Introduction

The EU has set an ambitious target to transform into a “hydrogen-powered economy”. As detailed in the European Commission’s Hydrogen Strategy [1], the bloc aims to achieve 40GW of renewable hydrogen production capacity by 2030. This objective forms a crucial cornerstone of Europe’s broader initiative to decarbonize its energy sector and align with the climate targets of the Paris Agreement.

However, a significant hurdle looms large: the erratic supply of renewable energy sources, namely solar and wind power, which are the primary energy providers for green hydrogen production.

Renewable energy is as capricious as a summer tempest. In one moment, solar panels are fully exposed to sunlight, or wind turbines are operating at maximum capacity, generating an excess of electricity. In the next, clouds obscure the sun, or wind speeds decrease, causing a sharp decline in energy output. This inherent volatility disrupts the consistent power supply essential for hydrogen electrolyzers, severely hampering production efficiency.

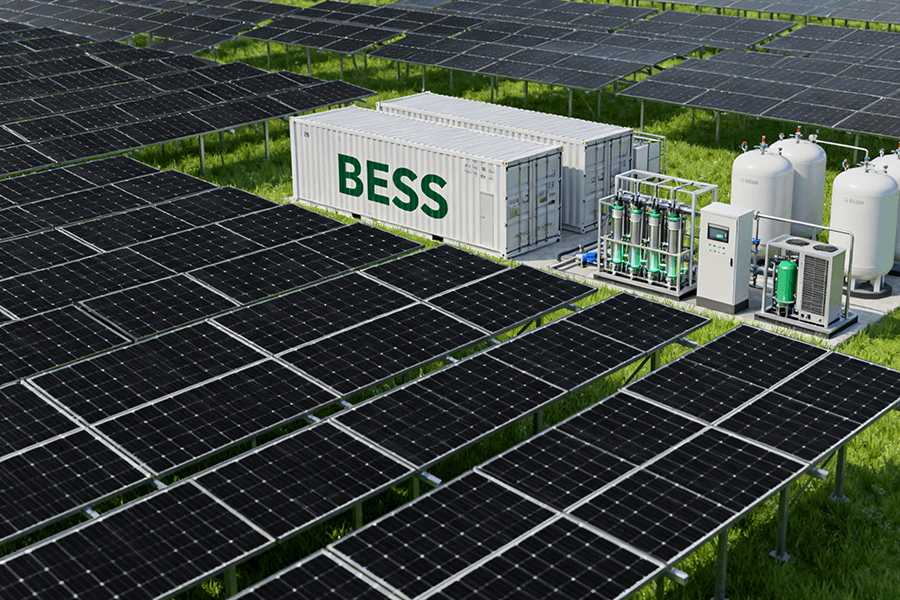

This is where BESS containers come into play. Acting as “energy stabilizers”, they mitigate these fluctuations, laying a solid and dependable foundation for Europe’s hydrogen ecosystem.

Stabilizing Renewable Energy for Green Hydrogen Production

Smoothing Power Input for Electrolyzers

Electrolyzers, the cornerstone devices in green hydrogen production, harness electricity to split water into hydrogen and oxygen. However, these advanced machines operate at their best only when supplied with a constant, uninterrupted power source. This is analogous to how high-precision industrial equipment requires a stable fuel feedstock to function optimally.

Enter Battery Energy Storage System (BESS) containers, which serve as essential “energy buffers” to address the intermittency issues typical of renewable energy sources.

How BESS Containers Stabilize Energy Flows

During peak renewable energy generation—for instance, at midday when solar irradiance reaches its zenith or during high-wind periods—BESS containers spring into action, storing excess electricity that would otherwise go to waste. On the flip side, during times of low renewable output, such as at night or when winds subside, they release stored energy. This ensures that electrolyzers can maintain continuous operation around the clock.

A Real-World Success Story from Spain

A prime example of this synergy can be found in a Spanish green hydrogen project [2]. The project combines:

- A 100MW photovoltaic (PV) plant

- A 50MW/100MWh BESS container

- A 20MW electrolyzer

Before integrating the BESS container, the electrolyzer struggled with erratic power supply fluctuations, resulting in inconsistent hydrogen production. But after implementation, the BESS container stabilized the power flow, leading to a remarkable 35% increase in hydrogen production efficiency. This improvement not only boosted output but also reduced mechanical stress on the electrolyzer, cutting down on maintenance costs and extending the equipment’s lifespan.

