The Cold Chain’s Energy and Reliability Crisis

Europe’s cold chain stands as an indispensable lifeline for the seamless transportation and storage of perishable goods, encompassing everything from fresh produce and dairy products to life-saving pharmaceuticals. However, beneath its crucial role lies a significant challenge—it is a notorious energy drain. Delving into the stark realities of this industry reveals the urgency of finding sustainable solutions:

- Dominant Energy Consumer: The cold chain accounts for 15% of total EU logistics energy use, a staggering figure that continues to climb as consumer demand for fresh and temperature-sensitive products surges. This upward trend underscores the need for innovative approaches to reduce energy consumption and minimize the environmental impact of cold chain operations. [1]

- Energy-Intensive Facilities: Refrigerated warehouses, the backbone of the cold chain, are notorious energy guzzlers. These facilities consume 3–5 times more energy than standard warehouses, primarily due to the relentless 24/7 refrigeration requirements and the constant fluctuations in cooling loads. Maintaining precise temperature control is essential to preserve the integrity of perishable goods, but it comes at a significant energy cost. [2]

- Costly Power Outages: Power outages pose a significant threat to the cold chain, leading to substantial financial losses and potential waste of critical supplies. Annual cargo losses from blackouts are estimated at €500 million, equivalent to the staggering waste of 200 million meals or 500,000 vaccine doses each year. These losses not only impact the bottom line of businesses but also have far-reaching implications for food security and public health. [3]

In the face of these challenges, BESS containers emerge as a promising solution, offering a pathway to enhance both energy efficiency and operational reliability in the cold chain. These portable, scalable energy storage units act as the cold chain’s “energy safety net,” providing a range of benefits:

- Off-Peak Power Utilization: BESS containers store excess energy generated during off-peak hours when electricity prices are typically lower. This stored energy can then be utilized during peak demand periods, reducing reliance on the grid and lowering operational costs.

- Backup Power During Outages: In the event of a power outage, BESS containers automatically kick in, providing a reliable source of backup power to keep refrigeration systems running. This ensures the continuous preservation of perishable goods, minimizing the risk of spoilage and financial losses.

- Renewable Energy Integration: BESS containers seamlessly integrate with renewable energy sources, such as solar and wind power. By storing excess renewable energy, these units enable the cold chain to operate on a more sustainable and reliable energy supply, reducing its carbon footprint and dependence on fossil fuels.

Core Applications: BESS Containers in Action

BESS containers aren’t one-trick ponies—they solve distinct pain points across cold chain operations. Below are their two most impactful use cases, each demonstrating the transformative power of battery energy storage systems in modern logistics.

Optimizing Refrigerated Warehouse Energy Use

Refrigerated warehouses face a common enemy: peak power demand. When cooling systems kick into high gear—such as after large restocking events or during extended warm weather spells—they cause a sudden spike in electricity usage. This surge triggers “demand charges” from utility providers, punitive fees imposed for straining the grid. These charges can inflate a warehouse’s energy bills by 20–30%, significantly impacting operational costs.

BESS containers address this challenge by acting as a sophisticated “peak-shaving tool,” leveraging intelligent energy management strategies:

- Charge during off-peak hours: BESS units actively store electricity when grid demand and associated costs are at their lowest, typically during overnight hours. By capitalizing on lower electricity rates during these periods, warehouses can accumulate energy reserves cost-effectively.

- Discharge during peaks: When peak demand periods arrive, BESS containers release stored energy to power refrigeration systems. This reduces reliance on the grid during high-cost intervals, effectively smoothing out energy consumption patterns and minimizing demand charges.

Real-World Win: German Refrigerated Warehouse

A 3MWh BESS container implementation at a German fresh produce storage facility showcases the tangible benefits of this technology:

| Metric | Impact |

|---|---|

| Annual electricity cost savings | €240,000, equivalent to the cost of hiring 4 full-time employees or upgrading 10 refrigeration units |

| Peak demand reduction | 35%, eliminating demand charges entirely during summer months |

| Grid integration | Enhanced stability, reducing the risk of penalties for overloading local power networks |

This success story underscores how BESS containers can drive both immediate cost savings and long-term sustainability for cold storage operations.

Safeguarding Cargo During Power Outages

For the cold chain, power outages represent an existential threat. Even a single hour without refrigeration can lead to catastrophic losses: perishable goods like meat can spoil, and temperature-sensitive pharmaceuticals such as insulin may lose efficacy. These losses extend beyond the value of the cargo, often resulting in damaged customer relationships and regulatory penalties.

