’s ambitious climate goals but also contribute to long-term cost savings and enhanced competitiveness in the energy storage market.

Energy-Saving Operation Modes

BESS containers consume energy for essential functions such as cooling, monitoring, and grid integration. However, recent technological advancements and smart operational strategies are making them far more energy-efficient:

- Low-Power Monitoring: Traditional monitoring sensors typically consume 5–10 watts (W) of power. In contrast, cutting-edge IoT devices developed by companies like ABB have significantly reduced this energy requirement to just 0.5–1 W. Consider a BESS farm consisting of 50 containers. By adopting these low-power sensors, the farm can save approximately 1,800 kWh annually. This amount of energy is sufficient to power five average European households for an entire year, highlighting the substantial energy savings potential of this technology.

- Adaptive Cooling: Cooling systems are the primary energy consumers in BESS operations, accounting for 60–70% of the total energy use. Thanks to advanced algorithms powered by artificial intelligence (AI), modern BESS containers can now dynamically adjust fan speeds and coolant flow rates based on real-time temperature data and battery load. A study conducted by the renowned Fraunhofer Institute revealed that this adaptive cooling approach can reduce cooling energy consumption by up to 30%. For a 1 MWh container, this translates to annual electricity savings of approximately €1,200, making it a cost-effective and environmentally friendly solution.

- Grid-Aware Charging: BESS containers are increasingly being programmed to charge during off-peak hours, when the carbon intensity of the grid is at its lowest. For instance, in France, the period between 2–6 AM typically sees lower grid carbon emissions. By charging during these hours and discharging during peak demand periods, operators can not only reduce operational costs but also achieve a 15–20% reduction in the container’s carbon footprint. This strategy not only benefits the environment but also helps stabilize the grid by balancing supply and demand.

Carbon Footprint Reduction

Transparency is crucial in the fight against emissions, and the European Union is taking decisive action through the EU Battery Regulation, which came into effect in February 2024. Starting from February 2026, all industrial BESS batteries with a capacity of over 2 kWh will be required to publicly disclose their carbon footprint, encompassing the entire lifecycle from raw material mining to end-of-life operations.

To comply with these regulations and gain a competitive edge in the market, operators are employing the following strategies:

- Carbon Trading: BESS owners participating in the EU Emissions Trading System (ETS) have the opportunity to sell excess carbon credits if they manage to reduce their emissions below their allocated quota. For example, a UK-based BESS farm achieved a remarkable 10% reduction in operational emissions in 2024. As a result, they were able to sell carbon credits worth €35,000, demonstrating how emission reduction efforts can also generate additional revenue streams.

- Carbon Offsetting: For emissions that are difficult to eliminate directly, operators are investing in verified carbon offset projects. Germany’s RWE, a major energy company, has committed to offsetting 100% of its BESS operational emissions. They achieve this by funding reforestation projects in Poland, at a cost of approximately €8 per tonne of CO₂. These offset projects not only help neutralize the environmental impact of BESS operations but also contribute to global efforts to combat climate change.

Sustainable Recycling and Disposal

Europe’s “circular economy” agenda means BESS containers can’t end up in landfills. Aligned with the EU’s broader sustainability goals, the emphasis lies on battery recycling and container reuse—two domains where Europe has established itself as a global frontrunner. This commitment not only minimizes environmental impact but also unlocks economic opportunities through resource recovery.

Battery Recycling Technologies

BESS predominantly utilize lithium-ion batteries, which house valuable metals such as lithium, cobalt, and nickel. These metals can be effectively reused, but the recycling process demands specialized technology. Europe has developed two prominent methods:

- Hydrometallurgy: This technique involves using chemical solutions to dissolve and extract metals from spent batteries. Belgium’s Umicore, a leading player in this field, has mastered this process to achieve remarkable recovery rates. Through hydrometallurgy, Umicore can reclaim 99.9% of lithium and 95% of cobalt from BESS batteries. This approach is notable for its low-emission profile, generating only 1.2 tonnes of CO₂ per tonne of batteries processed. However, it requires meticulous waste management of the chemicals involved to ensure environmental safety.

- Pyrometallurgy: Employing high temperatures ranging from 1,200–1,500°C, pyrometallurgy melts batteries to separate their constituent metals. While simpler in operation compared to hydrometallurgy, it is more energy-intensive, emitting 3.5 tonnes of CO₂ per tonne of batteries. Nevertheless, companies like Sweden’s Stena Recycling have refined this method to optimize metal recovery, achieving a 95% yield for nickel and steel.

The EU has set an ambitious target: By 2030, 70% of lithium-ion batteries, including those used in BESS, must be recycled, representing a significant leap from the current 50% recycling rate. This goal is supported by a comprehensive regulatory framework, including the Battery Regulation, which aims to ensure the sustainable management of batteries throughout their lifecycle.

Container Reuse and Recycling

BESS containers, typically measuring 20–40 feet in length, are engineered to last 15–20 years. However, their utility does not end at the conclusion of this initial lifespan:

- Reuse: Instead of being discarded, old containers are refurbished and repurposed for various applications. In Portugal, retired BESS containers have been revitalized to provide small-scale energy storage for rural schools, enhancing access to reliable power in remote areas. In France, Engie has taken container repurposing to the next level by converting 50 decommissioned BESS containers into microgrids for island communities. This innovative approach not only extends the container’s lifespan but also reduces emissions by 80% compared to building new microgrids from scratch.

