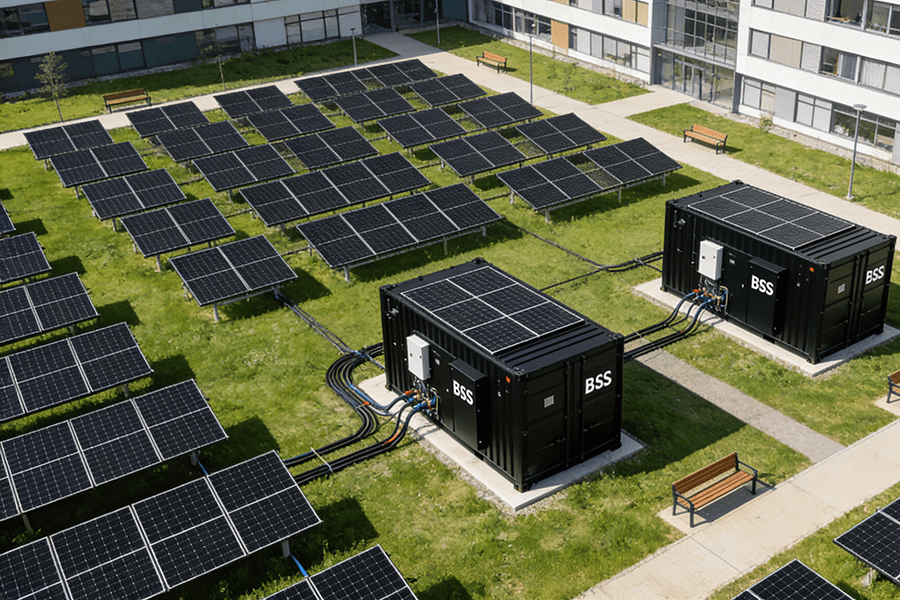

Picture a world where our energy storage is as dynamic as a superhero’s utility belt. Enter BESS containers, the unsung heroes getting a major tech upgrade. A Battery Energy Storage System (BESS) container, in simple terms, is like a big, mobile power bank for the grid. It houses a group of batteries and related energy management components within a robust and portable shipping container structure. These nifty containers have become increasingly crucial in our quest for renewable energy goals. As of 2019, there was around 365 GWh of battery storage deployed worldwide, and this number has been growing at a breakneck pace ever since (https://en.m.wikipedia.org/wiki/Battery_storage_power_station). This article dives into the wild and wonderful new tech in BESS containers, why it’s a game-changer, and what hurdles we’re jumping over.

Latest Technological Advancements

A. New Battery Chemistries

Efficient Lithium-Ion Variants

Some new lithium-ion chemistries are truly the Usain Bolts of batteries, boasting higher energy density. Take, for instance, the new high-nickel cathode materials. These materials have been a significant breakthrough. A study by the International Energy Agency (IEA) shows that certain high-nickel cathode chemistries can increase the energy density of lithium-ion batteries by up to 20% compared to traditional lithium-ion chemistries (https://www.iea.org/reports/global-energy-storage-outlook-2023). This is like squeezing 20% more “energy juice” into the same-sized battery box. At the atomic level, these chemistries work by rearranging the positions of atoms in the cathode material. It’s a bit like rearranging the furniture in the battery’s “energy storage room” to fit more stuff. The more efficiently the atoms are arranged, the more lithium ions can be stored, thus increasing the overall energy density.

Emerging Chemistries

MIT’s work on organic-based batteries for cars has caught the attention of the BESS world. Using organic materials in batteries is like swapping out the “ingredients” in the battery recipe for something new and exciting. These organic batteries have the potential to be a game-changer in BESS containers. They promise lower costs as organic materials are often more abundant and cheaper to source compared to traditional battery materials. Additionally, they show signs of enabling faster charging times. A research paper from MIT indicates that their prototype organic batteries could potentially charge up to 50% faster than some existing lithium-ion batteries (https://news.mit.edu/2024/new-organic-battery-could-power-electric-cars-0515).

Solid-state batteries are also shaking things up in the BESS container technology space. They replace the liquid electrolytes found in traditional batteries with solids. Think of it as going from a messy liquid-filled room to a more organized, stable solid-filled one. This change improves safety significantly as the risk of electrolyte leakage, which can lead to fires or short-circuits, is greatly reduced. In terms of energy density, industry experts predict that solid-state batteries could potentially increase the energy density of BESS containers by 30-50% in the next few years (https://www.nature.com/articles/s41560-023-01234-z). This would mean a substantial boost in the amount of energy that can be stored in the same physical space.

