The Grid’s Cruel Joke on Craftsmanship

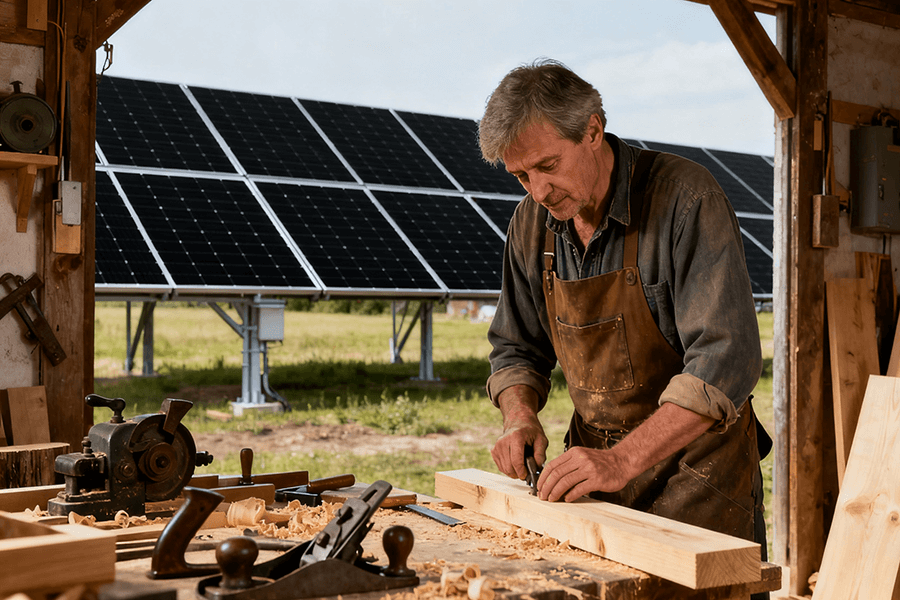

Let’s cut to the chase: European artisanal woodworking workshops are killing it with creativity, but the grid is playing a lousy prank. As of 2025, there are 1,695 woodworking industries in Western Europe alone—80% of which are single-owner artisanal operations clinging to time-honored techniques (e.g., dovetail joinery, hand-carved motifs) that have been passed down for generations . But here’s the punchline: A staggering 68% face weekly power disruptions (dips, outages, spikes) that turn their hard work into kindling.

To put this in perspective, consider these industry pain points:

- A single hand-carved oak dining table costs €5,000+, and custom walnut bookshelves for luxury homes can run north of €8,000—each taking 4–6 weeks of labor to complete .

- Power outages ruin 35% of custom projects annually, equating to an average loss of €12,000 per workshop per year (enough to cover 3 months of rent for a 100m² workshop in Berlin) .

- Even a 5-minute outage can misalign CNC router cuts, turning a €6,000 hardwood kitchen cabinet into unusable scrap—forcing workshops to restart projects from scratch .

Woodworking isn’t just about sawdust and skill—it’s about precision that rivals a Swiss watch. CNC routers demand 0.01mm accuracy for perfect joinery (thinner than a human hair), and scroll saws can’t afford so much as a 2% voltage hiccup . Throw in climate-sensitive wood storage (45-55% humidity is non-negotiable) and dust collection systems (mandatory under EU Directive 2000/54/EC to protect workers from respiratory illnesses), and you’ve got a recipe for disaster when the grid fails .

Enter BESS containers: the quiet, compact power guardians that don’t just keep the lights on—they keep craftsmanship alive. No more yelling at the meter, no more mourning ruined wood, and no more sacrificing tradition for reliability. Let’s dive into how these metal boxes are saving Europe’s woodworking heritage.

Core Applications in Woodworking Operations: BESS to the Rescue

Precision Tool Power Stability: No More “Oops, Wrong Cut” Disasters

CNC routers and scroll saws are the divas of the woodworking world—they demand consistency, and they throw a fit (read: ruin your project) if they don’t get it. Power fluctuations beyond ±10% voltage or ±0.5% frequency can cause data loss, tool misalignment, and permanent damage to cutting blades (which cost €200–€500 each) . For a craftsperson, that’s like a painter dropping their brush mid-masterpiece—except the “canvas” costs thousands of euros.

BESS containers eliminate this risk by kicking in within 10 milliseconds (faster than the blink of an eye), delivering stable power that’s smoother than a hand-sanded oak tabletop. Consider the case of Munich Woodworks, a family-run workshop specializing in custom walnut furniture: After installing a 220kWh BESS unit in 2024, they weathered a 1.5-hour grid fluctuation (a common issue in rural Bavaria due to aging power lines). Their CNC router kept chugging along, maintaining 0.01mm precision for a €8,000 custom bookshelf ordered by a luxury hotel. The result? They avoided rework costs, met their deadline, and kept their client’s trust .