Avoiding Curtailment Losses

Renewable energy curtailment—the involuntary wastage of excess electricity due to insufficient storage or immediate consumption capacity—is a major challenge in Europe, both economically and environmentally. In 2020, some European regions reported curtailment rates as high as 15% [3], effectively squandering clean energy that could have been used to produce hydrogen. BESS containers provide a strategic solution by capturing surplus power and saving it for electrolyzers during periods of high demand.

Data from the International Energy Agency (IEA) highlights the effectiveness of this approach, stating that widespread BESS deployment could reduce renewable curtailment by up to 60% [3]. This significant increase in renewable energy utilization directly impacts green hydrogen production costs. According to research by BloombergNEF, every 10% rise in renewable energy utilization enabled by BESS storage corresponds to an approximate 8% reduction in green hydrogen costs [4].

Table 1: Impact of BESS Containers on Renewable Energy and Hydrogen Production

| Metric | Without BESS | With BESS | Improvement |

|---|---|---|---|

| Renewable Energy Curtailment Rate (EU Average) | 15% [3] | 6% (after 60% reduction) [3] | 9 percentage points |

| Hydrogen Production Efficiency (Spanish Project) | N/A | 35% higher [2] | 35% |

| Green Hydrogen Cost Reduction (per 10% Utilization Increase) | N/A | 8% [4] | 8% |

To better understand the financial implications, consider this hypothetical scenario: A region generates 1,000 MWh of curtailed renewable energy each year. By deploying BESS containers to capture 60% of this surplus (600 MWh), and assuming an electrolyzer efficiency of 5 kWh/kg H₂, an additional 120 metric tons of green hydrogen can be produced annually. With the current average market price for green hydrogen at around €5/kg [5], this translates to an annual revenue gain of €600,000—clearly demonstrating the economic viability of integrating BESS with electrolyzers.

Optimizing Hydrogen Storage and Utilization Processes

Peak Shaving for Hydrogen Fuel Cells

In the evolving landscape of distributed energy systems, particularly within industrial parks, hydrogen fuel cells have emerged as a promising solution for on-site electricity generation. Their operation is based on the electrochemical reaction between hydrogen and oxygen, producing electricity, heat, and water as byproducts, making them a clean and efficient energy source. However, these fuel cells face a significant challenge when dealing with sudden load spikes, such as when a factory rapidly increases its production rate. Unlike traditional power sources, hydrogen fuel cells have limited ability to adjust their output quickly, which can lead to power shortages and inefficiencies.

This is where Battery Energy Storage System (BESS) containers play a crucial role as “rapid-response backups.” Leveraging advanced lithium-ion or other high-performance battery technologies, BESS containers can store large amounts of electrical energy and release it on demand. Their operation in tandem with hydrogen fuel cells can be broken down into two key scenarios:

- Load Surge Scenario: When a sudden increase in electricity demand occurs, BESS containers can respond within milliseconds. They quickly discharge stored energy to fill the power gap, ensuring a continuous and stable electricity supply to the connected loads. This immediate response helps maintain the operational integrity of the industrial processes, preventing any disruptions due to power shortages.

- Load Drop Scenario: Conversely, during periods of low electricity demand when the hydrogen fuel cells produce more power than required, instead of wasting the excess hydrogen, the fuel cells can use the surplus energy to charge the BESS containers. This process effectively stores the excess energy for future use, optimizing the utilization of hydrogen resources and enhancing the overall energy efficiency of the system.

A real-world example from a Dutch industrial park [5] vividly illustrates the effectiveness of this synergy. In this case, the integration of a BESS container with hydrogen fuel cells led to remarkable results. The data shows that the system reduced hydrogen waste by 25%, translating into significant cost savings and a more sustainable use of hydrogen resources. Additionally, the overall energy efficiency of the industrial park improved by 18%, making the distributed hydrogen energy system more reliable and economically viable.

Grid-Connected Hydrogen-Battery Hybrid Systems

BESS containers and hydrogen storage systems can be combined to form hybrid energy storage systems that are connected to the electrical grid, offering a multitude of benefits that contribute to grid stability and improved project economics. These hybrid systems are designed to participate in grid auxiliary services, such as providing capacity reserves, frequency regulation, and voltage support.