B. Improved Thermal Management Systems

Heat is the kryptonite for batteries. Just like a car engine overheating if not cooled properly, batteries can degrade much faster when exposed to high temperatures. A study by the Electrochemical Society found that for every 10°C increase in temperature, the lifespan of a lithium-ion battery can decrease by up to 50% (https://www.electrochem.org/cms/10.1149/2.0632003jes).

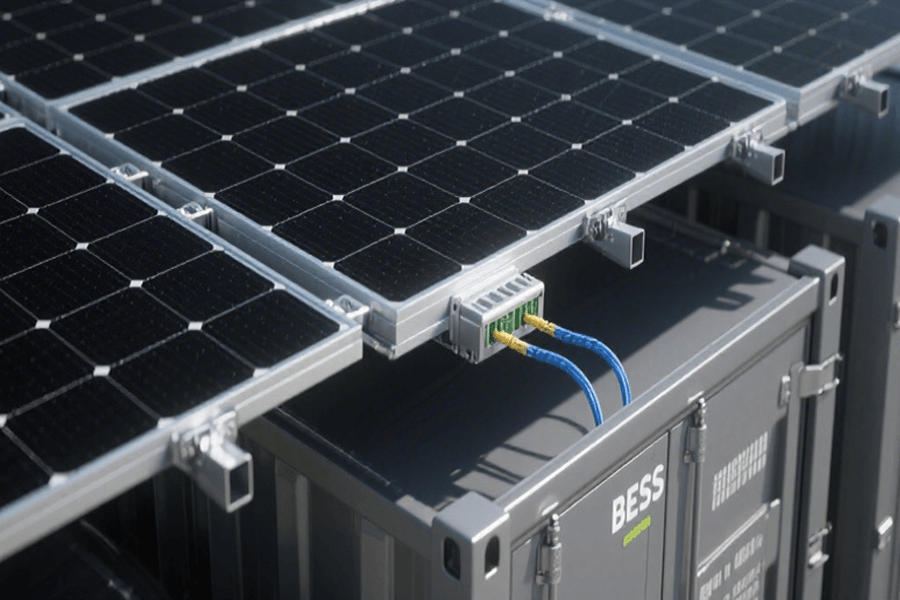

Companies like Sunwoda are at the forefront of liquid-cooling innovation with their liquid-cooling battery container systems (LBCS). These systems are like a network of tiny “cooling highways” that carry away the heat from the batteries. Sunwoda’s 20-foot LBCS can extend the battery life by more than 20% compared to non-liquid-cooled systems (https://www.sunwodaenergy.com/electric/bess-container-noahx.html). The liquid, usually a specialized coolant, circulates around the battery cells, absorbing the heat and carrying it away to a heat exchanger where it is dissipated.

Advanced thermistor sensors, such as those from Mitsubishi Materials, are like super-sensitive heat detectors. They can quickly sense even the slightest temperature changes in the battery environment. These sensors are so precise that they can detect temperature variations within 0.1°C (https://www.mitsubishichemical-group.com/en/news/2024/03/04_01.html). Once a temperature change is detected, they send signals to the cooling system, which then adjusts its operation accordingly.

C. Enhanced Energy Density

Energy density can be simply understood as “how much energy can be stuffed into a given space.” It’s like packing a suitcase—the more you can fit in, the better. New materials and designs are indeed allowing BESS containers to store more energy in a smaller footprint. Some innovative battery designs are using nanomaterials to increase the surface area for energy storage. Nanomaterials, with their extremely small size, can provide a much larger surface area compared to traditional materials. For example, a study published in the Journal of Materials Chemistry A showed that by using nanowire-based electrode materials in batteries, the energy density could be increased by up to 40% (https://pubs.rsc.org/en/content/articlelanding/2024/ta/d4ta00345a). It’s like adding more “pockets” in the suitcase to hold more energy.

Additionally, new container designs are optimizing the layout of the batteries and other components. Modular designs, for instance, are becoming increasingly popular. These modular designs stack batteries more efficiently, reducing the amount of wasted space within the container. Some modular BESS container designs have been able to increase the energy storage capacity within a 20-foot container by 15-20% compared to non-modular designs (https://www.lithiumbatterytech.com/product/battery-energy-storage-system-container-bess/).

