The Energy Hangover Plaguing European Breweries

Let’s cut to the suds: Brewing great beer is thirsty work—for electricity. The numbers don’t lie:

Energy Consumption Breakdown

The average liter of beer consumes a staggering 2–4 kWh of energy. To truly grasp the scale, here’s a detailed breakdown of energy usage across each brewing stage:

| Brewing Stage | Energy Consumption (%) | Key Activities |

|---|---|---|

| Mashing | 35–40% | Heating water to dissolve grains |

| Boiling | 25–30% | Maintaining high temperatures |

| Fermentation | 15–20% | Cooling and temperature control |

| Packaging | 10–15% | Bottling, canning, and labeling |

Notably, mashing and boiling alone account for a significant 60% of total energy consumption. This makes these stages prime candidates for efficiency enhancements.

Financial Impact on SMBs

For small and medium-sized breweries (SMBs), energy bills aren’t just line items—they’re financial burdens. On average, these breweries allocate 15–20% of their annual revenue to energy costs. Consider these eye-opening real-world examples:

- Case Study: A medium-sized brewery with an annual revenue of €500,000 spends €75,000–€100,000 on energy each year.

- Alternative Uses for Funds: This substantial amount could instead be allocated towards:

-

- Purchasing 20–25 tons of premium specialty hops

-

- Installing state-of-the-art cooling systems in a new taproom

-

- Funding marketing campaigns to expand brand reach

Adding to the challenge, the EU’s Circular Economy Action Plan mandates a non-negotiable target: a 40% emissions cut by 2030. For microbreweries relying on local taproom sales, meeting this goal feels like brewing a barrel-aged stout with a home coffee maker—technically possible, but financially and logistically daunting.