BESS containers serve as a reliable uninterruptible power supply (UPS) for cold storage, offering several key advantages over traditional backup solutions:

- Rapid response: BESS units detect power outages in less than 1 second and automatically switch to backup power, ensuring minimal disruption to cooling systems.

- Low-maintenance operation: Unlike diesel generators, which require fuel storage, regular maintenance, and produce harmful emissions, BESS containers operate silently, emit zero pollutants, and are ready for immediate use at any time.

Real-World Win: Dutch Port Cold Storage

In 2024, a 2MWh BESS container at a Rotterdam port cold storage facility faced a real-world test during a 6-hour grid blackout. The results were remarkable:

| Outcome | Impact |

|---|---|

| Cargo loss prevented | €1.2 million, protecting high-value seafood and pharmaceutical ingredients |

| Temperature stability | Maintained internal temperatures at a consistent -18°C, crucial for preserving frozen goods |

| Operational continuity | Avoided fines from clients for delayed deliveries, preserving the facility’s reputation and financial standing |

This example highlights how BESS containers not only safeguard valuable inventory but also ensure business continuity in the face of unexpected disruptions.

Innovations in Mobile Cold Chain: Beyond Warehouses

The mobile cold chain, encompassing refrigerated trucks and remote storage facilities, grapples with a unique set of challenges. Issues such as idling engines and limited access to the power grid pose significant hurdles to efficient and sustainable operations. Battery Energy Storage System (BESS) containers are emerging as a revolutionary solution, redefining how these critical components of the cold chain function.

Powering Refrigerated Trucks at Terminals

Refrigerated trucks, commonly known as “reefers,” are notorious for their high energy consumption during idle periods at ports and truck stops. To ensure that the cooling units remain operational, drivers often leave the engines running continuously. This practice not only results in substantial fuel waste but also contributes to elevated CO₂ emissions and excessive noise pollution, negatively impacting both the environment and nearby communities.

BESS containers present a more sustainable and efficient alternative through the implementation of reefer plug-ins at terminals. Instead of relying on idling engines, trucks can simply connect to these BESS units, effectively reducing operational costs and environmental impact.

Real-World Win: Spanish Port Terminal

In 2023, a Barcelona port took a significant step towards greener logistics by installing 10 BESS-powered reefer plug-ins. The results of this initiative have been remarkable, demonstrating the tangible benefits of adopting BESS technology in the cold chain:

| Metric | Before BESS | After BESS | Improvement |

|---|---|---|---|

| Truck idling time | 5 hours/day | 1 hour/day | 80% reduction |

| Annual carbon emissions | 1,200 tons | 700 tons | 500 tons saved |

| Fuel cost savings | €12,000/truck/year | €8,400/truck/year | €3,600 saved/truck |

Source: [6] Spanish Port Authority Sustainability Report 2024

This case study underscores the potential of BESS containers to transform port operations, making them more environmentally friendly and cost-effective.