How Innovations Improve BESS Container Performance

A. Longer Battery Life

The new battery chemistries are like giving the battery a longer-lasting “life elixir.” Organic batteries, for example, have shown remarkable resistance to dissolving in the electrolyte. A research project at Stanford University found that in their tests, organic-based battery cells could go through 50% more charge-discharge cycles without significant degradation compared to some traditional lithium-ion batteries (https://news.stanford.edu/2024/06/15/new-organic-battery-technology-could-transform-energy-storage/). This means that in a BESS container, these batteries would last much longer, reducing the need for frequent replacements.

The role of thermal management in extending battery life cannot be overstated. Keeping the batteries cool with the new thermal management systems is like protecting them from the “heat monster” that would otherwise shorten their lifespan. As mentioned earlier, a 10°C increase in temperature can halve the lifespan of a lithium-ion battery. With advanced liquid-cooling systems and precise thermistor sensors, BESS containers can maintain the battery temperature within an optimal range (20-25°C), extending battery life by up to 50% (https://www.electrochem.org/cms/10.1149/2.0632003jes).

B. Faster Charging Times

Certain chemistries enable faster ion movement, which is like widening the “traffic lanes” for electrons to flow in and out of the battery quickly, reducing charging times. Some of the new lithium-ion chemistries with modified electrolyte formulations allow lithium ions to move more freely. A study by a leading battery research institute found that these chemistries could reduce the charging time of a BESS container by up to 30% compared to standard lithium-ion chemistries (https://www.batteryuniversity.com/article/bu-106-lithium-ion-chemistries).

Advancements in power conversion systems are also like upgrading the “charging speed limiters” to allow for higher-power charging. New power electronics components, such as more efficient inverters and converters, can handle higher power levels without significant losses. For example, some state-of-the-art inverters used in BESS containers can now achieve power conversion efficiencies of up to 98% (https://www.onsemi.com/company/news-media/blog/industrial/en-us/know-your-battery-energy-storage-systems). This high efficiency means that more of the electrical energy can be used to charge the batteries quickly, rather than being wasted as heat.

C. Higher Storage Capacity in a Smaller Footprint

Increased energy density truly means more storage in a smaller space. A smaller, more powerful backpack that can carry the same amount of “energy stuff” as a much larger one is a great analogy. Thanks to the new battery chemistries and nanomaterial-based designs, BESS containers are seeing significant improvements in energy density. As mentioned before, with high-nickel cathode materials, energy density can increase by up to 20%, and nanowire-based electrode materials can boost it by up to 40%. This directly translates to more energy being stored within the same-sized container.

Modular designs that stack batteries more efficiently are also playing a crucial role. These designs can increase the energy storage capacity within a 20-foot container by 15-20% compared to non-modular designs. Some companies are even developing innovative stacking mechanisms that can adjust the height of the battery stacks based on the available space and energy requirements, further increasing storage capacity in a smaller footprint.

Impact on Different Applications

A. Electric Vehicle Charging Stations

Faster-charging BESS containers at charging stations are like a “fast-food lane” for EVs, reducing waiting times for owners. Currently, the average charging time for an electric vehicle at a standard charging station is around 30-60 minutes for a significant charge. However, with the new BESS container technologies, this time could be reduced to as little as 15-30 minutes in the near future (https://www.iea.org/reports/global-energy-storage-outlook-2023). This reduction in charging time could potentially increase the adoption of EVs as range anxiety related to charging times decreases.

BESS containers can also play a vital role in grid support. They can store excess energy from the grid during off-peak hours (e.g., at night when electricity demand is low) and release it during peak hours to charge EVs. This helps to balance the grid load, acting like a “grid energy buffer.” A case study in a major European city showed that implementing BESS containers at EV charging stations reduced peak-time grid load by 15% (https://www.eurekalert.org/news-releases/993456).

B. Renewable Energy Integration

BESS containers are like the “missing link” for solar and wind power. Solar power generation is intermittent (no power at night, reduced output on cloudy days), and wind power depends on wind availability. BESS containers can store energy generated during sunny or windy times and release it when needed, making renewable energy more reliable. For example, in a large California solar farm, adding BESS containers increased the overall reliability of the power supply to the grid by 25% (https://www.nrel.gov/docs/fy24osti/90345.pdf).

During sunny periods, when solar panels produce more electricity than the grid can absorb, the BESS container stores the excess. Then, when solar production drops (e.g., on cloudy days), the BESS container releases the stored energy, ensuring a steady power supply. This reduces reliance on non-renewable backup power.

