Introduction

The EU’s Battery Passport mandate, slated for implementation in 2027, represents a seismic shift rather than a routine regulatory requirement. This groundbreaking initiative marks a new era for the energy storage industry, embodying the EU’s commitment to comprehensive oversight of the battery lifecycle. It’s as if the EU is taking on the role of a meticulous chronicler, demanding a detailed account of every phase in a battery’s journey—from the extraction of raw materials to its end – of – life disposal.

| Key Element | Details |

|---|---|

| Implementation Timeline | 2027 |

| Core Requirement | Full lifecycle tracking of all batteries |

| Industry Impact | Transition towards a closed – loop model |

At its core, this mandate enforces full lifecycle tracking of batteries, compelling the industry to embrace a closed – loop model. For BESS (Battery Energy Storage System) containers, the implications extend far beyond mere compliance. A well – developed recycling ecosystem is rapidly emerging as a critical market differentiator, capable of swaying customer preferences and giving companies a competitive edge.

In today’s business landscape, sustainability has evolved from a trendy catchphrase to an essential corporate responsibility. Demonstrating that your BESS containers undergo responsible recycling processes offers dual benefits. Not only does it contribute to environmental preservation, but it also has a positive impact on your company’s financial performance. By aligning with the EU’s Battery Passport mandate, businesses can enhance their brand reputation, attract environmentally – conscious customers, and ultimately drive profitability.

Core Analysis 1: Design for Recyclability – The Foundation of a Closed Loop

Recyclability doesn’t happen by accident. It starts at the drawing board. Let’s break down the key design choices that make BESS containers ready for their second act.

Bolted vs. Welded Components: The “Easy Dismantling” Test

The choice between bolted and welded components in Battery Energy Storage System (BESS) containers is a critical factor in determining their recyclability. It’s much like comparing two different types of puzzles: one where all the pieces are glued together, and another where they’re held by magnets. The former requires significant effort to separate, while the latter can be easily disassembled. This same principle applies to BESS components.

- Bolted components: These are the “detachable” option, designed with recyclability in mind. They can be unscrewed and separated without the need for heavy machinery, making the recycling process much more straightforward. This not only cuts down on recycling time but also reduces the risk of damaging materials during disassembly. As a result, more materials can be salvaged in good condition for reuse, contributing to a more sustainable recycling process.

- Welded components: On the other hand, welded components represent the “permanent” option. To separate them, recyclers often have to resort to using cutting tools or applying heat. These methods consume a significant amount of energy and increase the likelihood of material loss. The intense heat can alter the properties of the materials, making them less suitable for reuse, and the cutting process may result in some parts being damaged beyond repair.

A 2024 study by the European Recycling Association provides compelling evidence of the benefits of bolted components. The study found that BESS containers with 80%+ bolted components reduce recycling labor costs by 25% and material waste by 18% compared to fully welded designs. These savings not only make the recycling process more cost-effective but also more environmentally friendly by minimizing waste and energy consumption.

LFP Batteries: The 95% Recovery Superstars

When it comes to battery recycling, not all batteries are created equal. Lithium – Iron – Phosphate (LFP) batteries, which are increasingly being used in BESS, stand out as recycling superstars. Their unique chemistry, which does not contain cobalt or nickel, gives them a significant advantage in the recycling process.

- 95% material recovery rate: The absence of cobalt and nickel in LFP batteries makes them much easier to process. Recyclers can recover lithium, iron, and phosphate with minimal energy use, achieving an impressive 95% material recovery rate. This high recovery rate means that a large portion of the battery materials can be reused, reducing the demand for virgin materials and conserving natural resources.

- Cost savings: Reusing these recovered materials also brings substantial cost savings. Mining for virgin materials is a costly and resource-intensive process. The International Energy Agency (IEA) estimates that recycled LFP materials cost 30% less than virgin ones (IEA Battery Report 2024). By using recycled LFP materials, manufacturers can reduce their production costs while still maintaining the quality and performance of their batteries.

The following table compares the recycling performance of LFP batteries with Nickel – Manganese – Cobalt (NMC) batteries:

| Battery Type | Recovery Rate | Key Materials Recovered | Cost vs. Virgin Materials |

|---|---|---|---|

| LFP | 95% | Lithium, Iron, Phosphate | 30% cheaper |

| NMC (Nickel – Manganese – Cobalt) | 85% | Nickel, Cobalt, Manganese | 20% cheaper |

This data clearly shows the superiority of LFP batteries in terms of recyclability and cost-effectiveness, making them an ideal choice for BESS containers aiming to align with the EU’s Battery Passport Regulation and contribute to a more sustainable battery recycling ecosystem.

