Introduction

European ports are currently grappling with an increasingly stringent regulatory environment aimed at significantly reducing maritime emissions. These regulations not only represent a global commitment to environmental sustainability but also pose substantial operational and financial challenges for port authorities and shipping companies. Three key regulatory frameworks have emerged as pivotal benchmarks for compliance, each imposing specific requirements and timelines that operators must adhere to:

- IMO 2023 Regulations: As a cornerstone of international maritime environmental policy, the International Maritime Organization (IMO) 2023 Regulations set ambitious targets for carbon intensity reduction. Specifically, these regulations mandate a 40% decrease in the carbon intensity of new ships by 2030, when compared to 2008 levels. Additionally, they emphasize the importance of utilizing shore power infrastructure whenever available, aligning with the broader objectives outlined in the IMO Greenhouse Gas Strategy. This strategy underscores the IMO’s commitment to mitigating the environmental impact of maritime transport and fostering the adoption of cleaner technologies.

- EU Fit for 55 Package: In the European Union, the Fit for 55 Package represents a comprehensive set of legislative proposals designed to achieve a 55% reduction in greenhouse gas emissions by 2030, relative to 1990 levels. A key component of this package is the requirement for all major European ports to install shore power infrastructure by 2030, specifically for vessels with a gross tonnage (GT) of over 5,000. This initiative not only aligns with the EU’s broader climate goals but also serves as a catalyst for the modernization of port facilities across the continent. For more detailed information on the EU Fit for 55 Package, please refer to the official EU webpage.

- CARB At-Berth Regulation: Although primarily applicable to ports in California, the California Air Resources Board (CARB) At-Berth Regulation has far-reaching implications for global shipping practices. This regulation targets ports handling container ships and cruise vessels, imposing strict penalties for non-compliance. Specifically, ships found in violation of the At-Berth Regulation can face fines of up to $30,000 per day per violation. These penalties serve as a powerful incentive for operators to adopt cleaner technologies and comply with environmental standards while at berth. For further details on the CARB Shore Power Rules, please visit the official CARB webpage.

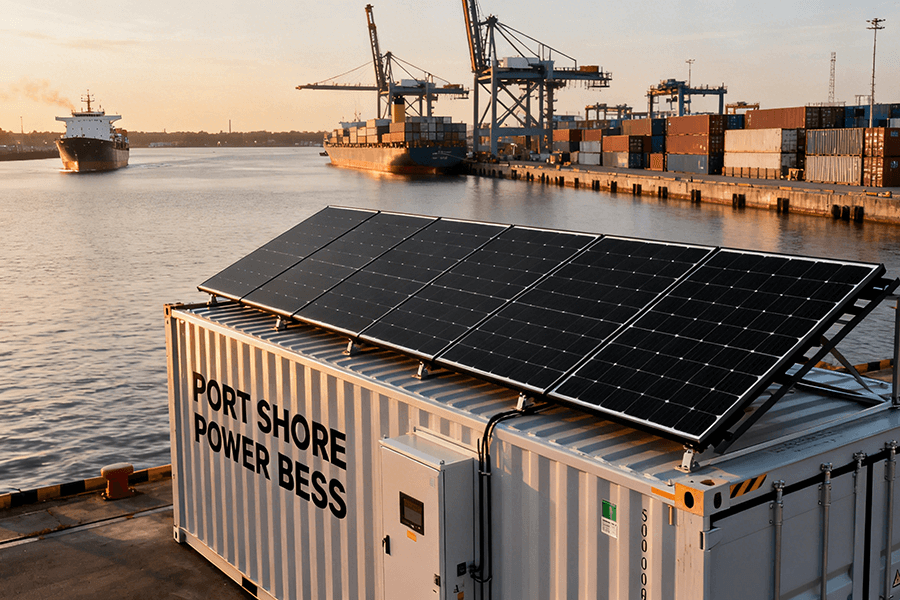

In the face of these rigorous regulatory requirements, Battery Energy Storage System (BESS) containers have emerged as a critical solution. Often referred to as the “unsung heroes” of modern port operations, BESS containers play a pivotal role in ensuring the consistent and reliable delivery of shore power, also known as “cold ironing.” By storing and distributing energy as needed, BESS containers help prevent blackouts and disruptions, enabling ports to meet their ambitious emission reduction targets without compromising on operational efficiency. This innovative technology not only addresses the immediate challenges posed by regulatory compliance but also paves the way for a more sustainable future for maritime transport.

The Significance of BESS Containers in Shore Power

BESS containers solve two critical pain points for port operators: emissions reduction and grid stability. Below is a detailed breakdown of their impact.

Reducing Emissions: From Diesel Guzzlers to Clean Power

The environmental toll of idling ships is staggering. One large container ship idling for 24 hours emits the equivalent amount of nitrogen oxides (NOₓ) and particulate matter 2.5 (PM₂.₅) as 34,000 heavy-duty trucks (source: EPA Maritime Emissions Data). These pollutants contribute significantly to smog formation, acid rain, and respiratory health issues.