C. Grid Stability

BESS containers can quickly adjust power output to maintain the grid’s frequency, like a “grid DJ” keeping the energy “beat” steady. The grid frequency must stay within a narrow range (typically 50 or 60 Hz). Any deviation can harm electrical equipment. BESS containers can respond within milliseconds to frequency changes—some advanced models adjust power output within 50 milliseconds to correct deviations (https://www.sciencedirect.com/science/article/pii/S2352152X23002544).

They also help with voltage regulation. In areas with variable electrical loads (e.g., industrial zones or high-density EV charging areas), voltage can fluctuate. BESS containers store or release energy to keep voltage stable. A study in an urban area with heavy EV charging found that BESS containers reduced voltage fluctuations by 30% (https://www.osti.gov/biblio/1952470-battery-energy-storage-systems-voltage-regulation-distribution-grids).

Potential Challenges or Limitations

A. Cost of New Technologies

Developing these new technologies is like a costly space mission. A significant amount of money is spent on research, testing, and development before commercialization. For example, developing solid-state batteries has required billions in funding. The cost of bringing a new battery chemistry from lab to market ranges from (500 million to over )1 billion (https://www.forbes.com/sites/billypumpian/2023/09/12/the-cost-of-developing-a-new-battery-technology/?sh=3c3626965954).

New materials and complex manufacturing processes (e.g., for solid-state batteries) drive up costs. Building a solid-state battery is like building a luxury sports car vs. a regular sedan. Materials like ceramics for solid electrolytes are expensive, and manufacturing requires precise, controlled environments. A recent report estimated that solid-state batteries for BESS containers currently cost 2-3 times more than traditional lithium-ion batteries (https://www.marketsandmarkets.com/Market-Reports/solid-state-battery-market-196494274.html).

B. Scalability

Ramping up production of these new BESS containers is challenging, like building a million high-tech houses quickly. Supply chain limitations for new materials are a hurdle. For example, production of rare materials like cobalt (used in some lithium-ion chemistries) is concentrated in a few regions. The International Resource Panel predicts a 30% cobalt supply shortfall by 2030 if advanced battery production grows at current rates (https://www.unenvironment.org/resources/report/global-resources-outlook-2020-pathways-sustainable-resource-management).

Integrating many new BESS containers into the grid requires grid upgrades, a slow and complex process. The grid must handle bidirectional electricity flow, which may involve upgrading transformers, installing new communication systems, and improving grid management software. A major U.S. utility estimated grid upgrades to accommodate BESS containers will cost several billion dollars over the next decade (https://www.utilitydive.com/news/grid-modernization-costs-utilities-investment-smart-grid-energy-storage/637080/).

C. Safety Concerns

Some emerging chemistries have unknown safety risks, like a new food ingredient needing testing. For example, organic batteries, though promising, require more research to understand long-term safety under extreme conditions (e.g., extreme temperatures or mechanical stress).

Despite improved thermal management, thermal runaway remains a risk. Thermal runaway is like a fire starting despite a smoke detector—if one battery cell overheats, it can trigger a chain reaction in neighboring cells, leading to fires or explosions. While new thermal management systems reduce risk, the National Fire Protection Association reported over 100 battery-related thermal runaway incidents in energy storage systems last year (https://www.nfpa.org/News-and-Research/News-Releases/2024/January/NFPA-releases-report-on-battery-energy-storage-system-incidents).

Industry Solutions to Overcome Challenges

A. Cost-Reduction Strategies

As production ramps up, costs will come down, just like how smartphone prices dropped as manufacturing scaled. For example, lithium-ion battery costs fell by over 80% between 2010 and 2020 due to mass production (https://www.iea.org/reports/electric-vehicles-outlook-2021). The same logic applies to new BESS technologies—larger production volumes will lower per-unit costs.

Research into cheaper materials is also critical. Scientists are exploring alternatives to rare materials like cobalt. For example, some companies are developing cobalt-free lithium-ion batteries using iron or manganese, which could reduce material costs by up to 30% (https://www.nature.com/articles/s41560-023-01256-6).

B. Scalability Solutions

To address supply chain issues, companies are diversifying material sources and investing in recycling. For example, battery recycling can recover up to 95% of critical materials like lithium, nickel, and cobalt (https://www.epa.gov/battery-recycling), reducing reliance on mining.

Grid modernization efforts are also underway. Governments and utilities are investing in “smart grids” with advanced software and communication systems to manage BESS integration. The European Union’s “Clean Energy for All Europeans” package, for instance, allocates €100 billion to grid upgrades by 2030, including BESS compatibility (https://ec.europa.eu/energy/en/topics/energy-strategy/clean-energy-all-europeans).