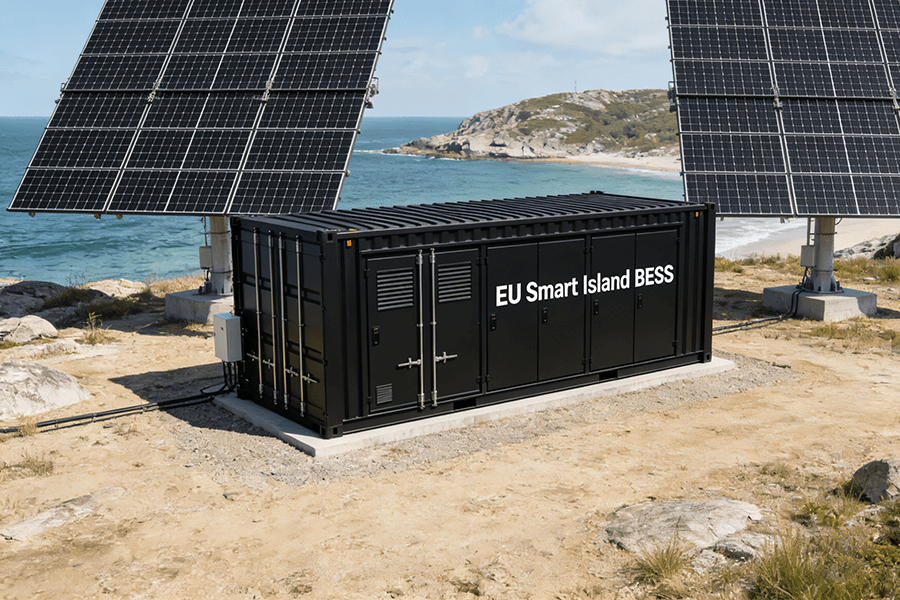

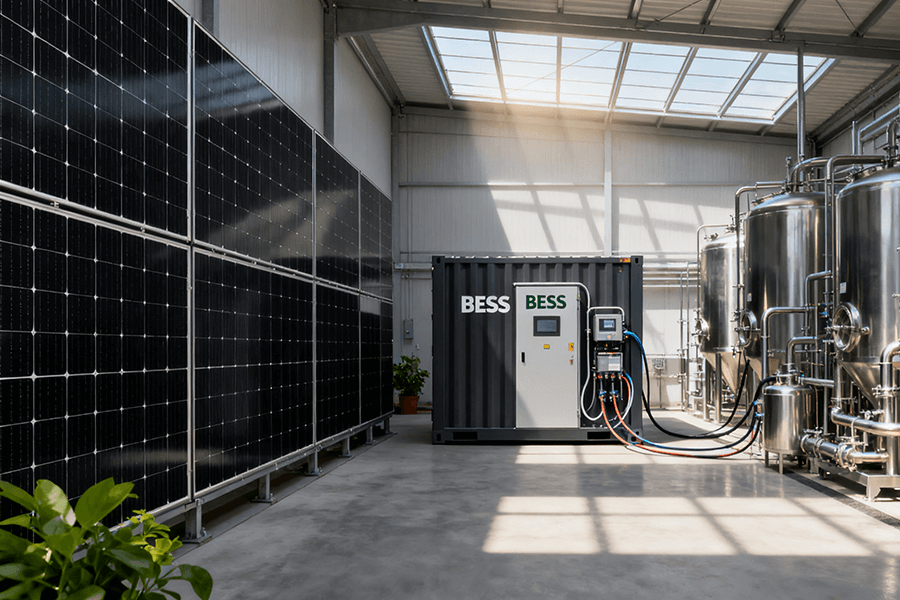

Enter BESS Containers

Compact, portable, and budget-friendly, BESS containers are the solution breweries need. Think of them as your brewery’s “energy bodyguard,” shielding profits from peak demand charges, power outages, and green regulation fines. The best part? No advanced engineering degree required—just straightforward, plug-and-play relief for your biggest operational challenges.

These Battery Energy Storage Systems (BESS) operate by storing excess energy during off-peak hours when electricity rates are lower. Breweries can then utilize this stored energy during peak demand periods, avoiding costly surcharges and reducing overall energy costs. Additionally, BESS containers serve as a reliable backup power source during outages, ensuring critical brewing processes remain uninterrupted.

Core Benefits: BESS Containers as Your Brewery’s Silent Partner

BESS containers aren’t just for tech nerds in lab coats. They’re purpose-built to solve the exact pain points that keep brewers up at night—like watching a €10,000 batch turn to swill during a thunderstorm blackout. Let’s break down the tangible benefits, illustrated with real-world brewery success stories that showcase the transformative power of BESS technology:

Peak Shaving: Slash Those “Ouch” Electricity Bills

Here’s the grid’s dirty secret: When everyone’s using power simultaneously (read: when you’re boiling wort during peak brewing hours), utility companies hike rates significantly. These “peak demand charges” can constitute 30–40% of your monthly electricity bill, eating into your bottom line. BESS containers outsmart this system through a two-step approach:

- Energy Storage: BESS units store cheap electricity during off-peak hours, typically between 2–6 AM, when rates can drop by 50–70%. This is when the grid has excess capacity and lower demand, translating to substantial savings.

- Strategic Discharge: The stored power is then discharged during the busiest brewing times, such as 10 AM–4 PM, when energy-intensive processes like mashing and boiling are in full swing. By using stored energy instead of drawing from the grid at peak rates, breweries can achieve significant cost savings.

Real Win: Belgian Craft Brewery (Ghent, 2024)

A family-run brewery in Ghent took a proactive approach to managing its energy costs by installing a 500kWh BESS container. The results were nothing short of remarkable:

| Metric | Before BESS | After BESS | Reduction |

|---|---|---|---|

| Peak Energy Usage (kW) | 1,200 | 720 | 40% |

| Annual Electricity Savings | – | €45,000 | – |

| Additional Production Capacity | – | 9,000 liters | – |

This annual saving of €45,000 is equivalent to the production cost of 9,000 extra liters of their flagship IPA (at a production cost of €5/liter). Pro tip: That’s 4,500 free pints (at €10/pint) for your taproom—an excellent opportunity to boost customer loyalty and footfall.

Backup Power: Save Your Batch (and Your Sanity)

Brewing is a finicky process that demands precise temperature control around the clock: ±1°C for fermentation and ±0.5°C for cooling. Even a single hour of power loss can have catastrophic consequences:

- Batch Ruination: Spoil a batch worth €10,000+, such as a 5,000-liter lager batch.

- Operational Disruptions: Force you to discard spoiled beer, delay deliveries, and damage your reputation with customers.

Traditional generators have their drawbacks—they take 5–10 minutes to start up and are notoriously noisy, which can disrupt the ambiance of your taproom. In contrast, BESS containers offer an instant solution:

- Immediate Response: BESS units kick in instantly, ensuring seamless operation without any downtime.

- Silent and Hassle-Free: Unlike generators, BESS containers require no fuel handling, making them a clean and convenient backup power source.