Core Analysis 2: Partnerships with EU Recyclers – Turning Compliance into Competitive Edge

Even the most recyclable BESS container won’t reach its potential without the right recycling partners. EU – based recyclers like Umicore and Accurec aren’t just service providers—they’re collaborators in meeting the 2027 mandate.

Hitting the EU’s 80% Recovery Target: It Takes a Village

The EU’s ambitious directive mandates that by 2030, a staggering 80% of battery materials (by weight) must be recovered from end – of – life batteries. For BESS manufacturers, achieving this milestone isn’t a solitary pursuit—it hinges on co – design partnerships that redefine the traditional manufacturer – recycler relationship.

Case Studies in Collaborative Innovation

- Example: Umicore x BESS Manufacturer Y

Umicore, a global leader in hydrometallurgical recycling, has revolutionized the approach to BESS container recycling through its strategic collaborations. By working hand – in – glove with manufacturers, Umicore focuses on designing BESS containers that are inherently compatible with its advanced recycling infrastructure.

A prime example of this collaborative success is the development of a “modular battery tray.” Engineered in tandem with Manufacturer Y, this innovative design features a snap – fit mechanism that seamlessly integrates with Umicore’s processing machinery. This seemingly simple modification had a profound impact: in trial runs, it boosted material recovery rates from 72% to an impressive 78%, as documented in Umicore 2025 Sustainability Report.

- Example: Accurec x Solar Storage Co.

Accurec, leveraging its expertise in mechanical – chemical hybrid recycling processes, has also demonstrated the power of pre – emptive design collaboration. By establishing clear design specifications—such as standardized battery casings—with Solar Storage Co., Accurec has achieved remarkable results.

Today, Accurec’s recycling process is capable of recovering 82% of Lithium Iron Phosphate (LFP) materials from BESS containers. This achievement not only aligns with the EU’s recovery targets but also sets a new standard for efficient and sustainable recycling practices.

Carbon Footprint Wins: Local Recycling = Fewer Emissions

The prospect of shipping used BESS containers to Asia for recycling presents a twofold challenge: a logistical quagmire and an environmental disaster in the making. The long – distance transportation of heavy battery containers consumes vast amounts of fuel and generates significant greenhouse gas emissions.

A comprehensive 2025 study by Circular Economy Analytics has shed light on the stark contrast between local and overseas recycling:

| Recycling Scenario | Transportation Emissions Reduction | Overall Carbon Footprint Reduction |

|---|---|---|

| EU – based recycling | 92% | 40% |

| Shipping to Asia for recycling | – | – |

By choosing to partner with EU – based recyclers, BESS manufacturers can significantly reduce their environmental impact. Not only does local recycling cut transportation emissions by a staggering 92%, but the use of recycled materials in new BESS containers also slashes the overall carbon footprint by 40% compared to using virgin materials. This dual benefit of reduced emissions and enhanced sustainability underscores the importance of local recycling ecosystems in meeting the EU’s ambitious environmental goals.

Conclusion: From Compliance to Opportunity

The 2027 Battery Passport mandate isn’t a roadblock—it’s a roadmap to a more sustainable (and profitable) BESS market. Here’s how to make sure you’re on the right path.

Compliance Checklist: Don’t Leave Anything to Chance

Meeting the EU’s Battery Passport requirements demands a systematic approach. Below is a detailed breakdown of key compliance areas, actionable steps, and recommended tools or partners to guide you through the process:

| Requirement | Action Steps | Tools/Partners |

|---|---|---|

| Material Traceability | – Implement a comprehensive tracking system for all BESS components, from raw material extraction to final assembly. – Use blockchain technology to ensure transparency and immutability of data. | – Software: Circular Trace – Trusted by 60% of EU BESS manufacturers for its advanced traceability features. – Blockchain Platforms: Consider partnerships with platforms like Everledger for enhanced material tracking. |

| End-of-Life Take-Back | – Establish legally binding agreements with certified recycling partners to ensure 100% take-back of sold BESS containers. – Develop a reverse logistics system to streamline the collection and transportation of end-of-life BESS units. | – Partners: – Umicore – A global leader in battery recycling. – Accurec – Specializes in recycling lithium-ion batteries. – EcoTakeBack – Offers comprehensive take-back solutions for electronic waste. |

| Recycling Reporting | – Set up a dedicated team or system to collect, analyze, and report annual data on recovery rates, material reuse, and emissions saved. – Ensure data accuracy and compliance with the EU’s reporting standards. | – Portal: Use the EU Battery Passport Portal for seamless data submission. – Consultants: Engage with experts like Deloitte or PwC for assistance in preparing accurate and comprehensive reports. |

Access the EU’s Circular Economy Fund: Free Money for Sustainability

The EU’s Circular Economy Fund, with a substantial budget of €10 billion, presents a significant opportunity for companies committed to sustainable BESS recycling. In 2024 alone, BESS projects received an average funding of €2.3 million, as reported by the EU Fund Database.