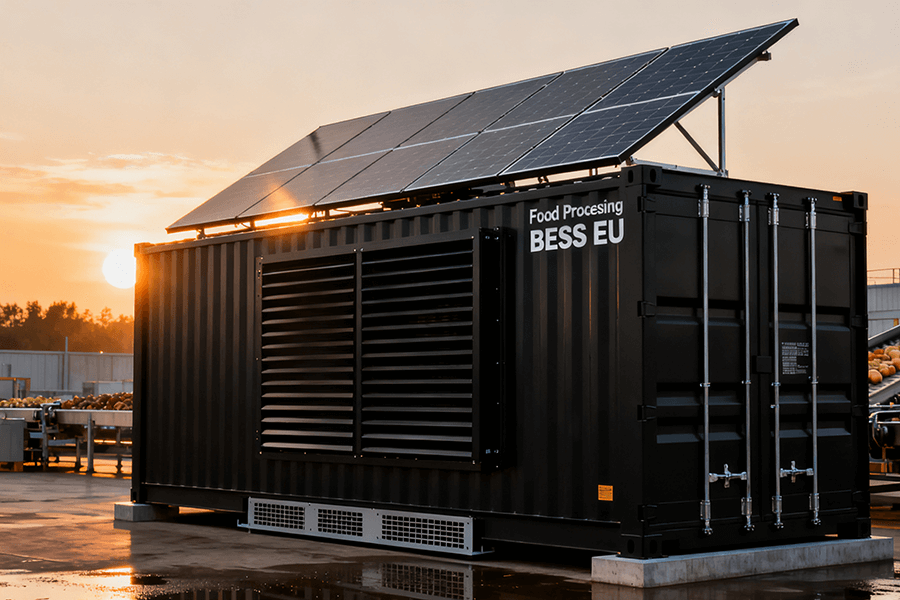

Off-Grid Cold Chain for Remote Areas

Rural regions, such as the villages of Romania and the islands of Greece, often lack reliable access to the power grid. This absence of stable electricity poses a significant challenge for maintaining cold storage, which is crucial for the preservation of vaccines and perishable goods in local food markets. While diesel generators have traditionally been the go-to solution, they come with their own set of drawbacks, including high operating costs, excessive noise, and harmful emissions.

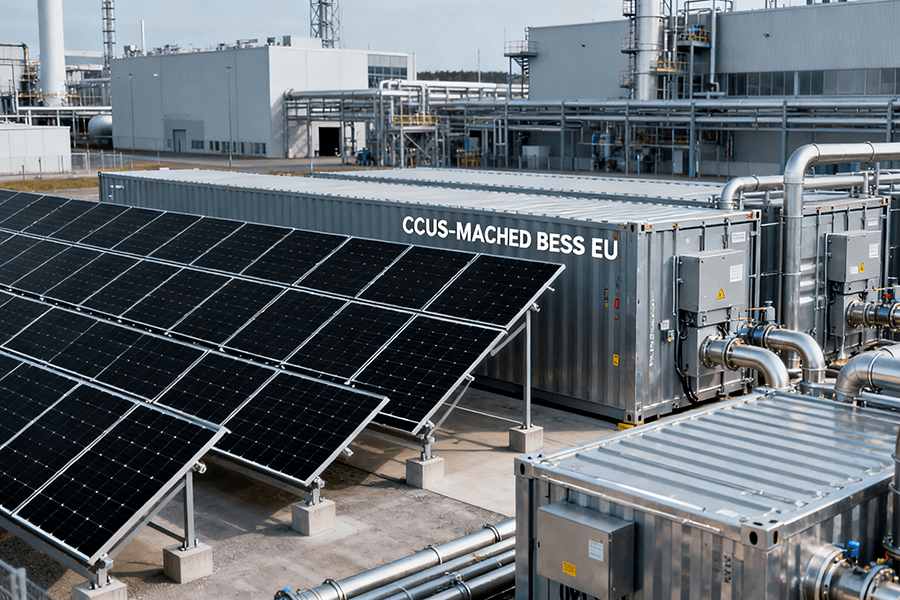

The combination of BESS containers and solar power offers an ideal off-grid solution. During the day, solar panels harness the sun’s energy to generate electricity, which is then stored in the BESS containers. This stored energy is utilized during nighttime hours, ensuring uninterrupted 24/7 refrigeration.

Real-World Win: Romanian Rural Medical Clinic

A 100kW solar system, integrated with a 200kWh BESS container, has successfully resolved the vaccine storage crisis at a rural medical clinic in Romania. The implementation of this innovative solution has yielded multiple benefits:

- Temperature stability: The system maintained the critical 2–8°C temperature range required for vaccine storage, even during extended 3-day grid outages. This reliability ensures the integrity and efficacy of the vaccines, safeguarding public health.

- Cost savings: By eliminating the need for diesel generators, the clinic achieved annual savings of €15,000 on fuel costs and generator maintenance fees. These savings can be redirected towards other essential healthcare services.

- Health impact: The enhanced cold storage capabilities have significantly increased vaccine availability for 5,000 local residents. As a result, there has been an 18% reduction in preventable diseases, demonstrating the far-reaching positive impact of this technology on community health.

This real-world example illustrates how BESS containers, in conjunction with solar power, can overcome the challenges of off-grid cold chain logistics, bringing reliable and sustainable refrigeration solutions to remote areas.

Low-Carbon Transformation and EU Compliance

The EU’s ambitious goal of achieving net-zero emissions by 2050 has cast a spotlight on the cold chain industry, compelling companies to adopt sustainable practices. BESS (Battery Energy Storage System) containers emerge not only as a paragon of energy efficiency but also as a strategic compliance asset, enabling cold chain enterprises to navigate the regulatory landscape while reducing their environmental impact.

