The Energy Nightmare of Ski Teaching Bases

Picture this: A crisp Saturday morning in the Alps. Twenty kids, clad in neon gear and wobbly grins, line up for their first ski lesson. Then—*poof*—the power dies.

The magic carpet stops mid-conveyor. Snowmaking guns fall silent. The heated waiting area turns into an icebox. This isn’t a worst-case scenario—it’s a regular frustration for most European ski teaching bases.

The numbers paint a stark picture:

• Over 160 operational mountain ski teaching bases exist across Europe.

• A staggering 87% rely on diesel generators for primary or backup power [1]—a risky dependency in extreme cold.

• Power failures cost bases €10,000+ weekly in canceled lessons—direct revenue loss.

• Generator outages strand an average of 200+ beginner skiers annually[3]—damaging customer trust.

Explaining a canceled lesson to a frustrated parent? Not exactly a great way to build customer loyalty.

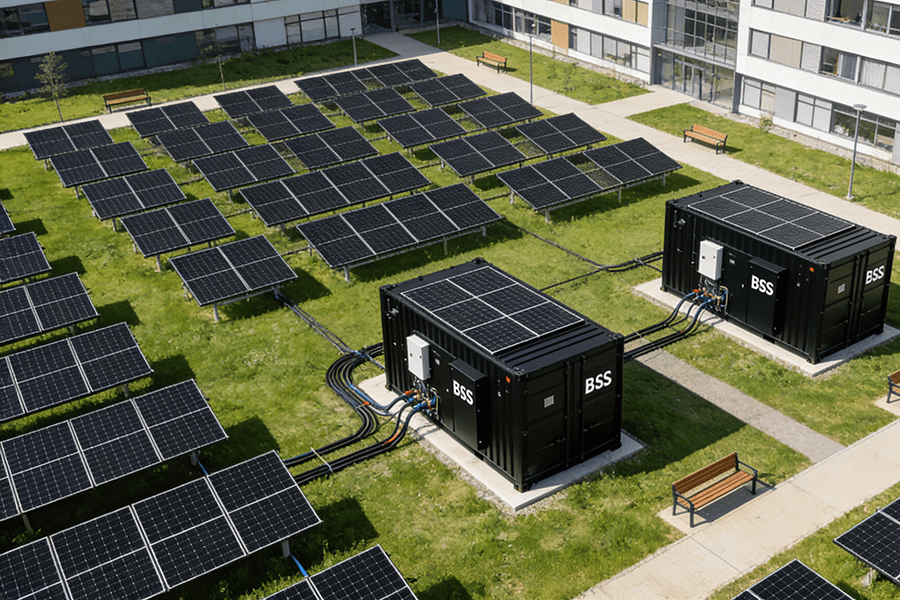

Enter BESS containers: the cold-resistant, reliable solution these safety-focused facilities need. Think of them as a “battery on steroids”—built to laugh off blizzards and keep the magic (carpets) rolling. Let’s break down how they turn energy chaos into smooth slopes.

Core Applications: BESS Keeps Lessons (and Warmth) On Track

Ski teaching bases live and die by two things: consistency and safety. BESS containers deliver both, with real-world results that make diesel generators look obsolete. Below are their most critical uses in daily operations.

Beginner Lifts & Snowmaking: The Non-Negotiable Power Pair

Magic carpets and snowmaking equipment are the backbone of any teaching base. Even a 1-hour outage halts lessons completely—you can’t teach turns if kids can’t reach the slope, and you can’t have a slope without snow.

BESS containers eliminate this risk with lightning-fast response: they kick in within 1 second of a power cut—faster than a ski instructor can yell “bend your knees!” [1].

Case Study: Austrian Kitzbühel Teaching Base

Last season, the base deployed a 350kWh BESS container. During peak hours, a grid outage hit—lasting 4 hours (enough time for most diesel generators to fail).

The BESS kept three magic carpets running and snowmaking guns active. Outcome?

• 50 lessons completed without interruption.

• €20,000 in lost revenue avoided—money kept in the business.

Instructors joked the BESS was more reliable than the local weather forecast [1].

Student Amenities & Safety: Warmth = Happy (and Safe) Skiers

For beginners, warmth isn’t a luxury—it’s motivation. A cold waiting area turns excited kids into reluctant ones. More importantly, safety systems need constant power.

Two non-negotiables here:

1. Heated waiting areas: Keep learners comfortable between runs.

2. Emergency communication: Connect instructors to rescue teams instantly.

Case Study: Swiss St. Anton Teaching Base

Last year, a brutal winter storm caused a 5-hour grid outage. The base’s 300kWh BESS container stepped up:

• Kept waiting areas heated and 150 students calm.