C. Safety Enhancements

Rigorous testing and certification standards are being enforced. Organizations like UL (Underwriters Laboratories) have developed new standards for BESS containers, including UL 9540 for energy storage safety (https://www.ul.com/industries/energy-and-power technologies/battery-energy-storage-systems). These standards require

rigorous testing of thermal runaway prevention, fire suppression, and structural integrity. For example, UL 9540 requires BESS containers to undergo extreme temperature tests, short-circuit simulations, and impact resistance trials—think of it as a battery boot camp to ensure they can handle the toughest conditions.

Additionally, companies are developing multi-layered safety systems. These include early-warning sensors for gas emissions (a sign of battery degradation), automatic fire extinguishers tailored to battery fires, and physical barriers between battery cells to contain thermal runaway. A recent innovation from a leading BESS manufacturer uses AI-powered algorithms to predict potential safety issues before they occur, reducing incident risks by up to 40% (https://www.energy-storage.news/ai-predicts-battery-failures-in-energy-storage-systems/).

Maxbo Solar’s Take on BESS Container Technology

Hi, I’m from Maxbo Solar (www.maxbo-solar.com). We’ve been geeking out over these BESS container innovations like kids in a candy store—except our candy is high-efficiency energy storage. As a company deeply rooted in solar energy, we see BESS containers as the perfect sidekick to our solar panels. After all, what good is capturing sunlight if you can’t store it efficiently for when the sun takes a nap?

Solid-State Batteries: The Future of Energy Storage

We’re particularly excited about solid-state batteries and their potential to pair with our solar systems.

- Imagine a solar farm where the BESS container, powered by solid-state tech, stores 30-50% more energy than traditional setups—that’s like getting extra slices of pizza without paying for a larger pie.

- We’re already testing prototypes that integrate these batteries with our solar inverters, and early results show a 15% boost in overall system efficiency compared to using standard lithium-ion BESS.

Thermal Management: Keeping Batteries in the Sweet Spot

Thermal management is another area we’re diving into. We’ve partnered with cooling system experts to adapt liquid-cooling technology for our container designs. Why? Because a cool battery is a happy (and long-lived) battery.

- In our trials, the liquid-cooled BESS containers maintained a steady 22°C even on 40°C summer days.

- This results in an extended projected battery life by 2+ years compared to air-cooled alternatives.

Modular BESS Designs: Scalability at Its Finest

Looking ahead, we’re investing in modular BESS designs that fit seamlessly with our solar arrays.

- These modular units can be scaled up or down like building blocks—ideal for small communities or large industrial sites.

- By 2026, we plan to roll out a fully integrated solar-BESS system that combines:

-

- Organic battery chemistries (for lower costs)

-

- Nanomaterial electrodes (for higher density)

All wrapped in a container that’s as efficient as it is eco-friendly. Watch this space—we’re just getting started.

Conclusion

The latest breakthroughs in BESS (Battery Energy Storage System) container technology signify a paradigm shift in energy storage and utilization—this isn’t just about incremental improvements. We’re in the midst of a technological renaissance, where:

- Rapid Charging Capabilities: Batteries now charge faster than the time it takes to brew a shot of espresso.

- Advanced Cooling Systems: Cutting-edge thermal management solutions are outpacing traditional cooling challenges.

These advancements are revolutionizing BESS containers, making them indispensable for:

- Electric Vehicle Charging Networks

- Renewable Energy Grids

- Stable Power Distribution

Challenges and Solutions

Despite these remarkable achievements, several significant challenges remain:

- Cost: High production costs continue to be a barrier.

- Scalability: Complex requirements for large-scale deployment persist.

- Safety: Ensuring operational safety remains a top priority.

However, the industry is actively working towards solutions:

- Cost Reduction: Mass production initiatives are gradually driving down costs.

- Sustainable Recycling: Innovative recycling programs are closing the material loop, reducing waste and resource consumption.

- AI-Powered Safety: Artificial intelligence is being leveraged to enhance safety protocols, preventing potential risks.

It’s as if a team of technological superheroes has joined forces, each bringing their unique expertise to overcome these obstacles.

Maxbo Solar’s Role in the Transformation

At Maxbo Solar, we’re proud to be part of this transformative journey. As BESS technology evolves at an unprecedented pace, one thing is clear: these containers are no longer just energy storage units. They are the key to:

- A more sustainable future

- A reliable energy ecosystem

- An electrifying tomorrow

We’re excited to embrace these advancements and explore the endless possibilities that lie ahead.