The Dark Ages of BESS O&M: Why Manual Inspection Is a Dead End

Let’s be honest: Traditional BESS O&M is like trying to fix a jet engine with a screwdriver. It’s slow, imprecise, and guaranteed to miss the small issues until they blow up into expensive disasters.

And the problem is only getting worse. With global energy storage capacity set to hit 2,000 GWh by 2025 (IEA, 2024), this “band-aid approach” of sending humans to physically check every cell is about to collapse under its own weight. The math doesn’t lie—more containers mean more man-hours, more human error, and more costs.

The Three Big Headaches of Traditional O&M

|

Pain Point

|

Real-World Impact

|

Cost Sink (Per 100 MWh BESS)

|

|---|---|---|

|

Glacial Manual Inspection

|

A team of 3-4 technicians takes 2+ days to inspect one container farm; 30% of issues go undetected, leading to cascading failures.

|

$12,000–$15,000 per inspection cycle (labor + travel)

|

|

Fault Detection: Too Little, Too Late

|

Battery cell failures are found only after outages; average downtime hits 48 hours, disrupting grid services or operations.

|

$80,000–$120,000 per outage (lost revenue + repairs)

|

|

Fixed Parameters = Wasted Energy

|

Rigid schedules ignore grid demand spikes/solar wind lulls; 12–15% of stored energy is wasted or sold at below-market rates.

|

$35,000–$45,000 in lost energy annually

|

The writing’s on the wall for outdated O&M. A 2025 industry survey found that 58% of energy storage operators cite “cost reduction” as their top tech priority(ZincFive & Data Center Frontier, 2025). And “throwing more people at the problem” isn’t the solution—it’s the problem. What’s needed is a system that works with your team, not against them.

AI to the Rescue: 3 Scenarios Where BESS Gets a Brain

AI isn’t here to replace your technicians (don’t worry, they can trade clipboards for coffee mugs and focus on high-value work). It’s here to eliminate the grunt work, spot the invisible, and turn your BESS from a passive asset into an active profit center. Here’s how it works in the real world:

Battery Health Prediction: The 3-Month Crystal Ball

Imagine knowing a battery cell is going to fail three months before it happens. That’s not magic—that’s AI crunching 10,000+ data points (temperature, voltage, charge cycles, even humidity and vibration) every second.

Traditional systems only flag issues when parameters hit “critical” levels, but AI sees the trends that precede failure. A 2025 pilot at a German 200 MWh energy storage plant proved this: AI predicted 92% of potential faults 85–95 days in advance, cutting unplanned downtime by 78% and avoiding $2.4M in outage costs (Energy Storage News, 2025).

Pro Tip: This isn’t “guesswork.” AI uses recurrent neural networks (RNNs) to spot patterns humans can’t—like a 0.02V voltage dip that signals impending cell degradation, or a 0.5°C temperature rise that precedes thermal runaway.

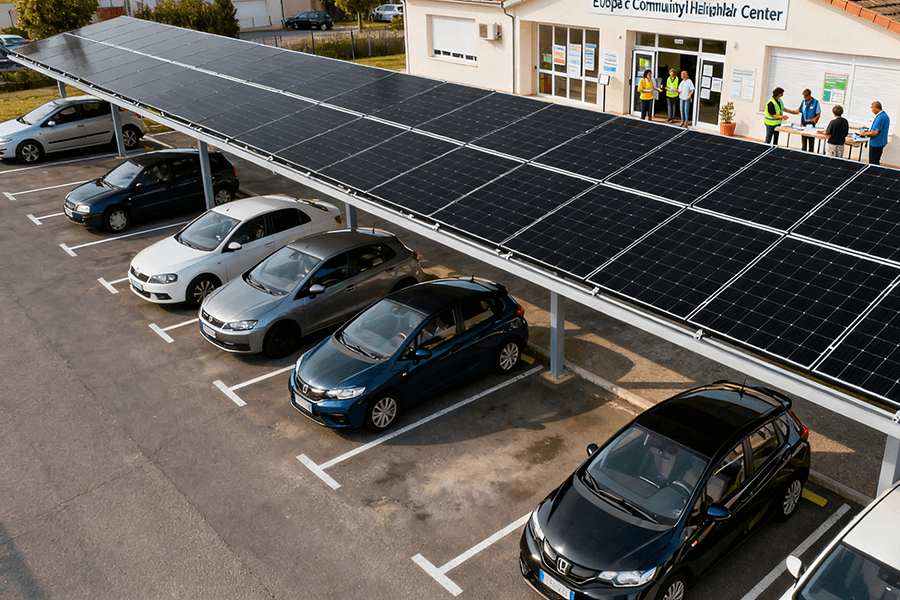

Dynamic Load Matching: BESS That Reads the Grid’s Mind

Traditional BESS runs on “set-it-and-forget-it” schedules—charging at 2 AM regardless of solar output, discharging at 6 PM even if grid demand is low. AI BESS? It’s like a DJ reading the crowd—adjusting in real time based on:

-

Grid demand fluctuations

-

Real-time solar/wind generation

-

Electricity price spikes (up to $0.50/kWh in peak hours)

-

Grid stability signals

A Dutch industrial facility using this tech cut its peak demand charges by 32% (saving €28,000 annually) and reduced energy waste to just 3%—down from 14% with traditional O&M (Maxbo Solar Case Study, 2025).