• Maintained emergency communication lines.

When a beginner strayed off the slope, the instructor called for help immediately. “The BESS didn’t just save money,” the base manager said. “It saved us from a disaster.”

BESS vs. Diesel: Real-World Impact Comparison

|

Scenario

|

Diesel Generator Outcome

|

BESS Container Outcome

|

Impact

|

|---|---|---|---|

|

4-hour grid outage (Kitzbühel)

|

Fails to start; operations halt

|

Runs continuously; all systems active

|

+€20,000 (avoided loss)

|

|

5-hour storm outage (St. Anton)

|

Diesel freezes; safety systems down

|

Power maintained; communication active

|

150 students kept safe

|

|

-32°C cold snap (Tromsø)

|

Complete failure; no power

|

Full capacity maintained

|

Lessons continue as scheduled

|

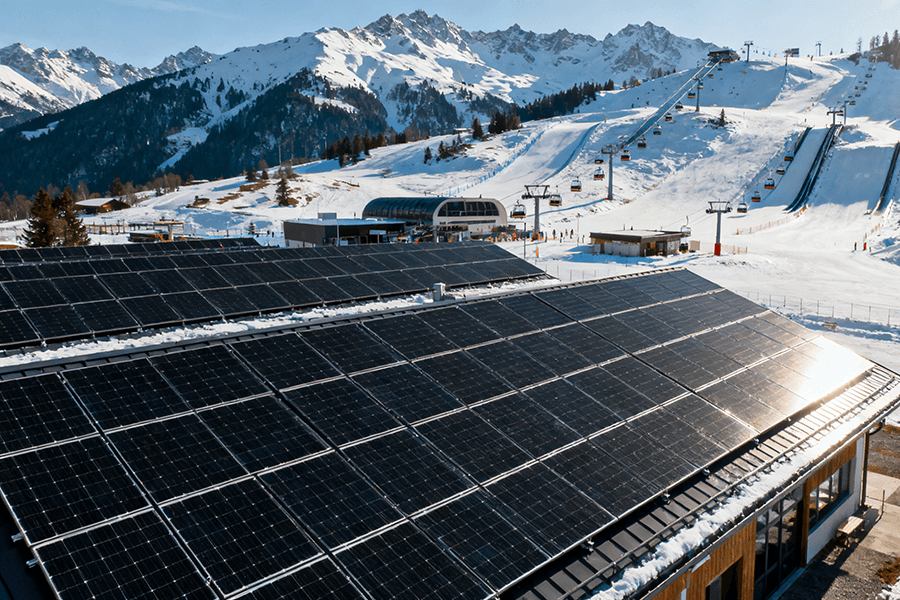

Built for the Alps: BESS’s Cold-Resistant Edge

Alpine winters are unforgiving: temperatures drop to -40°C, and snowstorms bury equipment in hours. Diesel generators crumble here—they freeze, guzzle fuel, and fail when needed most.

BESS containers? They’re engineered to thrive in these conditions.

Arctic-Grade Toughness

BESS containers for ski bases come with two winter-specific features:

1. Arctic-grade insulation: Same material used in polar research stations—locks in heat, keeps cold out.

2. Adaptive heating: Activates automatically when temps drop below -10°C—no manual intervention needed.

Case Study: Norwegian Tromsø Teaching Base

Last winter, a cold snap hit -32°C. The base’s BESS maintained full capacity, powering lessons and amenities.

The backup diesel generator? It refused to start—even after two hours of trying. The maintenance team joked it would make a better bench than a power source [1].

Ditching Diesel: Emissions & Cost Wins

Alpine regions have Europe’s strictest emission rules—diesel generators are increasingly banned or penalized. BESS eliminates diesel use entirely, which benefits both the planet and the bottom line.

Case Study: French Chamonix Teaching Base

After deploying BESS, the base achieved impressive results:

• 95% reduction in diesel consumption—drastic emission cuts.

• Earned EU “Safe Winter Sports” certification (a major draw for eco-families).

• Saved €28,000 annually in fuel costs—savings reinvested in lessons.

“We had a full-time staffer for the diesel generator,” the operations director said. “Now he teaches kids to ski. That’s a win-win.”

Sustainability & Operations: BESS = Less Hassle, More Green

Ski teaching bases need long-term viability, not quick fixes. BESS delivers on two fronts that matter most: sustainability (to attract eco-conscious customers) and operational simplicity (to cut downtime).