Reducing the Cold Chain’s Carbon Footprint

The cold chain’s carbon footprint is predominantly shaped by its reliance on fossil fuel-generated grid power. Refrigeration systems, which operate continuously to maintain optimal temperatures for perishable goods, consume substantial amounts of electricity, much of which is sourced from non-renewable energy sources. BESS containers offer a transformative solution by integrating renewable energy sources such as solar and wind power into the cold chain’s energy ecosystem.

These innovative storage units function as a reservoir for excess renewable energy, capturing and storing power generated during periods of high production, such as midday when solar panels are most productive. This stored energy is then deployed during peak demand hours or when renewable energy generation is low, ensuring a consistent and sustainable power supply. By reducing dependence on coal and gas-fired electricity, BESS containers can significantly slash emissions, with studies indicating a potential reduction of 20–30% per facility[7].

Real-World Win: French Food Logistics Company

The efficacy of BESS containers in decarbonizing the cold chain is exemplified by the experience of a leading French food logistics company, which serves major supermarket chains, including Carrefour. In 2022, the company embarked on a sustainability initiative, installing BESS containers in ten of its warehouses. The results, achieved within a single year, are nothing short of remarkable:

| Metric | Pre-BESS | Post-BESS |

|---|---|---|

| Carbon Footprint | Baseline | 28% reduction(equivalent to removing 4,500 cars from the road) |

| Renewable Energy Integration | 5% | 40% of warehouse energy sourced from on-site solar |

| Brand Value | – | Awarded “Sustainable Supplier” certificationSecured contracts worth €12 million |

This successful implementation not only underscored the environmental benefits of BESS containers but also delivered substantial business advantages, enhancing the company’s reputation and competitiveness in the market.

Meeting EU Sustainability Regulations

The EU’s regulatory framework, designed to accelerate the transition to a low-carbon economy, includes stringent measures such as the Carbon Border Adjustment Mechanism (CBAM) and the Sustainable Finance Disclosure Regulation (SFDR). These regulations impose penalties on high-emission operations and incentivize companies to adopt sustainable practices. BESS containers play a crucial role in helping cold chain companies comply with these regulations:

- CBAM: By reducing the embedded carbon in imported and exported perishable goods, BESS containers enable companies to avoid tariffs imposed by the CBAM, safeguarding their profit margins and market access.

- SFDR: The transparency and data-driven insights provided by BESS containers facilitate accurate reporting of energy efficiency gains, which is essential for attracting environmentally conscious investors and accessing sustainable finance.

As succinctly put by an EU cold chain CEO, “Investing in BESS containers is not merely an investment in energy; it’s an investment in regulatory compliance, financial resilience, and the long-term viability of our business.” This perspective encapsulates the dual benefits of BESS containers, which serve as both a sustainability solution and a strategic business asset in the evolving landscape of European cold chain logistics.

Conclusion: The Future of BESS in European Cold Chain

BESS containers have transcended the realm of mere “nice-to-haves” and firmly established themselves as essential assets for the European cold chain. Let’s delve deeper into the multi-faceted value they bring to the table:

- Cost savings: Through strategic peak shaving, BESS containers can slash energy bills by an impressive 20–35%. By intelligently managing electricity consumption during periods of high demand, businesses can avoid costly peak-rate charges and optimize their operational budgets.

- Reliability: In an industry where even a brief power outage can result in catastrophic losses, BESS containers act as a crucial safeguard. By providing backup power, they prevent millions of euros’ worth of cargo from spoiling during outages, ensuring the integrity of the cold chain and protecting businesses from significant financial setbacks.

- Sustainability: BESS containers play a pivotal role in the European cold chain’s journey towards sustainability. By reducing emissions by 20–30% and facilitating the integration of renewable energy sources, they help businesses meet their environmental goals and contribute to a greener future.

- Compliance: With the EU’s ambitious net-zero targets looming large, compliance is no longer optional—it’s a necessity. BESS containers enable companies to align their operations with these goals, ensuring they remain competitive in an increasingly environmentally conscious market.

The numbers speak for themselves: Industry forecasts project a staggering 40% annual growth in BESS adoption within the European cold chain through 2030 [8]. As the demand for perishable goods continues to surge and energy costs remain stubbornly high, this growth trajectory is only expected to accelerate, solidifying BESS containers’ status as a game-changer in the industry.