During periods of high electricity demand or grid outages, the hybrid system can supply power to the grid, helping to maintain its stability and reliability. The complementary nature of BESS containers and hydrogen storage allows for an efficient division of labor:

- BESS Containers: With their fast response times, BESS containers are ideal for handling short-term power needs. They can quickly absorb or release energy to balance fluctuations in the grid frequency and voltage, ensuring a smooth and stable power supply.

- Hydrogen Storage: On the other hand, hydrogen storage provides long-duration backup capabilities. Hydrogen can be stored for extended periods and converted into electricity when needed, making it suitable for meeting sustained power demands during prolonged outages or peak consumption periods.

Germany has been at the forefront of implementing such hybrid systems. According to the Fraunhofer Institute for Solar Energy Systems [6], these setups have the potential to significantly boost the revenue of hydrogen projects. In fact, the report indicates that integrating BESS containers with hydrogen storage can increase project revenue by up to 30%, effectively transforming energy storage from a cost center into a profitable asset. This financial incentive not only accelerates the adoption of hydrogen and battery technologies but also paves the way for a more sustainable and resilient energy future.

Policy Support and Market Prospects in Europe

EU Policy Incentives

The EU’s comprehensive policy framework, anchored by the “Green Deal” and “Hydrogen Strategy,” serves as a cornerstone for the proliferation of hydrogen-BESS integrated projects. These initiatives are designed to accelerate the energy transition by creating a favorable regulatory and financial environment. Key policy instruments include:

- Tax Rebates: Strategic fiscal incentives play a pivotal role in reducing the financial barriers for project developers. In countries such as Germany and the Netherlands, developers can access tax rebates of up to 20% of the total project investment. This significant cost reduction not only eases the initial capital outlay but also improves the overall return on investment, making hydrogen-BESS projects more attractive to private investors.

- Priority Grid Access: To address the common bottleneck of grid connection delays, the EU grants hydrogen-BESS projects preferential treatment when integrating into the electrical grid. This streamlined process ensures that these projects can start contributing to the energy mix without undue delays, facilitating a faster deployment of sustainable energy solutions [1].

- Subsidies: The EU’s Innovation Fund, with a substantial allocation of over €9.1 billion, serves as a catalyst for the development and commercialization of low-carbon technologies. A significant portion of these funds is earmarked for hydrogen-BESS integration, supporting research, development, and demonstration projects that aim to overcome technical and economic challenges in this emerging field [1].

Market Demand Forecast

European energy research institutions project exponential growth for BESS containers within hydrogen systems, driven by a confluence of policy support, technological advancements, and decarbonization imperatives. The European Energy Research Alliance (EERA) anticipates that the market size of BESS containers for hydrogen applications will surge to 20GWh by 2030 [7]. This expansion will be concentrated in several key markets:

| Country | Market Share | Growth Drivers |

|---|---|---|

| Germany | 40% | Ambitious industrial decarbonization targets, robust manufacturing base, and extensive R&D capabilities. |

| The Netherlands | 25% | Deep expertise in energy storage technologies and strategic location of port-based hydrogen hubs. |

| Denmark | 15% | Leadership in offshore wind energy, providing an ideal foundation for synergistic BESS-hydrogen systems. |

These projections underscore the increasing importance of BESS containers in the European hydrogen ecosystem, highlighting their potential to facilitate the integration of renewable energy sources and enhance the overall resilience of the energy grid.

Conclusion

The integration of BESS containers with hydrogen systems is not just a technical fix—it’s a strategic enabler of Europe’s energy transition. By stabilizing renewable energy for hydrogen production, optimizing storage and utilization, and leveraging policy support, this synergy accelerates the shift to a low-carbon economy.

To unlock full potential, two steps are critical:

- Technological Innovation: Develop BESS containers with higher energy density and longer lifespans to reduce costs further.

- Industrial Cooperation: Foster partnerships between battery manufacturers, hydrogen producers, and grid operators to scale integrated systems.

At Maxbo Solar (www.maxbo-solar.com), we’re leading this charge. Our state-of-the-art BESS containers are engineered to seamlessly integrate with hydrogen production and utilization systems—from stabilizing electrolyzer power to supporting grid-connected hybrids. Our team of experts continuously innovates to improve efficiency and reliability, ensuring our solutions align with Europe’s hydrogen goals. Whether you’re developing a green hydrogen plant or optimizing an industrial energy system, Maxbo Solar is your trusted partner in building a sustainable energy future.