Solar-Wind-BESS: The Renewable Dream Team

Mountain slopes have abundant sun and wind—BESS turns that free energy into reliable power. Here’s how it works:

1. Solar panels: Installed on lift stations (no wasted space).

2. Small wind turbines: Positioned to catch alpine breezes.

3. BESS container: Stores excess energy for cloudy, calm days.

Case Study: Swedish Åre Teaching Base

The base paired a 200kW solar-wind system with a 350kWh BESS container. Now it operates 78% on renewable energy[1].

The marketing impact was immediate:

• 30% increase in bookings from eco-conscious families—new revenue stream.

“Parents used to ask about prices first,” the marketing manager said. “Now they ask about our renewable energy. BESS turned us into a destination.”

Low Maintenance: BESS vs. Diesel

Diesel generators are high-maintenance divas—they need fuel refills, oil changes, and winterization. BESS containers? They’re the laid-back alternative.

Key Maintenance Stats (per NREL BESS O&M Study 2025 [2]):

-

Diesel generators: 800 hours of maintenance per year, plus winterization costs of €3,000

-

BESS containers: 320 hours of maintenance per year, no winterization needed

-

Result: BESS reduces downtime by 80% and cuts maintenance costs by 60%

Case Study: Austrian Innsbruck Teaching Base

“With diesel, we were always fixing something—refueling at 5 a.m., troubleshooting frozen lines,” the maintenance lead said.

“With BESS, we set it and forget it. Our team now has time to take ski lessons themselves.”

Maxbo Solar BESS: Built for Ski Teaching Bases

I’ve spent 10 years in alpine renewable energy, and here’s the truth: not all BESS containers are the same. At Maxbo Solar, we don’t just build batteries—we build solutions for the unique chaos of ski teaching bases.

We know you need power when it’s -30°C, when 50 kids show up unannounced, and when the grid fails mid-storm. That’s why every Maxbo BESS is designed with your needs first.

Winter-Proof by Design

Our BESS containers beat the cold with:

• Military-grade insulation—tested in Arctic conditions.

• Adaptive heating systems (works from -40°C to 40°C).

We tested them in Tromsø’s -32°C snaps and Chamonix’s blizzards. Result? 100% uptime in extreme cold. We don’t just meet alpine standards—we set them.

Seamless Integration (No Tech Degree Needed)

Your team teaches skiing, not energy systems. That’s why Maxbo BESS is designed for simplicity:

• Integrates with existing magic carpets, snowmaking, and solar-wind setups—in hours, not days—minimal downtime.

• User-friendly touchscreen control: Check battery levels with one tap, no code required.

Hard Savings, Fast ROI

Let’s talk real numbers. Our 350kWh BESS saves bases €25,000–€30,000 annually in fuel and maintenance.

That means:

• ROI in 3–4 years (not a decade)—fast payback.

• Chamonix’s Maxbo BESS: Pays for itself in 3.2 years, with 20% more bookings from EU certification.

We don’t just sell BESS—we sell peace of mind and profit.

24/7 Support (Because Storms Don’t Wait for 9–5)

When you choose Maxbo, you’re not just a customer—you’re part of the team. We offer:

• 24/7 support: Our experts answer calls during blizzards or midnight outages—no waiting for business hours.

• On-site training: We teach your staff to use the system in 1 hour.

• Regular maintenance checks: We proactively spot issues before they cause downtime.

Last winter, St. Anton’s base had a minor glitch during a storm. Our team was on the phone in 5 minutes—guiding their maintenance manager to fix it while the BESS kept power flowing. That’s the Maxbo difference.

Ready to see what Maxbo Solar can do for your base? Visit www.maxbo-solar.com to:

• Explore our ski base case studies.

• Request a custom quote tailored to your needs.

• Chat with someone who gets the alpine energy challenge. We’re here to keep your lessons running, your students warm, and your diesel generator collecting dust.

Conclusion: The Future of Ski Teaching Bases Is Powered by BESS

BESS containers aren’t a trend—they’re the future of reliable energy for European ski teaching bases. They solve the three biggest pain points:

1. Cold weather downtime: 100% uptime in -40°C—lessons never stop.

2. Diesel costs: Save €25k–€30k annually—more profit.

3. Safety risks: Keep emergency systems and amenities running during outages—peace of mind.

Plus, they align with EU standards and attract eco-conscious families—turning operational wins into marketing wins.

Our prediction: By 2032, 85% of European ski teaching bases will replace diesel generators with BESS.

Why? Because when your business is about making skiing safe and accessible, you can’t rely on outdated technology. BESS doesn’t just power ski lessons—it powers the future of winter sports education.

To all ski teaching base managers: It’s time to say goodbye to cold fingers, stranded students, and budget-busting diesel bills. The BESS revolution is here—and it’s making your slopes safer, greener, and more profitable.

Ready to join? Maxbo Solar is right there with you—snow boots and all.