- Recycling: For containers that are too damaged to be reused, recycling offers a sustainable solution. Metals are carefully stripped from the containers and recycled, with aluminum recycling being particularly energy-efficient. Recycling aluminum consumes just 5% of the energy required to produce virgin aluminum. To illustrate, recycling a single 20-foot container, which contains approximately 800 kg of aluminum, can save a staggering 10,000 kWh of energy. This not only conserves resources but also significantly reduces the environmental footprint associated with metal production.

Policy and Market Incentives for Sustainable BESS Containers

Europe’s sustainable BESS boom isn’t accidental—it’s driven by policy carrots and market demand.

European Policy Support

Policymakers across Europe have strategically deployed a comprehensive toolkit of incentives and regulations to accelerate the adoption of sustainable Battery Energy Storage Systems (BESS). These initiatives, spanning subsidies, tax breaks, and regulatory mandates, serve as the cornerstone of the continent’s green energy transition.

| Policy Initiative | Region | Incentive Details | Impact & Outcomes |

|---|---|---|---|

| Horizon Europe Funding | EU-wide | A substantial €2.1 billion allocation from 2021–2027 aims to foster R&D in sustainable battery technologies. This funding targets innovations in recycling processes, eco-friendly materials, and energy-efficient designs. | A 2024 European Commission study revealed that BESS projects leveraging Horizon Europe funds achieved an average 34% reduction in production emissions, demonstrating the program’s effectiveness. |

| Corporate Tax Reduction | Sweden | Companies engaged in manufacturing environmentally friendly BESS enjoy a preferential tax rate of 10%, significantly lower than the standard 20.6%. This measure incentivizes investment in green production facilities and R&D. | Swedish manufacturers have reported a 25% increase in sustainable BESS production since the tax reform’s implementation, positioning the country as a regional leader in the sector. |

| Feed-in Tariffs (FiTs) | Germany | BESS systems incorporating over 80% recycled materials receive an additional €0.02/kWh under Germany’s FiT scheme. This financial incentive encourages the use of recycled components and circular economy practices. | The policy has spurred a 40% growth in recycled material usage within German BESS installations, reducing reliance on virgin resources. |

| Extended Producer Responsibility (EPR) | EU-wide | Manufacturers are legally obligated to finance battery recycling initiatives, ensuring proper end-of-life management. This policy promotes accountability and circularity in the BESS supply chain. | EPR implementation has led to a 60% increase in battery recycling rates across the EU, minimizing environmental impacts from discarded batteries. |

Market Demand for Green Products

The market landscape for BESS in Europe is undergoing a profound transformation, with sustainability emerging as a decisive factor in purchasing decisions. Investors, businesses, and consumers alike are increasingly aligning their choices with environmental objectives, driving significant shifts in industry dynamics.

Premium for Green Labels

Products bearing the EU Ecolabel—a prestigious certification awarded to goods with minimal lifecycle emissions—command a notable price premium. This certification serves as a trusted indicator of environmental performance, enabling buyers to differentiate between sustainable and conventional BESS solutions.

| Certification | Price (per 1 MWh) | Premium Percentage |

|---|---|---|

| EU Ecolabel Certified | €180,000 | 15–20% |

| Non-Certified | €150,000 | – |

Investor Pressure

Institutional investors are wielding their influence to drive sustainability in the BESS sector. Approximately 70% of major European investors, including industry giants like BlackRock and APG, now mandate BESS suppliers to disclose detailed carbon footprint data. Non-compliance can have severe consequences, as illustrated by a UK-based firm that lost a £50 million project in 2024 due to insufficient recycling data.

Consumer Demand

Businesses across Europe are prioritizing sustainability in their procurement strategies. A McKinsey survey highlighted a remarkable shift, with 70% of European companies now ranking sustainability as a top criterion when purchasing BESS—up from just 45% in 2020. This trend is primarily fueled by corporate net-zero targets, as 85% of Fortune 500 companies operating in Europe now require suppliers to meet stringent eco-standards. These developments underscore the growing importance of environmental stewardship in the BESS market, signaling a fundamental shift towards a more sustainable future.

Conclusion: The Road Ahead for European BESS Sustainability

Europe’s BESS container industry is at a turning point. Sustainable production (aluminum, renewables), smart operation (AI cooling, grid-aware charging), and circular recycling (hydrometallurgy, container reuse) are no longer “innovations”—they’re table stakes.

Policy support (Horizon Europe, EPR) and market demand (green premiums, investor pressure) will accelerate this shift. By 2030, we expect 80% of new European BESS containers to be Ecolabel-certified, with lifecycle emissions cut by 50% vs. 2025 levels .

Our Role at Maxbo Solar

At Maxbo Solar (www.maxbo-solar.com), we’re not just following this trend—we’re leading it. Here’s how we’re contributing to Europe’s sustainable BESS journey:

- Eco-Materials: We use 100% recycled aluminum for our container frames, cutting production emissions by 40% vs. industry averages.

- Green Production: Our factory in Hungary runs on 100% on-site wind and solar, with zero waste sent to landfills (we recycle 98% of manufacturing scraps).

- Recyclable Design: All our BESS containers are built for easy disassembly—batteries can be removed in 2 hours, and 95% of components are recyclable.

- EU Compliance: We already meet the 2026 EU Battery Regulation carbon footprint requirements, and all our products are EU Ecolabel-eligible.

We’re proud to partner with European utilities, cities, and businesses to build a net-zero future. Whether you need a 1 MWh container for a solar farm or a microgrid solution for a rural community, Maxbo Solar’s sustainable BESS systems deliver performance and planet-friendly results. Visit our website to learn more—or reach out to our team to discuss your project.