Real Win: German Bavarian Brewery (Munich, 2024)

A Munich-based brewery installed a 300kWh BESS container to safeguard its operations against power outages. During a 2-hour grid outage caused by a severe storm, the BESS system proved its worth:

| Metric | Before BESS | After BESS | Reduction |

|---|---|---|---|

| Peak Energy Usage (kW) | 1,200 | 720 | 40% |

| Annual Electricity Savings | – | €45,000 | – |

| Additional Production Capacity | – | 9,000 liters | – |

Fun fact: 5,000 liters of beer equates to 6,666 standard 750ml bottles—enough to supply a village of 1,000 people for a week. With BESS containers, your bottom line and your batches are in safe hands.

Sustainability: Brew Green, Sell More (It’s That Simple)

European beer drinkers aren’t just buying a pint—they’re buying a values statement. In an era where sustainability is no longer a niche concern but a mainstream expectation, consumer behavior has undergone a significant shift. A 2025 survey by the European Craft Beer Association (ECBA) unearthed compelling data that underscores the importance of environmental stewardship in the beer industry:

- 72% of craft beer buyers actively seek out brands with tangible green credentials. Whether it’s breweries harnessing solar power or achieving carbon neutrality, these visible eco-initiatives act as powerful differentiators in a crowded marketplace.

- 45% of consumers are not only environmentally conscious but also willing to put their money where their values are, opting to pay a premium of 10–15% for “eco-beer”.

This presents a golden opportunity for breweries, big and small. However, the path to sustainability often seems fraught with financial hurdles, especially for small and medium-sized businesses (SMBs) operating on tight budgets. Enter Battery Energy Storage System (BESS) containers—a game-changing solution that makes sustainability not just an aspiration but an achievable reality. Here’s how:

Renewable Energy on a Budget (No Grid Upgrades Required)

Rooftop solar panels have long been hailed as a cornerstone of renewable energy adoption. They harness the sun’s abundant energy, reducing reliance on fossil fuels and cutting carbon emissions. However, the sun doesn’t shine 24/7. When the sun sets and the brewing process is still in full swing, breweries without energy storage capabilities face a significant challenge. Without a way to store excess solar energy generated during the day, an astonishing 40–50% of the solar power produced is wasted, sent back to the grid for a meager return.

BESS containers provide an elegant solution to this problem. These self-contained units are designed to store excess solar energy, ensuring that breweries can continue to draw on clean, renewable power long after the sun has set. The beauty of BESS containers lies in their simplicity and cost-effectiveness:

- No need for expensive grid upgrades

- No red tape to navigate

- No need to plead with utility companies for permission

It’s a plug-and-play solution that makes renewable energy accessible to breweries of all sizes.

Solar + BESS Impact: Spanish Craft Brewery (Barcelona, 2024)

The transformative power of combining solar panels with BESS containers is best illustrated by the experience of a Spanish craft brewery in Barcelona. Before integrating a 200kWh BESS container, the brewery was already utilizing a 100kW solar system. However, they were only able to utilize 55% of the solar energy generated, with a staggering 45% being wasted and sent back to the grid.

After installing the BESS container, the brewery witnessed a remarkable turnaround:

| Metric | Before BESS (100kW Solar) | After 200kWh BESS | Improvement |

|---|---|---|---|

| Solar Energy Utilization | 55% (45% wasted to grid) | 90% (10% wasted) | +35% |

| Annual Carbon Emissions | 200 tons | 120 tons | -80 tons (-40%) |

| Monthly Electricity Bill | €8,200 | €5,330 | -35% (€2,870 saved/month) |

The impact of these changes extends far beyond the brewery’s bottom line. Cutting 80 tons of CO₂ emissions is equivalent to:

- Planting 2,222 trees

- Taking 17 cars off the road for a year

It’s a significant contribution to the fight against climate change, and it’s all made possible by the smart integration of BESS containers.

Bag the EU Ecolabel (and Watch Sales Boomerang)

In the European market, the EU Ecolabel is the gold standard for green products. It’s not just a label; it’s a “trust badge” that instantly signals to eco-conscious shoppers that a product meets the highest environmental standards. For breweries looking to differentiate themselves in a competitive market, obtaining the EU Ecolabel is a strategic move.

To qualify for the EU Ecolabel for beer, breweries must meet stringent criteria:

- Reduce carbon emissions by at least 15% compared to industry averages.

- Source 50% or more of their production energy from renewable sources.