BESS-supported shore power systems offer a transformative solution by replacing ship diesel generators with stored, grid-sourced energy. This shift not only curbs emissions but also adheres to stringent environmental regulations, such as the International Maritime Organization’s (IMO) 2020 Sulphur Cap.

Table 1: Emission Reductions from BESS-Enabled Shore Power in Major Ports

| Port | BESS Capacity | Emission Reduction (vs. Idling Ships) | Annual CO₂ Saved | Source |

|---|---|---|---|---|

| Los Angeles, USA | 142 MWh | 98% | 18,000+ tons | Port of Los Angeles Shore Power |

| Rotterdam, Netherlands | 68 MWh | 95% | 12,500+ tons | Port of Rotterdam Energy Transition |

| Hamburg, Germany | 50 MWh | 97% | 9,200+ tons | Hamburg Port Climate Protection |

These emission reductions have far-reaching benefits beyond environmental stewardship. A comprehensive study by the World Health Organization (WHO) revealed that port areas equipped with shore power systems experience 22% lower rates of respiratory illnesses among nearby residents (source: WHO Port Air Quality Report). This highlights the positive impact on public health and quality of life in port communities.

Alleviating Grid Surges: The 10ms Lifesaver

The electrification of ports presents its own set of challenges, particularly when it comes to grid stability. When a ship connects to shore power, it demands a sudden surge of energy—often 15–25 MW in a matter of seconds. To put this into perspective, this is equivalent to powering 18,000 homes simultaneously, which can overwhelm local grids and lead to blackouts or trigger exorbitant “demand charges” from utility providers.

BESS containers serve as a crucial “shock absorber” in this scenario, boasting an astonishing 10ms response time—significantly faster than the blink of an eye (which takes approximately 300ms). By rapidly supplying the initial energy surge, BESS systems stabilize the grid and mitigate several critical issues:

- Grid Penalties: In the EU, ports can face penalties of up to $50,000 per surge event, which can quickly accumulate and strain budgets.

- Operational Disruptions: Unstable power supply can disrupt other essential port operations, such as cranes, warehouses, and refrigeration units, leading to costly downtime and inefficiencies.

The effectiveness of BESS in grid stabilization is best illustrated by real-world examples. In 2024, the Port of Antwerp-Bruges installed a 45 MWh BESS and reported a remarkable 92% reduction in grid surge-related costs within the first six months (source: Port of Antwerp-Bruges BESS Case Study). This showcases the immediate and substantial savings that can be achieved through the strategic deployment of BESS technology.

Economic Benefits: Saving Millions While Going Green

BESS containers aren’t just eco-friendly—they’re a smart financial investment. Below are two key cost-saving mechanisms.

Cost Savings from Peak Shaving

Electricity utilities charge higher rates during “peak demand” hours (typically 8 AM–8 PM, when ports are busiest). BESS containers store energy during off-peak hours (when rates are 30–50% lower) and discharge it during peaks, a practice called “peak shaving.”

Table 2: Annual Peak Shaving Savings for European Ports

| Port Size | Average Peak Demand | BESS Capacity Needed | Annual Savings Range |

|---|---|---|---|

| Small (e.g., Le Havre) | 10–15 MW | 20–30 MWh | 500,000 |

| Medium (e.g., Barcelona) | 20–30 MW | 40–60 MWh | 800,000 |

| Large (e.g., Rotterdam) | 40–60 MW | 80–120 MWh | 1.2 million |

Deferral of Grid Upgrades: Avoiding $8M Bills

To handle growing shore power demand, ports often face mandatory grid upgrades (e.g., installing new transformers, expanding transmission lines) that cost (2–)8 million. BESS containers reduce grid stress, allowing ports to defer these upgrades by 5–10 years.

For example:

- The Port of Valencia planned a (6.2 million grid upgrade in 2023. After installing a 55 MWh BESS, it deferred the project until 2032, saving )6.2 million upfront plus inflation-related costs (Port of Valencia Energy Plan).

Implementation Challenges and Countermeasures

While BESS containers offer clear benefits, their adoption faces two key hurdles. Below are practical solutions to overcome them.

High Initial Investment: Turning Sticker Shock into Long-Term Gains

The upfront cost of implementing Battery Energy Storage System (BESS) containers in ports presents a significant barrier. A typical BESS container system for ports costs €2.0 million per 10 MWh (including installation), encompassing expenses related to battery modules, power conversion systems, cooling infrastructure, and integration. To mitigate this financial challenge, the following strategies can be effectively employed:

- Government Subsidies: Leveraging public funding initiatives can substantially reduce the financial burden. The EU’s Connecting Europe Facility (CEF) stands out as a crucial resource, offering grants that cover 30–50% of BESS costs for ports. This program not only eases the initial investment but also aligns with the EU’s broader goals of sustainable maritime development. For detailed information on eligibility and application procedures, ports can refer to the EU CEF Maritime Grants portal.