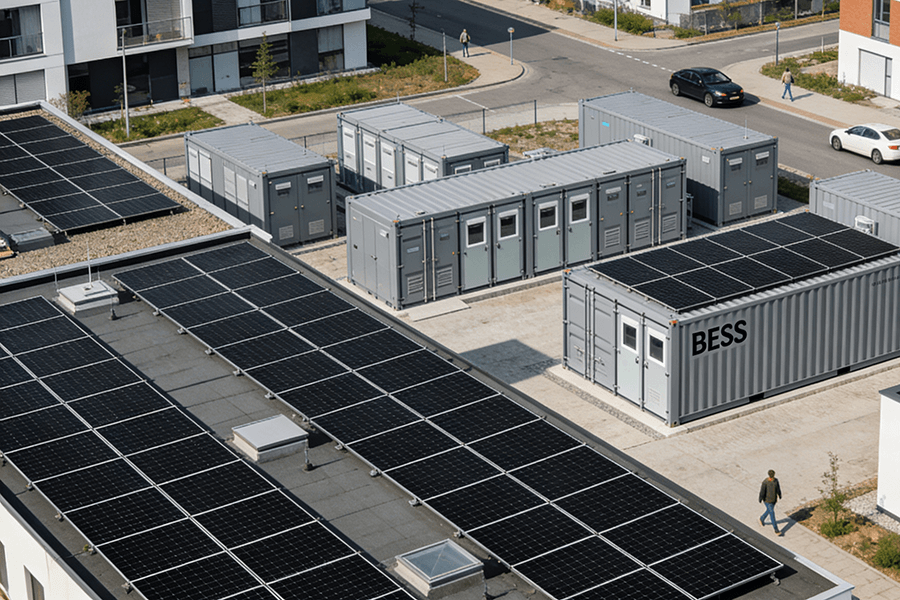

Remote Intelligent Scheduling: Unmanned O&M That Actually Works

Forget sending teams to remote wind farms in the North Sea or desert solar plants—where travel costs alone can hit $10,000 per trip. AI-powered remote monitoring lets one engineer manage 10+ BESS sites from a laptop in a climate-controlled office.

The EU’s 1.2 GW North Sea offshore project is a perfect example: Its marine-grade BESS containers are monitored 24/7 from a control room in Amsterdam, with zero on-site O&M staff. AI auto-generates work orders only when something actually needs fixing—no more “preventive” visits that waste time and money (Maxbo Solar, 2025).

The Numbers Don’t Lie: AI BESS ROI in Black and White

Humor aside, the business case for AI BESS is irrefutable. Below is a side-by-side comparison of a 100 MWh BESS farm with traditional vs. AI-powered O&M, based on 2025 industry averages and real customer data. The ROI? Typically under 18 months.

|

Metric

|

Traditional O&M

|

AI-Powered O&M

|

Quantifiable Improvement

|

|---|---|---|---|

|

Annual O&M Cost

|

$420,000

|

$252,000

|

40% reduction ($168k/year savings)

|

|

Fault Repair Time

|

48 hours

|

14.4 hours

|

70% faster (minimized downtime)

|

|

Battery Cycle Life

|

6,500 cycles

|

7,475 cycles

|

15% longer (extends asset life by 1.5+ years)

|

|

Manual Intervention Hours/Month

|

180 hours

|

36 hours

|

80% reduction (frees staff for critical tasks)

|

|

Annual Revenue (Grid Services)

|

$1.2M

|

$1.5M

|

25% increase ($300k/year extra revenue)

|

How It Works: The Tech Behind the “Self-Diagnosing” BESS

You don’t need a PhD in computer science to understand this—think of it as a “data pipeline” with three simple, rock-solid steps. Every component is built for industrial use, so it works in dust, rain, and extreme temperatures (-20°C to 55°C).

-

Edge Computing Modules: The Eyes and EarsWe embed rugged, IP68-rated sensors and edge AI chips directly in the BESS container. These modules collect 50+ data points per second (temperature, voltage, current, vibration) and filter out “noise” (like temporary voltage spikes) locally. No lag, no cloud overload—just clean, actionable data.

-

Cloud Platform: The BrainThe filtered data syncs to our secure cloud platform (ISO 27001 certified), where machine learning algorithms go to work. These algorithms are trained on 10+ years of BESS performance data from 500+ deployments. They compare your BESS’s behavior to thousands of others, spot anomalies, and generate optimization recommendations—all in under 2 seconds.

-

Local Execution: The MusclesThe cloud sends commands back to the BESS’s control system, which adjusts charging/discharging, triggers cooling, or alerts your team (via email/SMS) if action is needed. If the internet goes down? No problem—the edge module keeps running pre-set optimizations until connectivity is back. It’s fail-safe by design.