- Implement measures to reduce water usage by 10%.

Meeting these requirements might seem daunting, but BESS containers offer a practical pathway to compliance. These systems help breweries optimize their energy usage, increase their reliance on renewable energy, and reduce their carbon footprint—all without the need for a costly and disruptive overhaul of their existing operations.

Real Win: Czech Brewery (Prague, 2024)

A Czech brewery in Prague serves as a shining example of the benefits of obtaining the EU Ecolabel with the help of BESS containers. By integrating a 400kWh BESS container into their operations, the brewery was able to:

- Cut emissions by 22%, far surpassing the EU Ecolabel’s 15% requirement.

- Increase renewable energy usage from 40% to 65%, demonstrating a significant commitment to sustainability.

- Boost sales by 15% in just 6 months, fueled by effective Ecolabel marketing and partnerships with eco-focused bars.

But the benefits didn’t stop there. The EU Ecolabel also opened doors to valuable EU grants. In this case, the brewery was awarded €15,000 to expand their taproom, further enhancing their business and solidifying their position as a leader in sustainable brewing.

Budget-Friendly Solutions: BESS for Cash-Strapped Breweries

Let’s be real: SMBs don’t have €100k lying around for energy storage. Capital-intensive investments in battery energy storage systems (BESS) can strain the financial resources of small and medium-sized enterprises, especially in the competitive brewing industry. That’s why forward-thinking BESS providers are revolutionizing the market with flexible models designed to align with your budget—no over-investment, no buyer’s remorse.

Leasing & Shared BESS: Split the Cost, Keep the Savings

Why commit to purchasing a BESS when you can opt for a more agile and cost-effective solution? Leasing or sharing a BESS with neighboring breweries presents a game-changing approach, akin to carpooling but for energy storage. This collaborative model can slash costs by an impressive 50–60%, making advanced energy management accessible to businesses of all sizes.

Real Win: 5 Italian Craft Breweries (Tuscany, 2024)

In a pioneering initiative, five craft breweries in Tuscany joined forces to lease a 1.5MWh shared BESS container, strategically installed at a central warehouse. The results of this innovative partnership speak volumes:

- Cost Efficiency: By pooling resources, each brewery reduced its monthly expenditure on energy storage to €2,000, a significant drop from the €5,000 they would have paid for a standalone 300kWh system.

- Annual Savings: Each participating brewery enjoyed total annual savings of €36,000, a substantial boost to their bottom line.

- Shared Maintenance: Say goodbye to the headache of hiring and managing expensive technicians. With a shared BESS, a single specialized team handles all maintenance needs, streamlining operations and reducing complexity.

- Value-Added Initiatives: Leveraging their newfound savings, the breweries launched a joint “Eco-Beer Tour,” attracting eco-conscious tourists to their taprooms and enhancing their brand image as sustainable businesses.

Modular Scaling: Grow as You Brew More

BESS containers offer a distinct advantage with their modular design, allowing breweries to start small and scale up seamlessly as their production demands evolve. Begin with a 200kWh unit and add more as needed, embracing a “pay-as-you-grow” model for energy storage that eliminates the risk of overspending on unused capacity.

Scalability Showdown: Containerized vs. Traditional BESS

| Metric | Traditional BESS | Containerized BESS | Advantage |

|---|---|---|---|

| Initial Cost (300kWh) | €85,000 | €60,000 | €25,000 savings 💰 |

| Expansion Time (add 500kWh) | 6–12 months | <72 hours | 200% faster ⚡ |

| Cost per Added MWh | $210,000 | $145,000 | 31% cheaper |

| Downtime During Upgrade | 1–2 weeks (production stops) | 0 hours (install during off-hours) | Keep brewing! 🚀 |

Real Win: Swedish Microbrewery (Stockholm, 2024)

A Swedish microbrewery in Stockholm serves as a prime example of the benefits of modular BESS scaling. As the brewery doubled its output from 50,000 to 100,000 liters per year, it expanded its BESS from 300kWh to 800kWh with remarkable efficiency:

- Cost Avoidance: By opting for a modular containerized BESS, the brewery avoided a €40,000 over-investment that would have been necessary with a traditional, fixed-capacity system.

- Uninterrupted Production: The upgrade process was completed over a weekend, ensuring zero downtime and uninterrupted brewing operations. This seamless transition minimized disruption to production schedules and customer deliveries.