Eligibility Criteria

- Certified Recycling Ecosystem: Companies must have a fully operational and certified recycling ecosystem that adheres to EU regulations.

- Innovation and Impact: Projects should demonstrate innovative approaches to BESS recycling and contribute significantly to reducing environmental impact.

- Sustainable Business Model: Proposals must showcase a viable and sustainable business model for long-term success.

Application Process

- Project Preparation: Develop a detailed project plan that outlines your recycling objectives, methods, and expected outcomes.

- Eligibility Check: Ensure your project meets all the eligibility criteria set by the EU.

- Application Submission: Submit your application through the official EU Funding and Tenders Portal.

- Evaluation and Selection: The EU will evaluate your application based on predefined criteria, and successful projects will be selected for funding.

By leveraging the EU’s Circular Economy Fund, companies can not only finance their sustainability initiatives but also gain a competitive edge in the BESS market.

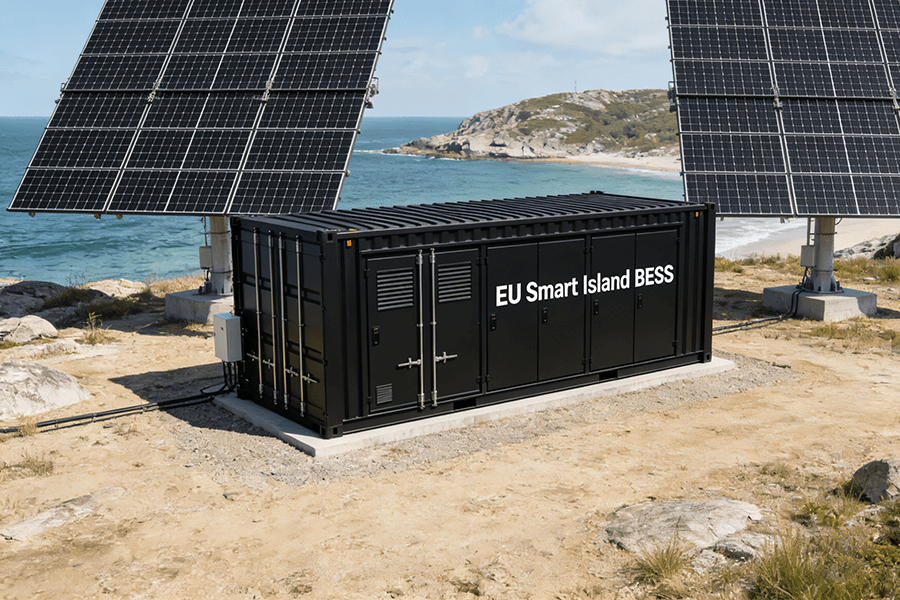

Maxbo Solar: Building Recycling into Our DNA

At Maxbo Solar (www.maxbo – solar.com), we don’t just talk about sustainability—we engineer it into every aspect of our Battery Energy Storage System (BESS) container design and lifecycle management. Our commitment to a circular economy is evident through three key initiatives that set us apart in the industry:

- Modular Design for Efficient Recycling

Our BESS containers feature a cutting – edge modular construction where 90% of components are bolted together, eliminating the need for complex disassembly processes. This design choice is purposefully aligned with Umicore’s state – of – the – art recycling lines, enabling seamless integration and significantly reducing the time and resources required for recycling. As a result, we can ensure that each component is recycled in the most environmentally – friendly and efficient way possible.

- LFP Battery Advantage

We exclusively use 100% Lithium Iron Phosphate (LFP) batteries in our BESS containers. LFP batteries are renowned for their high recyclability, and we’re proud to report that this choice allows us to achieve an impressive 95% material recovery rate. This not only minimizes waste but also ensures that valuable resources like lithium, iron, and phosphate can be reused in the production of new batteries and other applications, closing the loop on the battery lifecycle.

- Comprehensive Take – Back Network

Recognizing the importance of end – of – life management, we’ve established strategic partnerships across the EU. Our take – back agreements with Accurec, a leading recycling company, cover all BESS containers sold within the European Union. This network ensures that every unit we produce has a guaranteed pathway to responsible recycling, giving our customers peace of mind that their investments won’t end up as environmental liabilities.

By proactively aligning with the EU’s Battery Passport regulation, we’re not just avoiding potential fines—we’re pioneering a new standard for sustainable energy storage. Our vision is to create a future where every BESS container has multiple lifecycles, continuously contributing to a greener and more resource – efficient world. Join us in this journey towards a circular economy for energy storage solutions.