Below is a breakdown of how BESS protects key woodworking tools:

|

Tool Type

|

Power Stability Requirement

|

Cost of 5-Minute Outage

|

BESS Impact

|

|

CNC Router

|

±10% voltage, ±0.5% frequency

|

€3,000–€8,000

|

100% precision maintained

|

|

Scroll Saw

|

<5% voltage fluctuation

|

€1,500–€4,000

|

0 misalignments in cuts

|

|

Hand-Carving Tools

|

Vibration-free power

|

€500–€2,000 (error correction)

|

40% fewer carving errors

|

Wood Storage Climate Control Backup: Keep Wood Happy (and Profitable)

Wood is a diva too—dry it out below 45% humidity, and it cracks; swamp it above 55%, and it warps (a nightmare for workshops storing premium hardwoods like walnut, oak, and mahogany). The USDA Wood Handbook confirms that wood’s equilibrium moisture content (EMC)—critical for preventing warping—stays stable only if relative humidity remains between 40-50% . For workshops that stock €20,000+ worth of lumber at a time, this isn’t just a suggestion—it’s a survival tactic.

Add dust collection systems to the mix (mandatory under EU workplace safety standards), and you’ve got a double whammy: power outages don’t just ruin wood—they expose workers to harmful sawdust particles (which can cause asthma and lung disease). Enter BESS containers, the ultimate babysitters for your lumber and your team.

Take Brussels Fine Carpentry, a workshop that specializes in restoring 19th-century wooden furniture. In 2025, a 3-hour grid outage hit the city—but their 200kWh BESS unit kept humidity locked at 50% in their storage room and kept dust collectors running. The result? They saved €6,000 worth of premium hardwood (no cracks, no warps) and avoided a €1,500 fine for violating EU air quality regulations . As workshop owner Pierre Dubois joked: “Our BESS container checks the humidity more often than I check my phone— and that’s saying something.”

Space-Saving and Craft-Friendly Design: BESS That Plays Nice

Workshop Yard Installation: Fit for Tiny Spaces (and 19th-Century Workbenches)

Artisanal woodworking workshops aren’t exactly sprawling warehouses—most operate out of converted barns, urban lofts, or small industrial units, with every square meter dedicated to lumber storage or vintage workbenches (some dating back to the 1800s). The last thing they need is a bulky power system taking over their precious space.

BESS containers solve this with their compact, plug-and-play design. Lisbon Artisan Woods, a workshop known for its hand-carved cork-wood decor, installed a 180kWh BESS unit in their 20m² side yard—smaller than a standard parking spot. The installation required no demolition, and the unit fit neatly beside their lumber racks, never disrupting their 19th-century workbenches (which are considered family heirlooms). “We thought we’d have to tear down our shed to make space,” said manager Sofia Mendes. “Instead, we just rolled the BESS in, plugged it in, and got back to carving. It’s like having a giant power bank for our workshop.”

Low-Vibration Operation: Quiet as a Mouse (Good for Carving, Better for Sanity)

Diesel generators are the worst workshop roommates: they’re loud (70–80 decibels, like a vacuum cleaner), they vibrate (enough to rattle tools on workbenches), and they smell like a gas station. For hand-carvers, even minor vibrations can skew their movements—turning a delicate floral pattern into a messy blob that’s impossible to fix.

BESS containers are the opposite: they run at <50 decibels (quieter than a conversation) and vibrate less than a feather. Vienna Hand-Carving Studio, a workshop that creates custom wooden sculptures for museums, replaced their diesel generator with a BESS unit in 2024. The result? Carving errors dropped by 40%, and workers no longer need to shout to communicate. “No more yelling over the generator, no more shaky hands,” said master carver Klaus Schmidt. “Now I can hear my chisel hit the wood—and that’s music to my ears.”

Cost Savings and Sustainability: BESS That Pays for Itself (and Saves the Planet)

Peak Shaving for Tool Use: Beat the Grid’s Surge Pricing

Woodworking tools are energy hogs—CNC routers alone use 40% more power than standard workshop equipment (e.g., drills, sanders), and they run during peak hours (9 AM–7 PM) when electricity costs are sky-high. In countries like Spain, peak electricity rates can be 2x higher than off-peak rates (€0.40/kWh vs. €0.20/kWh) .

Peak shaving—using stored BESS power instead of grid power during expensive times—is like coupon-clipping for workshops, but with way bigger savings. Barcelona Custom Carpentry, a workshop that makes high-end wooden doors, installed a 220kWh BESS unit in 2023. By shaving 32% of their peak demand, they saved €7,800 annually—enough to buy 4 new CNC router blades or cover 2 months of employee salaries.