Why Maxbo Solar’s AI BESS Is Your Best Bet (From the Team That Built It)

We’re not just selling BESS containers—we’re selling peace of mind. As engineers who’ve spent a decade fixing the flaws of traditional energy storage, we built our AI BESS to solve the problems you actually face: unexpected outages, sky-high O&M bills, and tech that doesn’t play nice with your systems. Here’s what makes us different:

Customized Algorithms: Built for Your Use Case

Generic AI doesn’t cut it. If you’re running a microgrid in the North Sea, your BESS needs to prioritize storm resilience and fuel savings. If you’re a factory in Berlin, it needs to focus on peak demand reduction. We tailor our ML models to your unique environment (temperature, load patterns, grid rules) and update them quarterly based on your data.

No “one-size-fits-all” garbage—just AI that works for you, right out of the box.

Multi-Platform Compatibility: Plays Nice With Your Tools

Tired of tech that doesn’t integrate with your existing SCADA, energy management system (EMS), or ERP? Our AI platform uses open APIs and supports all major industry protocols (Modbus, DNP3, IEC 61850). That means you don’t have to rip and replace your current tools—we plug right in.

We’ve integrated with systems from Siemens, ABB, and Schneider, so chances are we already speak your “tech language.” No integration headaches, no extra IT costs.

24/7 Intelligent Support: AI + Human Expertise

Our support doesn’t end with installation. Here’s what sets our after-sales service apart:

-

Round-the-Clock AI Monitoring: Our cloud platform tracks your BESS’s health 24/7, sending instant alerts for anomalies (e.g., abnormal cell temperature, voltage fluctuations).

-

Human Backup Team: Every alert is reviewed by our in-house energy storage engineers (based in Germany and Spain) within 15 minutes. No more automated tickets that go unaddressed.

-

On-Site Coordination: If on-site service is needed, we partner with 200+ certified technicians across Europe to ensure a response time of 4–8 hours in major regions.

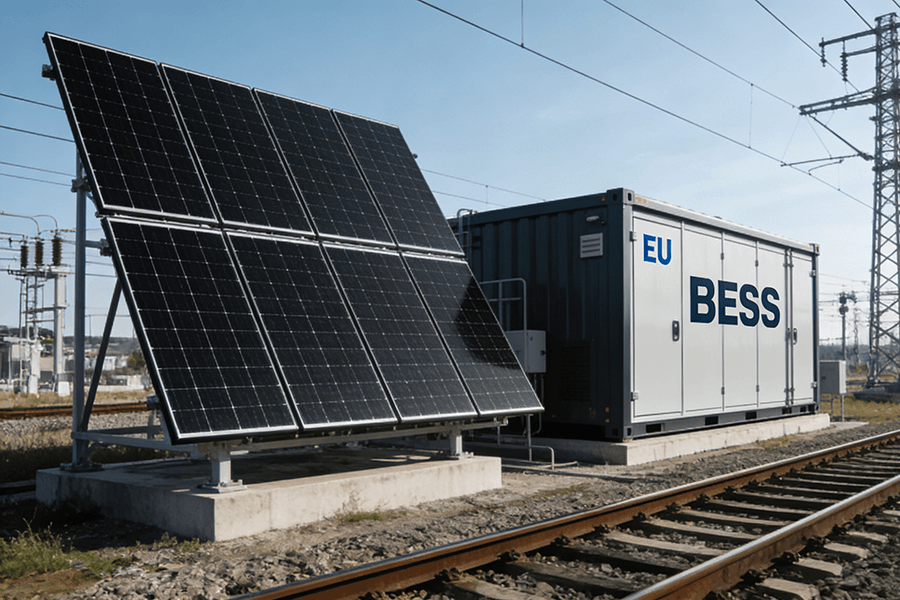

Rugged, Future-Proof Hardware

Our BESS containers are built to last—and adapt. Key hardware features include:

-

Extreme Environment Resistance: Marine-grade steel enclosure, IP68-rated components, and dual-circuit cooling systems that operate in -20°C to 55°C and 95% humidity.

-

Scalable Design: Easily add more battery modules or upgrade AI chips without replacing the entire container—supports capacity expansion by up to 50%.

-

Long Warranty Coverage: 10-year warranty on the container structure, 8-year warranty on battery modules, and 5-year warranty on the AI control system.

Transparent Data & Reporting

We believe you should have full visibility into your BESS’s performance. Our cloud platform offers:

-

Customizable Dashboards: Track key metrics (O&M costs, battery health, revenue) in real time, with export options for Excel/PDF.

-

Quarterly Performance Reports: Our engineers analyze your data to identify optimization opportunities (e.g., adjusting discharge times for higher grid prices) and share actionable insights.

-

Compliance Documentation: Auto-generate reports to meet EU energy storage regulations (e.g., EN 50530, IEC 62933) and simplify audits.