- Port-Enterprise Partnerships: Collaborative arrangements between ports and energy companies can create mutually beneficial outcomes. Ports can partner with industry giants such as Engie and Shell, which have the financial resources and technical expertise to fund BESS installation. In return, these companies receive a share of the energy savings, typically 5–10% over 10 years. This model allows ports to access necessary capital without a significant upfront outlay while providing energy companies with a new revenue stream and a foothold in the growing sustainable energy market within the maritime sector.

- Long-Term Financing: Financial institutions play a pivotal role in supporting BESS projects. Banks like the European Investment Bank (EIB) offer low-interest loans with an annual percentage rate (APR) of 2–3% specifically tailored for port BESS projects. These favorable loan terms extend the repayment period, making the investment more manageable over time. Ports interested in exploring this option can find comprehensive details on EIB Sustainable Maritime Financing.

Technical Compatibility: Solving the “Plug-and-Play” Problem

The technical landscape of shore power connections is complex, posing challenges to the seamless integration of BESS systems. Ships utilize diverse shore power connection standards; for instance, EU ships commonly adhere to IEC 61850, while U.S. ships follow IEEE 1547. This lack of standardization makes it difficult for BESS systems to function universally across different vessels. To address this issue, the following approaches have proven effective:

- Standardized Interfaces: Advancements in technology have led to the development of more versatile BESS containers. Manufacturers like Maxbo Solar now offer units with multi-protocol compatibility, supporting a wide range of standards including IEC 61850, IEEE 1547, and DNV GL. These standardized interfaces ensure that BESS containers can communicate effectively with various ship models, reducing the need for custom adaptations and enhancing interoperability.

- Pre-Installation Testing: Conducting thorough pre-installation testing is a proactive strategy to minimize compatibility issues. Ports can enlist the services of third-party labs, such as DNV GL, renowned for their expertise in maritime and energy storage systems. These labs simulate real-world scenarios, testing BESS compatibility with common ship models before deployment. The Port of Hamburg serves as a prime example, reporting a 70% reduction in compatibility issues after implementing this practice. For more insights into the testing procedures and best practices, ports can refer to the DNV GL BESS Testing resources.

WarrantyWeek’s 2025 survey found 60% of European users prefer extended warranties—as they reduce long – term risk and align with the EU’s requirement for BESS to last at least 10 years.

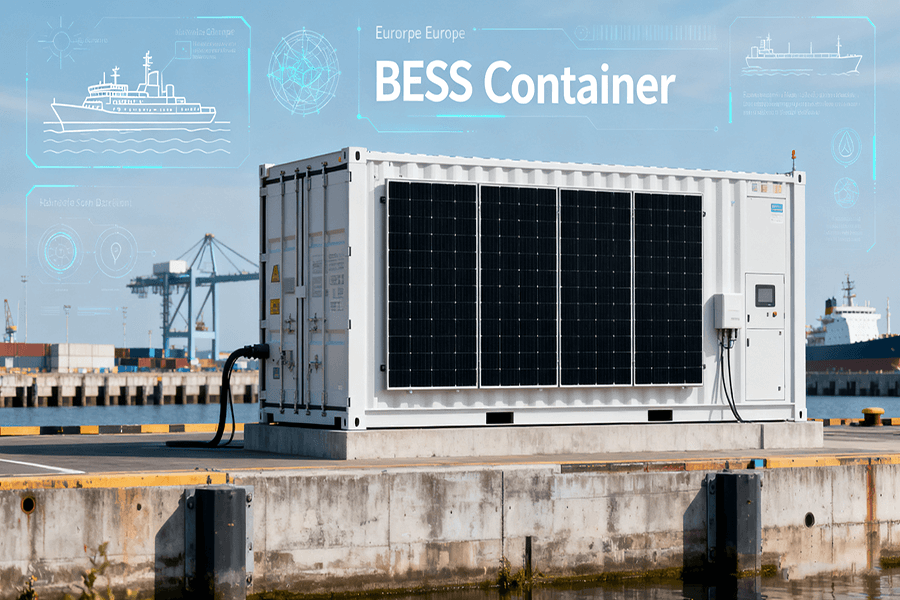

Maxbo Solar: Your Partner in Port BESS Solutions

At Maxbo Solar, we’ve spent a decade designing BESS containers specifically for the unique needs of European ports. Our systems aren’t just “off-the-shelf”—they’re tailored to:

- Withstand harsh port environments (saltwater, extreme temperatures) with IP65-rated enclosures.

- Integrate seamlessly with existing shore power infrastructure (no costly overhauls needed).

- Deliver 99.9% uptime (backed by 24/7 remote monitoring and on-site maintenance support).

Our flagship product, the MaxBESS Port Series, offers capacities from 20 MWh to 200 MWh and has been deployed in ports like Marseille (France) and Gothenburg (Sweden). For example, the Port of Marseille installed a 60 MWh MaxBESS system in 2024 and achieved:

- 98% emission reduction at berths.

- $950,000 in annual peak shaving savings.

- A 10-year deferral of a $4.8 million grid upgrade.

To learn more about how we can help your port meet regulatory targets and cut costs, visit our website: www.maxbo-solar.com.