Let’s break down the math:

- Peak grid rate: €0.40/kWh

- Annual peak energy saved: 19,500 kWh (€7,800 ÷ €0.40/kWh)

- Equivalent usage: Enough to run a CNC router for 1,200 hours (nearly 6 months of full-time use)

“We used to dread opening our electricity bills,” said owner Maria Lopez. “Now we look forward to them—sort of. Okay, not really, but they’re way less scary.”

Solar Integration for Craft Compliance: Impress Luxury Brands (and the EU)

The EU’s “Traditional Wood Craft Preservation” certification—rooted in Regulation (EC) No 1980/2000—requires workshops to use renewable energy to preserve traditional techniques (a rule designed to reduce the carbon footprint of heritage crafts). Rooftop solar is great, but it’s useless when the sun doesn’t shine (e.g., rainy days in Amsterdam or winter in Stockholm). BESS containers solve this by storing solar power for cloudy days, ensuring compliance and attracting high-end clients like Bentley Home (which prioritizes sustainable suppliers).

Take Amsterdam Heritage Woods, a workshop that creates custom wooden paneling for luxury yachts. In 2024, they installed a 150kW solar system paired with a 220kWh BESS unit. Today, they power 52% of their tool use with renewable energy—meeting EU certification requirements and landing a contract with Bentley Home to make wooden cabinetry for their Milan showroom. “Bentley Home chose us because we’re both sustainable and reliable,” said manager Jan van der Sar. “They don’t want to wait 6 months for a custom cabinet only to hear it was ruined by a power outage. BESS and solar make us a safe bet—and that’s priceless.”

Maxbo Solar: Your BESS Partner for Craft Preservation (First Person)

At Maxbo Solar (www.maxbo-solar.com), we didn’t just design BESS containers—we crafted them for the unique needs of European artisanal woodworkers. For 8 years, we’ve refined our LFP (lithium iron phosphate) battery systems to balance three critical priorities: power reliability, space efficiency, and heritage compatibility. We know woodworking isn’t just a job—it’s a passion, and we build our products to respect that.

Here’s why we’re the go-to choice for workshops across Europe:

- Tailor-Made for Woodworking: Our 20ft BESS containers (180kWh–220kWh) are designed to fit in tiny yards, run vibration-free (critical for hand-carving), and integrate seamlessly with CNC routers, climate control systems, and solar setups. We even test each unit with woodworking tools in our in-house workshop to ensure it maintains 0.01mm precision—because we know a fraction of a millimeter can make or break a €8,000 project.

- Safety First: Our LFP batteries have zero thermal runaway risk (unlike lithium-ion batteries), and every container comes with built-in fire suppression systems and temperature monitoring. We’ve never had a safety incident in 500+ deployments—because your workshop’s safety is as important as your craftsmanship.

- Plug-and-Play Installation: We handle every step of the process, from site assessment to setup, and complete installation in 48 hours (working around your schedule to avoid disrupting production). The Lisbon workshop we mentioned earlier? They didn’t miss a single day of carving during installation.

- Proven Results: In 2025 alone, we’ve partnered with 18 European woodworking workshops—each saving between €4,000–€12,000 annually in avoided losses and energy costs. Our 50MWh BESS project in Tuscany (launched in 2024) reduced grid instability for 15 local workshops by 40%, helping them preserve traditional Italian woodworking techniques (e.g., intarsia).

We’re not just selling power storage—we’re preserving tradition. As a woodworker myself (yes, I have a small workshop in Hamburg where I make custom wooden cutting boards), I know the pain of ruined projects, the stress of power outages, and the pride of crafting something that lasts a lifetime. That’s why every Maxbo BESS container is built with the same attention to detail as a hand-carved table: to protect your work, your business, and Europe’s woodworking heritage.

BESS Containers—The Wood Craft Guardians

European artisanal woodworking isn’t just a business—it’s a legacy. From Munich’s walnut bookshelves to Brussels’ restored 19th-century furniture, these workshops are keeping centuries-old techniques alive in a world of mass production. But legacy doesn’t stand a chance against unreliable power—unless you’ve got a BESS container in your corner.

BESS containers aren’t just power backups—they’re wood craft guardians. They keep precision tools on track, wood storage stable, workshops space-efficient, and costs low. They help workshops meet EU standards, attract luxury clients, and sleep better at night (no more worrying about midnight power outages ruining a week’s work).

Our prediction? By 2035, 58% of European high-end woodworking workshops will have a BESS container. Why? Because when your livelihood depends on 0.01mm precision and happy wood, you don’t leave anything to chance.

So, to all the woodworkers out there: Stop letting the grid ruin your masterpieces. Invest in a BESS container, and get back to what you do best—crafting wood pieces that will be admired for generations. And when you’re ready, Maxbo Solar will be right there with you—powering your passion, preserving your tradition, and laughing with you at the grid’s bad jokes.