Why Maxbo Solar’s BESS Containers Are a Brewery’s Best Friend

At Maxbo Solar (www.maxbo-solar.com), we don’t just sell BESS containers—we engineer comprehensive solutions tailored specifically for the unique demands of brewers. With over five years of dedicated research and development, we’ve refined our energy storage systems to address the trifecta of challenges faced by small and medium-sized breweries: stringent budget constraints, limited physical space, and zero tolerance for operational downtime. Here’s what sets us apart from the competition:

Our Secret Sauce: Brewery-Tailored Design

One-size-fits-all solutions simply won’t cut it in the nuanced world of brewing. Our BESS containers are meticulously crafted with the distinct needs of breweries in mind, ensuring seamless integration and optimal performance:

- Plug-and-Play Installation: Our advanced modular design allows for rapid deployment within 72 hours or less, even during active fermentation cycles. Our installation teams work in harmony with your production schedule, minimizing disruption and ensuring continuous operation.

- UL 9540A Certified: Safety is our top priority. Our containers meet the rigorous standards of UL 9540A certification, making them suitable for both indoor and outdoor use. Whether you’re working with a compact brewery yard or looking for an indoor installation, our systems comply with all EU safety regulations, providing you with peace of mind.

- Weather-Resistant Engineering: Built to withstand the diverse European climate, our containers are equipped with state-of-the-art thermal management systems. They are freeze-proof for harsh winters and feature efficient heat dissipation mechanisms for scorching summers, safeguarding your energy storage from the elements and preventing weather-related disruptions.

Flexible Contracts That Fit Your Cash Flow

We understand that the financial landscape for SMBs is dynamic, and flexibility is key. That’s why we offer a range of contract options designed to align with your brewery’s unique financial situation:

| Contract Type | Details | Benefits |

|---|---|---|

| Leasing | Start at just €1,800 per month for a 300kWh container. No upfront capital investment required. | Preserve your capital for other critical business needs. Enjoy predictable monthly payments. |

| BESS-as-a-Service (BESSaaS) | Pay per kWh of energy used, similar to a streaming service model. | Ideal for seasonal breweries with fluctuating energy demands. Only pay for what you consume. |

| Group Discounts | Partner with neighboring breweries to share a BESS system and enjoy a 25% discount on the total cost. | Cost-effective solution for multiple breweries. Leverage economies of scale. |

Real Results for Real Breweries

The proof of our solution’s effectiveness lies in the success stories of our clients. Take, for example, a mid-sized brewery in Lisbon, Portugal, which installed three of our 300kWh containers in 2024:

- Cost Savings: Reduced peak demand charges by an impressive 42%, translating to monthly savings of €18,700.

- Sustainability Gains: Boosted solar energy utilization from 52% to 88%, resulting in an annual reduction of 75 tons of greenhouse gas emissions.

- Operational Resilience: Avoided two batch losses during grid outages, saving a total of €22,000 in potential revenue.

As the brewery’s manager put it, “Maxbo didn’t just sell us a battery—they helped us keep brewing, even when the grid failed. Their solution has been a game-changer for our business.”

We Speak Your Language

Technical jargon has no place in our conversations. Instead of discussing “lithium-ion cathodes” and “power conversion efficiency,” we talk about what matters most to you: mashing cycles, cooling loads, and compliance with EU Ecolabel deadlines. Our team comprises former brewers who intimately understand the intricacies of the brewing process and the associated energy challenges.

Ready to take the next step towards more efficient, sustainable, and cost-effective brewing? Visit www.maxbo-solar.com or reach out to us at [email protected]. As a bonus, we’re offering a free energy audit for your brewery, tailored to identify the best BESS solution for your specific needs.

Conclusion: Cheers to BESS—The Brewery Game-Changer

For European brewery SMBs, BESS containers aren’t a luxury—they’re a lifeline. They:

- Slash energy costs by 30–45% (freeing up cash for hops, marketing, or taproom upgrades).

- Protect batches from power outages (no more dumping €10k+ of beer).

- Unlock green certifications (EU Ecolabel) and higher sales (72% of drinkers want eco-beer).

With flexible financing (leasing, shared systems) and modular scaling, there’s no excuse to wait. The EU’s 2030 emissions deadline is just 5 years away—now’s the time to act.

To industry associations: Let’s make BESS mainstream. Host workshops, negotiate group purchasing deals, and share success stories. When breweries thrive, we all raise a glass.

Here’s to cheaper, greener, more resilient beer. Prost! Santé! Cheers!